Oil and fat composition

A technology of oil and fat composition and emulsified composition, applied in the directions of edible oil/fat, food science, baking, etc., can solve the problems of insufficient bread quality, inability to stabilize bubbles, easy crystallization, etc., and achieve brittleness and good flavor , Excellent emulsification stability, the effect of inhibiting crystallization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

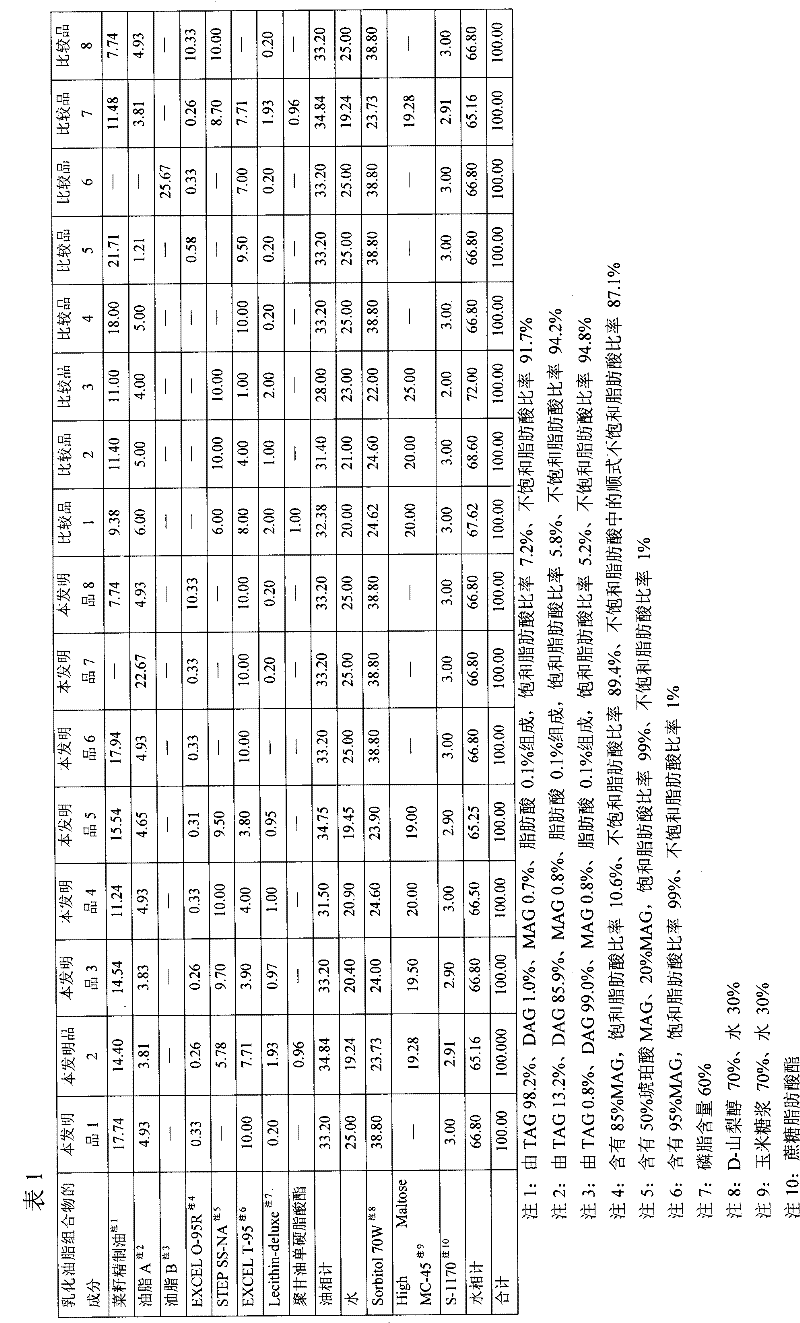

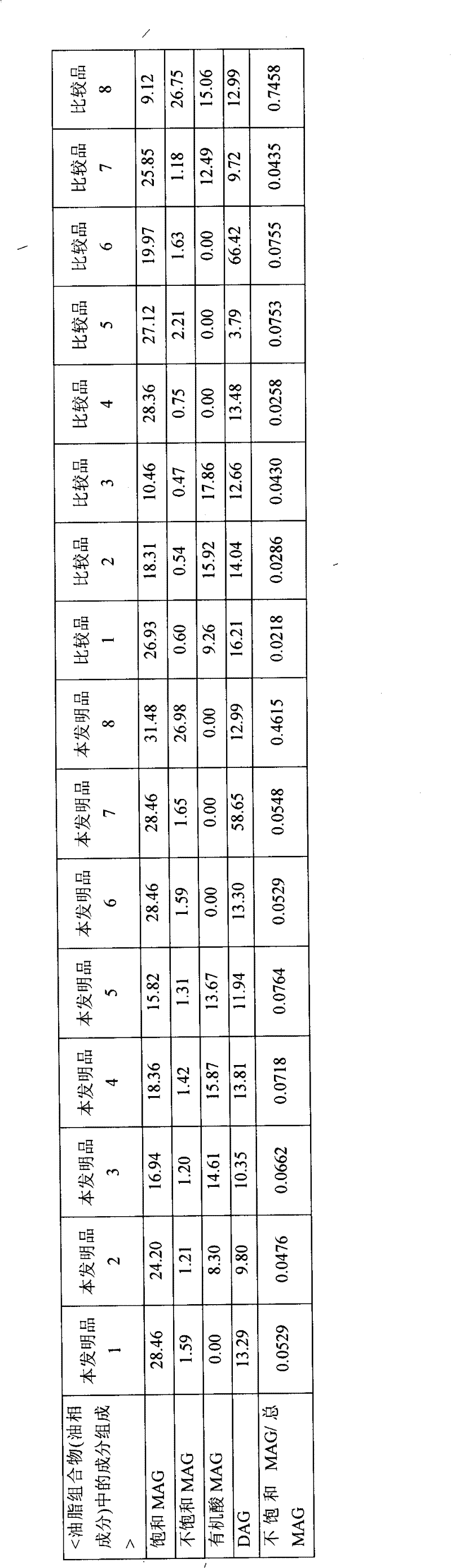

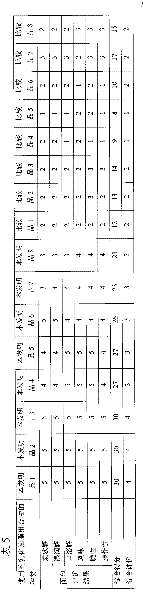

[0058] Hereinafter, the present invention will be described in detail based on examples, but the present invention is not limited to these examples.

[0059] In addition, in the following examples, TAG means triacylglycerol, DAG means diacylglycerol, and MAG means monoacylglycerol, and unless otherwise indicated, the numerical value indicating the component composition means mass %.

[0060] [Analytical method]

[0061] Acylglycerol Composition:

[0062] About 10 mg of a fat sample and 0.5 mL of a trimethylsilylating agent ("silylating agent TH", manufactured by Kanto Chemical Co., Ltd.) were added to a glass sample bottle, sealed, and heated at 70° C. for 15 minutes. 1.0 mL of water and 1.5 mL of hexane were added thereto and shaken. After standing still, the upper layer was subjected to gas chromatography (GLC) and analyzed.

[0063] Composition of fatty acids:

[0064] Fatty acid methyl esters were prepared according to "01 preparation method of fatty acid methyl esters...

preparation example 1

[0068] [Preparation Example 1 Preparation of Oil Composition]

