Method for repairing support body for preparing molecular sieve membrane

A repair method and molecular sieve technology, applied in the field of supports, can solve problems such as unfavorable molecular sieve membranes, large pores on the surface of supports, etc., and achieve the effects of improving binding effect, improving overall performance and qualification rate, and avoiding the formation of defects from collapse again.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

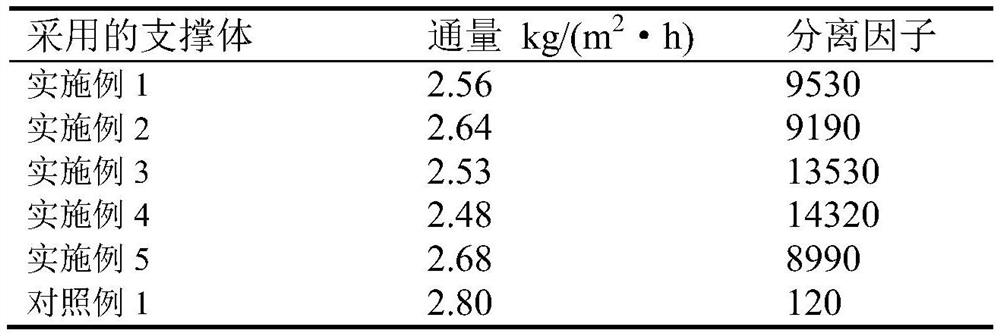

Embodiment 1

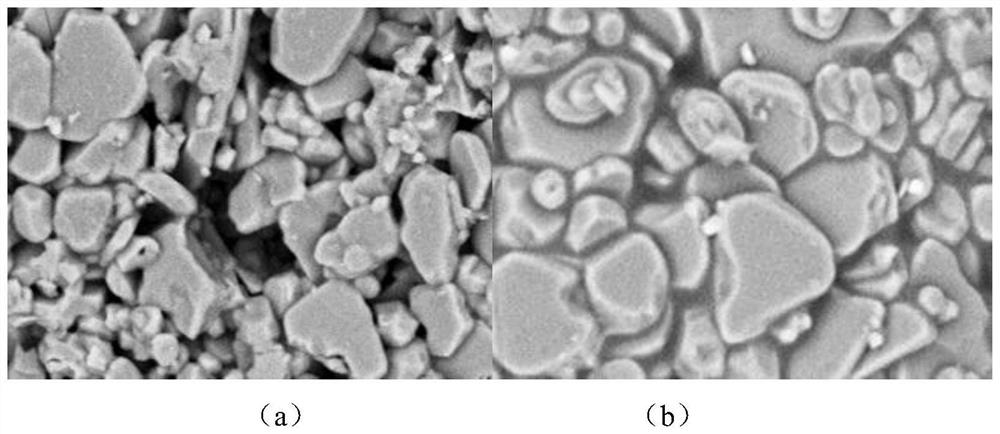

[0032] 1) The average pore size is 2umAl 2 o 3 The surface of the ceramic support body is cleaned and dried for use;

[0033] 2) Al with an average particle size of 30um 2 o 3 Add the powder into the water, stir evenly, and the solid content in the water is 8%;

[0034] 3) NaA molecular sieve raw powder is added to the above suspension, and the amount of NaA molecular sieve raw powder added is 5% of the above solids;

[0035] 4) Add binder and dispersant to continue to disperse evenly;

[0036] 5) coating the suspension on the surface of the ceramic support by dip coating;

[0037] 6) Drying and heat preservation at 1400° C. for 2 hours to obtain the repaired support.

Embodiment 2

[0039] 1) Clean the surface of the ceramic support body with an average pore size of 3um, and dry it for later use;

[0040] 2) Al with an average particle size of 30um 2 o 3 Add the powder into the water, stir evenly, and the solid content in the water is 5%;

[0041] 3) NaA molecular sieve raw powder is added to the above suspension, and the amount of NaA molecular sieve raw powder added is 10% of the above solids;

[0042] 4) Add binder and dispersant to continue to disperse evenly;

[0043] 5) Coating the above-mentioned suspension on the surface of the ceramic support by a wiping method;

[0044] 6) Drying and heat preservation at 1300° C. for 3 hours to obtain the repaired support.

Embodiment 3

[0046] 1) The average pore size is 2umAl 2 o 3 The surface of the ceramic support body is cleaned and dried for use;

[0047] 2) Al with an average particle size of 30um 2 o 3 Add the powder into the water, stir evenly, and the solid content in the water is 8%;

[0048] 3) NaA molecular sieve raw powder is added to the above suspension, and the amount of NaA molecular sieve raw powder added is 5% of the above solids;

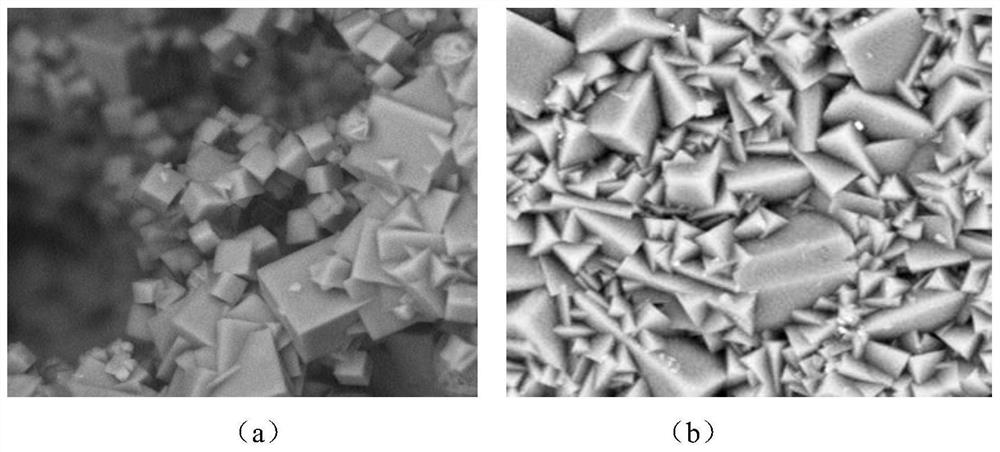

[0049] 4) Add 3% kerosene to the above suspension, stir at high speed so that the diameter of the formed bubbles ranges from 80-120um, and carry out cyclone air flotation treatment through a cyclone air flotation device with a diameter of 0.4m, and add water to the foam phase to dilute to a solid content of 8.4 %, the water phase is dehydrated to the same concentration;

[0050] 4) Add binder and dispersant to the above-mentioned foam phase and water phase respectively to continue to disperse evenly;

[0051] 5) Coating the above-mentioned suspension on th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com