Preparation method of cobalt nanoparticle/carbon nanotube composite material

A carbon nanotube and composite material technology, applied in chemical instruments and methods, chemical/physical processes, physical/chemical process catalysts, etc., can solve the problem of low cobalt loading, damage to the surface structure of carbon nanotubes, and complex cobalt nanoparticle processes. and other problems to achieve the effect of maintaining the surface structure and performance and simplifying the reaction steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

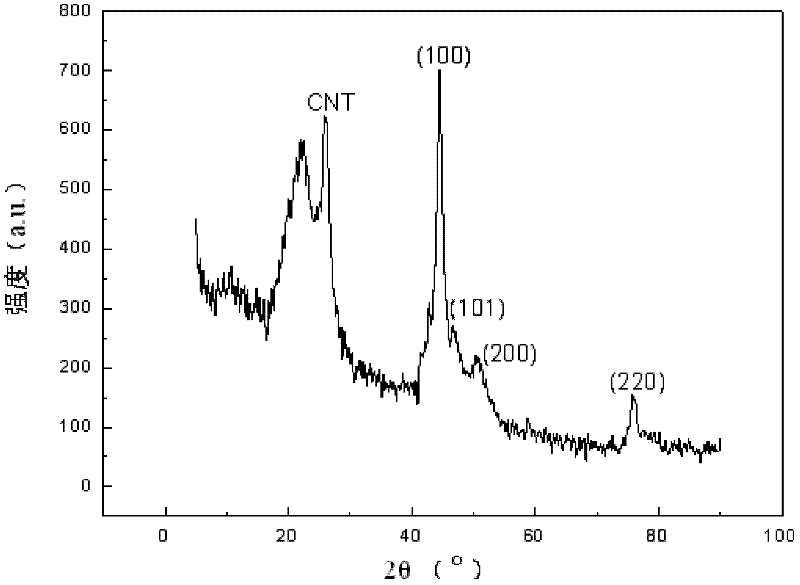

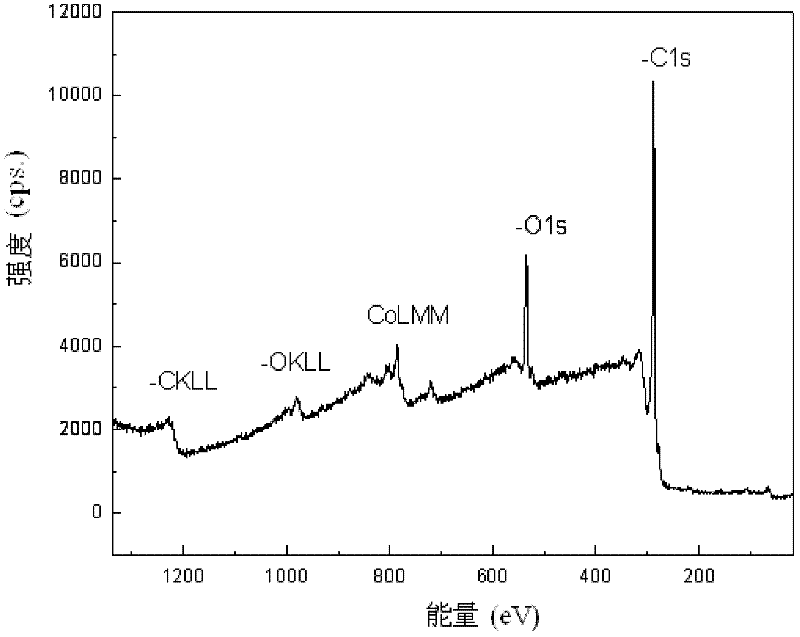

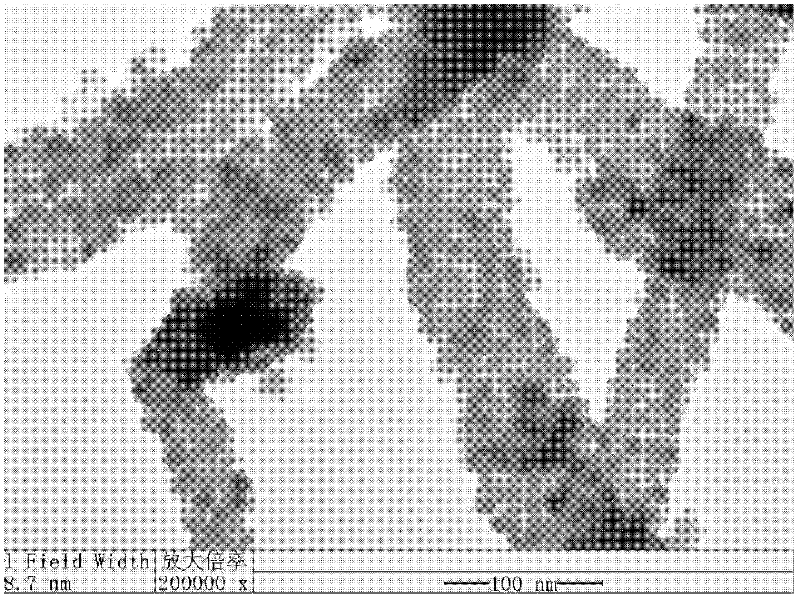

[0009] Specific embodiment one: the preparation method of a kind of cobalt nanoparticle / carbon nanotube composite material of the present embodiment is carried out according to the following steps: one, weigh carbon nanotube, cobalt acetylacetonate and triethylene glycol and add in the container and mix uniformly , and then placed in an ultrasonic cleaning machine for 10min to 30min to obtain a mixed solution; wherein the mass ratio of carbon nanotubes to cobalt acetylacetonate is 1:1 to 4, the volume y of triethylene glycol and the quality x of carbon nanotubes satisfy function:

[0010] y=25(m+1), x∈(50m, 50(m+1)], m=0,1,2,...; the unit of y is mL, and the unit of x is g; two, the step Add the obtained mixed solution into the reactor with cooling reflux device, pass through the argon gas protection, then raise the temperature to boiling at the speed of 2°C / min~4°C / min, and keep the reflux for 30min~60min, and then lower to normal temperature , to obtain a mixed solution con...

specific Embodiment approach 2

[0012] Embodiment 2: This embodiment differs from Embodiment 1 in that: the ultrasonic treatment time in Step 1 is 12 min to 25 min. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0013] Embodiment 3: The difference between this embodiment and Embodiment 1 is that the ultrasonic treatment time in Step 1 is 20 minutes. Others are the same as in the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com