Clad powder for powdered iron core and preparation process for clad powder

A technology of coating powder and powdered iron core, applied in the direction of coating, etc., can solve the damage to the comprehensive performance of the powdered iron core such as mechanical properties and magnetic properties, the powdered iron core cannot replace the laminated iron core, and the limited coating Powder promotion and application, etc., to achieve the effect of high utilization rate of raw materials, reduced thickness, and simple manufacturing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

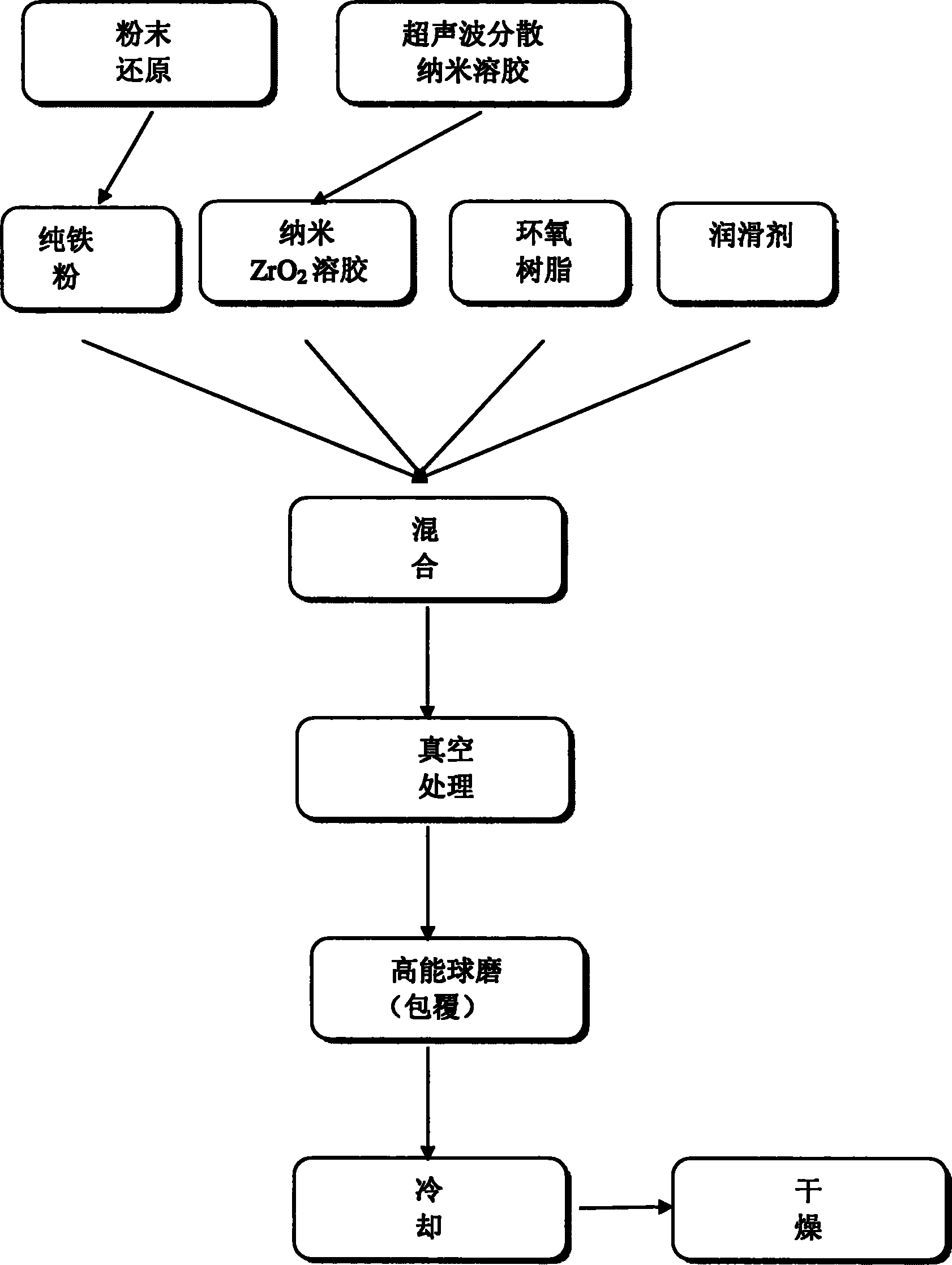

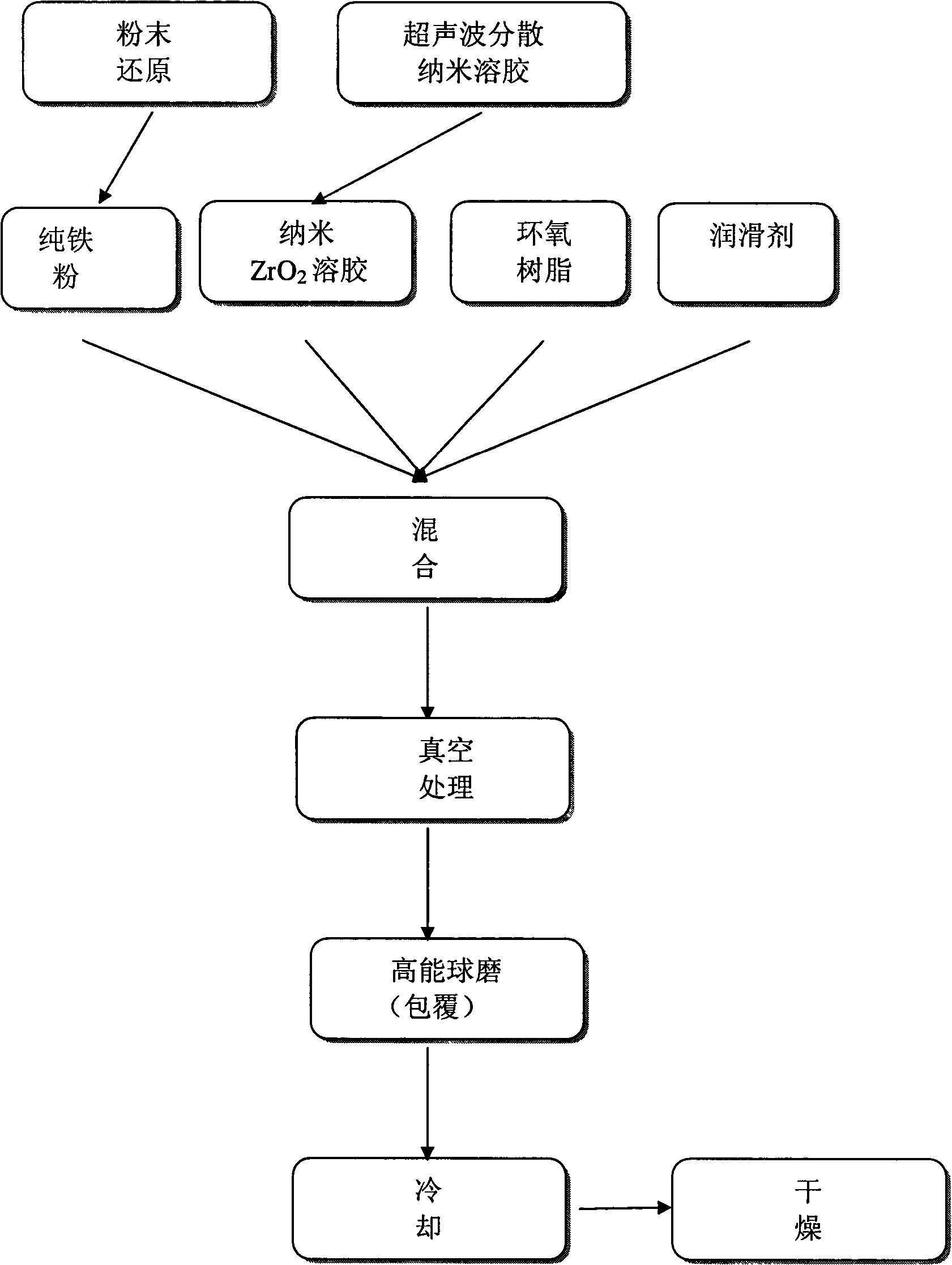

[0027] The present invention will be further described below in conjunction with drawings and embodiments.

[0028] (1) First mix iron powder, epoxy resin powder, and zinc stearate powder with a weight ratio of 1:1%:1.5%, wherein the mass of iron powder accounts for 97.6% of the total; Nano ZrO 2 The sol, whose mass fraction is 3% of the iron powder mass, after mixing evenly, add ethanol grinding medium and pour it into the ball milling tank of the planetary ball mill, and then vacuumize it, and the vacuum degree is 0.8×10 -2 Pa; two kinds of stainless steel balls with diameters of 4mm and 6mm are used for the grinding balls, and the ball-to-material ratio is 12:1; the mass ratio of small and large grinding balls is 1.5:1. Then rotate at a high speed of 450r / min for 3h, cool to room temperature, and finally perform drying treatment to obtain the coated powder of the present invention. Among them, the iron powder realizes the insulating coating between the particles, and at t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com