Method for preparing porous silicon-nitride ceramic material

A silicon nitride ceramic and silicon nitride technology, applied in ceramic products, other household appliances, household appliances, etc., can solve the problems of high open porosity and low density, and achieve the effect of low density and high open porosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

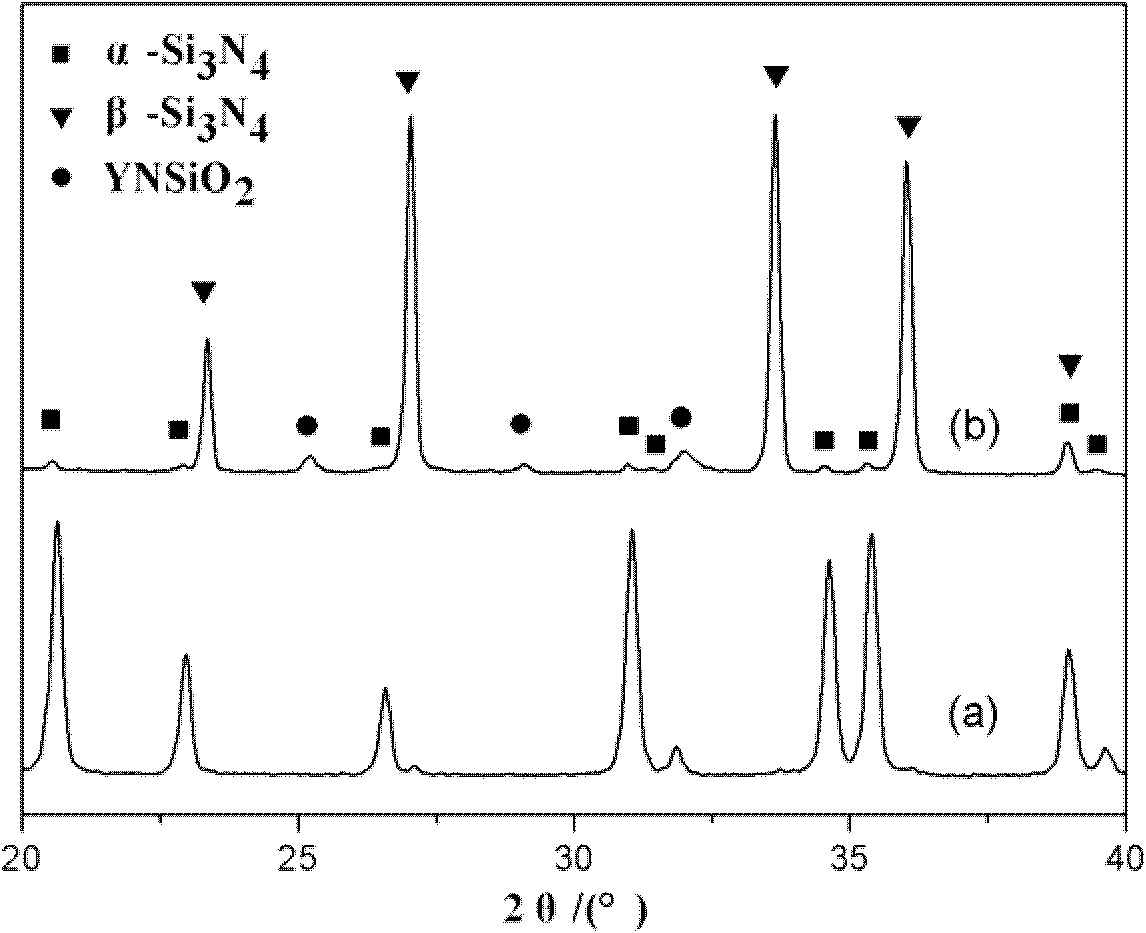

Method used

Image

Examples

Embodiment 1

[0031] a) Stir 8 g of starch and 75 g of deionized water vigorously at 70° C. for 10 minutes to make it absorb water and swell to obtain pregelatinized starch;

[0032] b) Transfer the prepared pregelatinized starch to the ball mill tank, then add 50g silicon nitride, 2.5g sintering aid yttrium oxide, 2g binder polyvinyl alcohol and 1g defoamer n-octanol to the ball mill In the tank, the ball mill is used to make the mixture uniform, and the mixed slurry is obtained;

[0033] c) Cast the mixed slurry prepared in step b), and then put it into a vacuum drying oven at room temperature below 100Pa to vacuum degas for 15 minutes to eliminate the air bubbles in the slurry; then seal the sample and put it in an oven at 85°C Internal solidification for 30 minutes, after cooling to room temperature, place the sample in a low-temperature refrigerator at -30°C for 24 hours to completely freeze the sample; quickly transfer the frozen sample to a freeze dryer at 5°C and 10Pa Freeze drying...