[0069] Rapeseed refined oil (manufactured by Nisshin OilliO Group Ltd.), diacylglycerol-containing oil (the above oil A or the above oil B), unsaturated monoacylglycerol (trade name: EXCEL O-95R, Kao company), succinic acid monoacylglycerol (trade name: STEP SS-NA, manufactured by Kao Corporation), saturated monoacylglycerol (EXCEL T-95, manufactured by Kao Corporation), lecithin (trade name: Lecithin-delux, Nisshin OilliO Group Ltd.) and polyglyceryl monostearate (manufactured by Kao Corporation), were dissolved under heating and stirring at 80° C. to prepare an oil composition.

preparation example 2

[0070] [Preparation Example 2 Preparation of Emulsified Composition]

[0071] Mix sorbitol (trade name: Sorbitol 70W, produced by Kao Corporation), maltose (trade name: High Maltose MC-45, produced by Nippon Food & Chemical Co., Ltd.), sucrose fatty acid ester (S-1170, produced by Mitsubishi Corporation) in the ratio shown in Table 1. Kagaku Co., Ltd.) and water were dissolved by heating and stirring at 40° C. to obtain an aqueous phase component.

[0072] In addition, the numerical value of each component described in the upper column of Table 1 shows the mass % when the total mass of an oil phase component and a water phase component is 100%.

[0073] While gradually adding the above-mentioned water phase component to the oil and fat composition (oil phase component) obtained in Preparation Example 1, using a homogenizer (manufactured by Tokuki Kagaku Kogyo Co., Ltd.), stirring and emulsifying at 50° C. at 7000 rpm to obtain Invention products 1-8 and comparative products 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com