Method for improving adhesion property of aluminum foil for anode of lithium ion battery

A lithium-ion battery, a technology of bonding performance, applied to the device for coating liquid on the surface, pre-treating the surface, coating, etc., can solve the problem of improving the performance of the positive electrode binder, reducing the binder content, and sticking Poor performance and other problems, to achieve the effect of improving bondability, improving bonding performance, and reducing the amount of adhesive

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] Take 2 samples of aluminum foil for lithium-ion batteries, one of which is not treated with plasma, and is marked as sample 1; the other is treated with plasma, the plasma power is 0.6KW, and the distance between the nozzle of the plasma spray gun and the aluminum foil is 5mm. The speed of the aluminum foil is 20m / min, which is marked as sample 2. Use the surface tension energy test ink (60mN / m) to test the surface energy of sample 1 and sample 2 respectively, see the effect photos for details figure 1 , 2 .

[0016] From the above experimental results, it can be seen that after plasma treatment, the surface properties of the aluminum foil have been greatly improved, and the adhesiveness has been significantly improved.

Embodiment 2

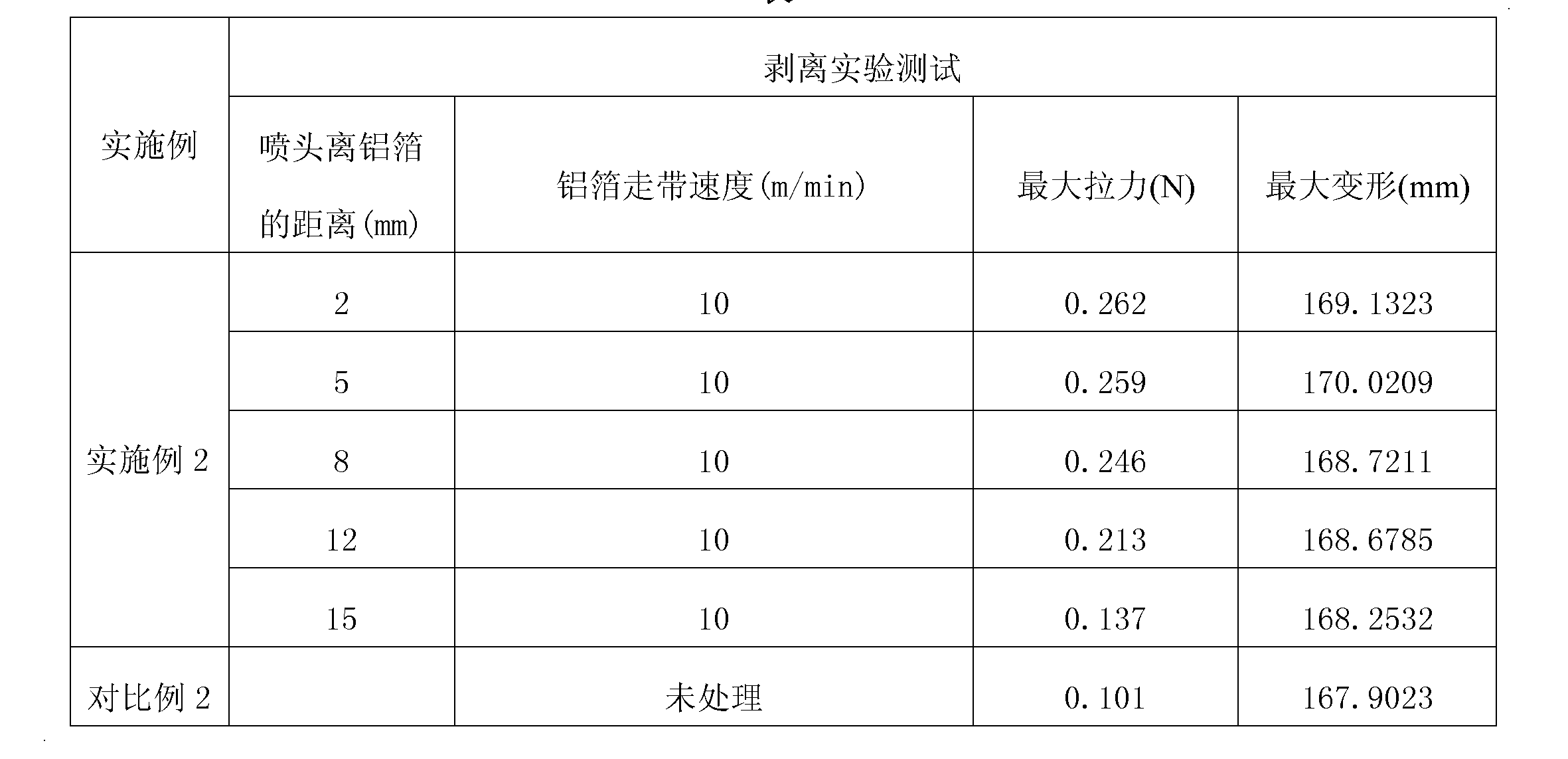

[0018] Lithium cobalt oxide (LiCoO 2 ) as a positive electrode active material, conductive carbon black (SP) as a conductive agent, and polyvinylidene fluoride (PVDF) as a binder, the ratio of which is 96.2:1.9:1.9, mixed and prepared into a positive electrode active material slurry with a viscosity of 5800cP, Then be coated on the aluminum foil of untreated comparative example 2 and normal pressure plasma treatment embodiment 2 respectively, wherein the adjustment experiment is carried out in different processes during plasma treatment, the plasma power is 0.8KW, and the plasma spray gun is installed before the coating machine head, The length of the aluminum foil between the spray gun and the two points of the machine head is about 3m. The distance between the nozzle of the spray gun and the aluminum foil is adjusted to 2mm, 5mm, 8mm, 10mm, and 12mm respectively. The speed of the aluminum foil is 10m / min. Then make the positive electrode. The peeling performance of the posi...

Embodiment 3

[0023] Nano lithium iron phosphate (LiFePO 4 ) as the positive electrode active material, conductive carbon black (SP) and carbon nanotubes (CNT) as the conductive agent, polyvinylidene fluoride (PVDF) as the binder, the ratio is 93.5:1.5:1.5:3.5, mixed to form a viscosity Be the positive electrode active material slurry of 4200cP, then be respectively coated on the aluminum foil of the embodiment 3 of the comparative example 3 that is not processed and normal pressure plasma treatment, wherein plasma treatment is divided into different processes to carry out the adjustment experiment, and the plasma spray gun is installed on the coating machine In front of the head, the plasma power is 1KW, the length of the aluminum foil between the spray gun and the machine head is about 3m, the distance between the nozzle of the spray gun and the aluminum foil is adjusted to 4mm, and the speed of the aluminum foil is adjusted to 6m / min, 9m / min, 12m / min, 15m / min, coated immediately after t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com