Manufacturing method of medium-high pressure chemical foil

A manufacturing method and a technology for forming foils, which are applied in electrical components, electrolytic capacitors, capacitors, etc., can solve the problems of reduced specific surface area, reduced electrostatic capacitance of electrode foils, and destruction of electrostatic capacitance, and achieves improved specific capacitance, remarkable effect, and improved water resistance. performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

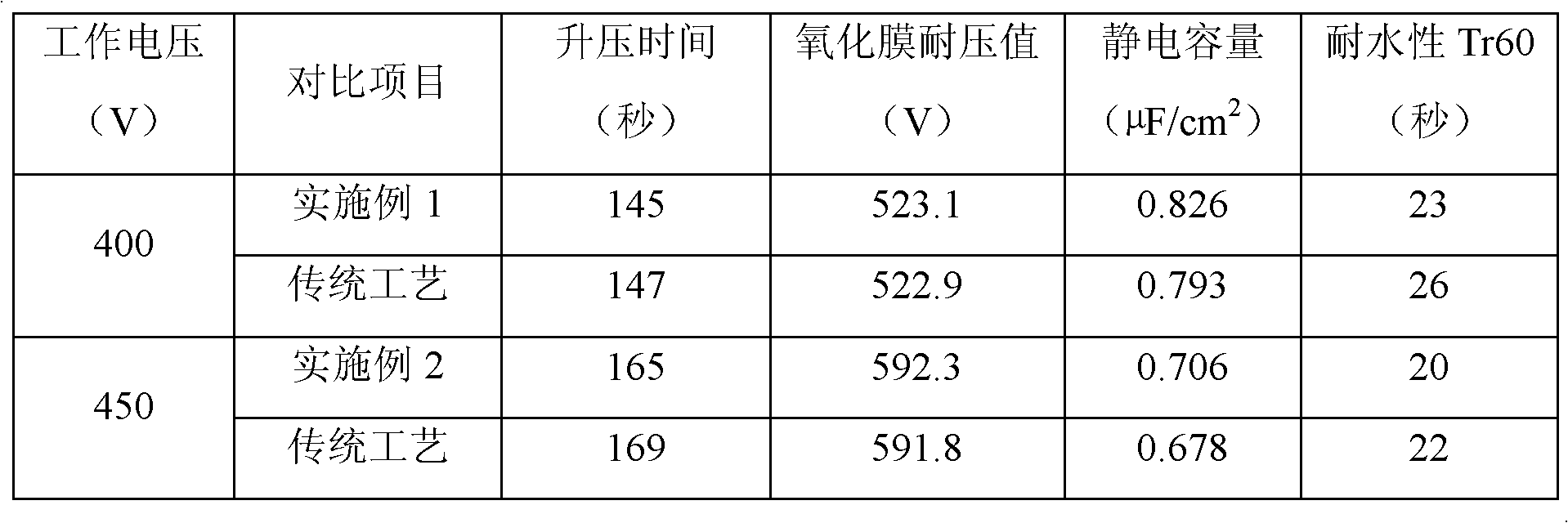

Embodiment 1

[0036] Make the aluminum foil that working voltage is 400V according to the method of the present invention, it is 520V to set highest forming voltage (forming voltage), specifically as follows:

[0037] 1) Put the corroded and expanded aluminum foil in 0.1mL / L alkylphenol polyoxyethylene ether OP-10 wetting dispersion, soak at 40°C for 3min, and its HLB value is 13.3-14.5;

[0038] 2 Put the soaked aluminum foil into pure water ≥ 97°C and boil for 8 minutes;

[0039] 3) Place the boiled aluminum foil again in 0.1mL / L wetting dispersion of alkylphenol polyoxyethylene ether OP-10 for 2min at 30°C;

[0040] 4) The re-wetted aluminum foil is subjected to primary formation in 5% borate solution at 85°C, boosted to 156V and then kept at constant pressure for 15 minutes;

[0041] 5) The aluminum foil after primary formation is subjected to secondary formation in 5% borate solution at 85°C, boosted to 312V and then kept at constant pressure for 15 minutes;

[0042] 6) The aluminum ...

Embodiment 2

[0054] Make the aluminum foil that working voltage is 450V according to the method of the present invention, it is 590V to set highest forming voltage (forming voltage), specifically as follows:

[0055] 1) Put the corroded and expanded aluminum foil in 0.15mL / L nonylphenol polyoxyethylene ether NP-7 wetting dispersion, soak at 30°C for 4min, and its HLB value is 11.7-12;

[0056] 2) Put the infiltrated aluminum foil into pure water ≥ 97°C and boil for 10 minutes;

[0057] 3) Place the boiled aluminum foil in 0.15mL / L nonylphenol polyoxyethylene ether NP-7 wetting dispersion again, and soak at 25°C for 2min;

[0058] 4) The re-wetted aluminum foil was subjected to primary formation in 5% borate solution at 85°C, boosted to 177V and then kept at constant pressure for 15 minutes;

[0059] 5) The aluminum foil after primary formation is subjected to secondary formation in 5% borate solution at 85°C, boosted to 354V and then kept at constant pressure for 15 minutes;

[0060] 6) ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com