Embodiment 2

[0040] a) Stir 8 g of starch and 70 g of deionized water vigorously at 90° C. for 5 minutes to make it absorb water and swell to obtain pregelatinized starch;

[0041] b) Transfer the prepared pregelatinized starch to the ball mill tank, then add 50g silicon nitride, 2g sintering aid yttrium oxide, 2g binder polyvinyl alcohol and 1.2g defoamer n-octanol to the ball mill In the tank, the ball mill is used to make the mixture uniform, and the mixed slurry is obtained;

[0042] c) Cast the mixed slurry prepared in step b), and then put it into a vacuum drying oven at room temperature below 100Pa for 20 minutes of vacuum degassing to eliminate the air bubbles in the slurry; then seal the sample and put it in an oven at 70°C Solidify within 60 minutes. After cooling to room temperature, place the sample in a low-temperature refrigerator at -30°C for 24 hours to completely freeze the sample; Freeze-drying for 24 hours to sublimate the ice crystals in the frozen body to form a porou...

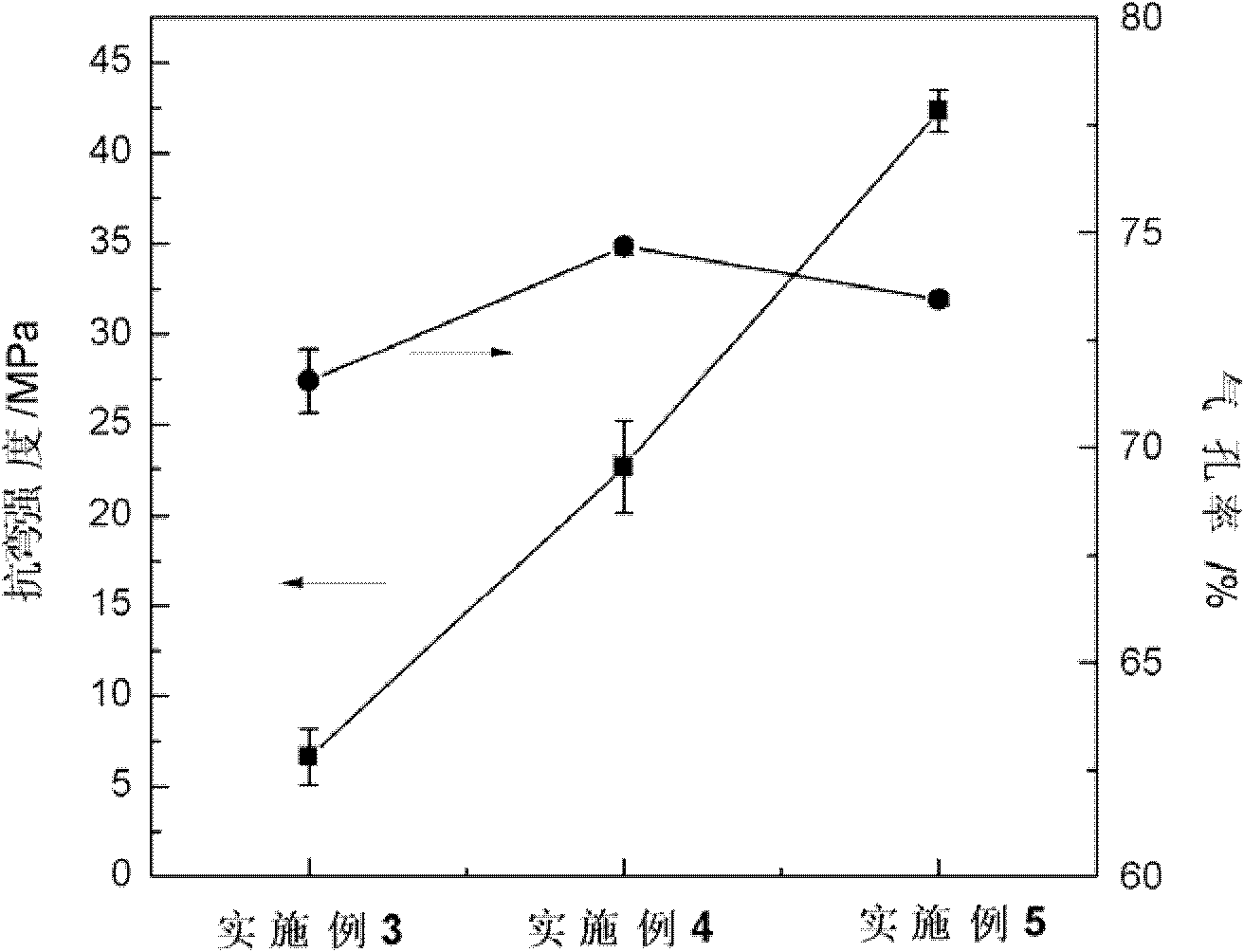

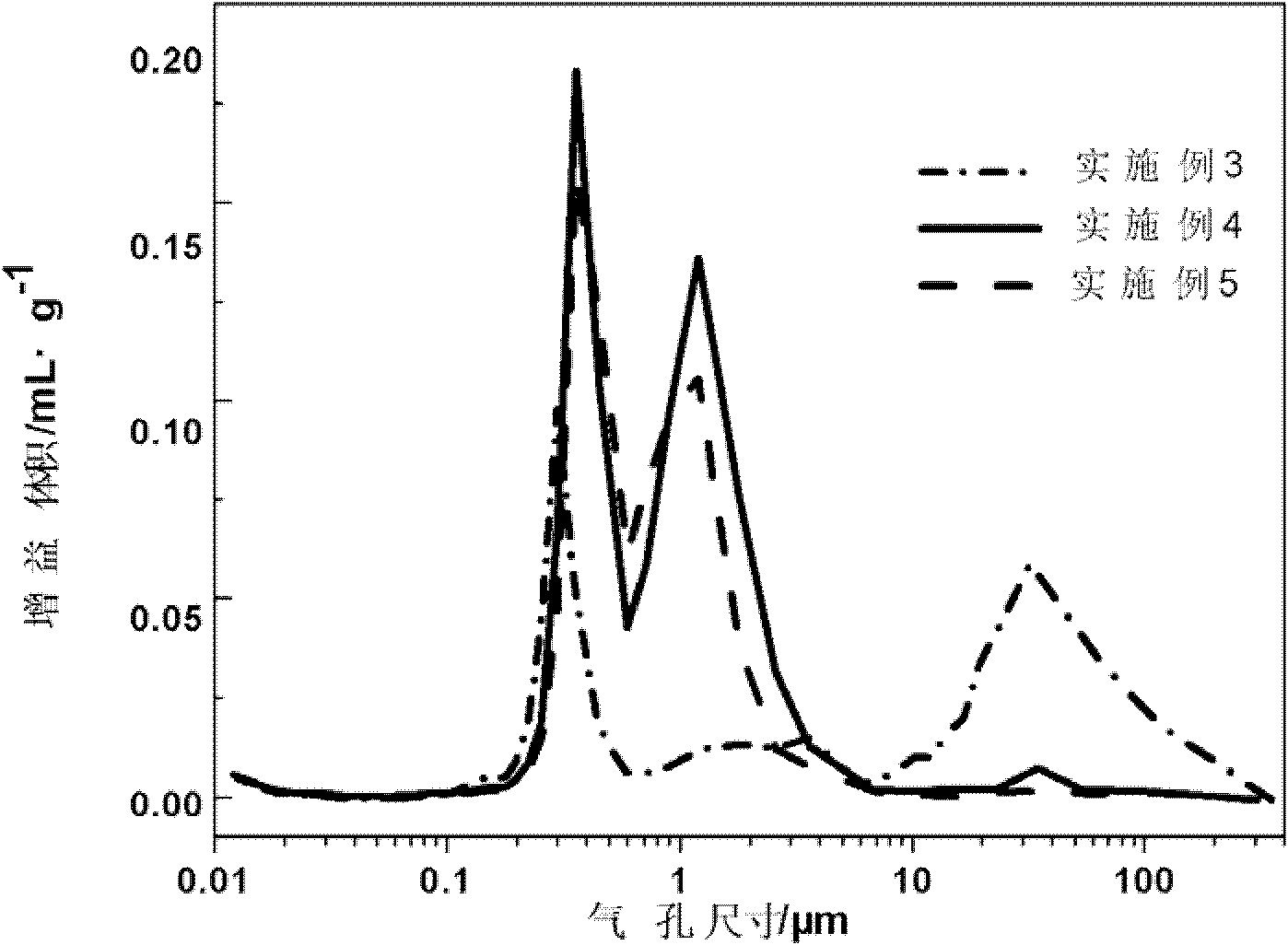

Embodiment 3

[0047] a) Stir 5 g of starch and 60 g of deionized water vigorously at 70° C. for 10 minutes to make it absorb water and swell to obtain pregelatinized starch;

[0048] b) the prepared pregelatinized starch is transferred to the ball mill tank, then 50g silicon nitride, 2.5g sintering aid yttrium oxide, 0g binder polyvinyl alcohol and 0.8g defoamer n-octanol are added to the In the ball milling tank, the ball milling makes the mixing uniform and makes the mixed slurry;

[0049] c) Cast the mixed slurry prepared in step b), and then put it into a vacuum drying oven at room temperature below 100Pa for 20 minutes of vacuum degassing to eliminate the air bubbles in the slurry; then seal the sample and put it in an oven at 70°C Solidify within 60 minutes. After cooling to room temperature, place the sample in a low-temperature refrigerator at -30°C for 24 hours to completely freeze the sample; Freeze-drying for 24 hours to sublimate the ice crystals in the frozen body to form a po...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Bending strength | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com