Corrosion resisting and shock resisting steel with high strength and preparation method thereof

A technology of corrosion-resistant and earthquake-resistant steel, applied in the direction of temperature control, etc., can solve the problems of difficult construction, uncertain anti-corrosion effect, high cost, etc., to improve passivation corrosion resistance, strong process applicability and controllability, and improve use The effect of longevity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

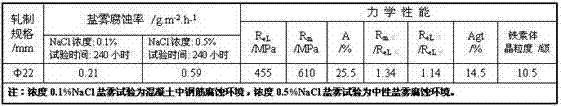

Embodiment 1

[0042] A. Put molten iron, scrap steel, pig iron and slagging agent into the LD steelmaking converter according to the routine, carry out the conventional top-bottom compound blowing, and make slag according to the routine, control the carbon content of the end point to 0.03 wt%, and the tapping temperature to 1680 ℃ , and before tapping, add lime and fluorite to the bottom of the ladle, the addition amount is controlled as lime 3kg / t steel, fluorite 0.4 kg / t steel, and then tap;

[0043] B. During the tapping process, when the amount of molten steel in the ladle reaches 1 / 5, deoxidation and alloying treatment is carried out, that is, composite deoxidizer, silicon-manganese alloy, ferrosilicon, medium carbon ferrochromium, ferro-niobium, and vanadium are sequentially added to the ladle Nitrogen alloy, and when ladle molten steel amount reaches 3 / 4, add described each alloy, the add-on of each alloy is:

[0044] Composite deoxidizer 0.8 kg / t steel,

Embodiment 2

[0063] A. Put molten iron, scrap steel, pig iron and slagging agent into the LD steelmaking converter according to the routine, carry out the conventional top-bottom compound blowing, and make slag according to the routine, control the carbon content of the end point to 0.06 wt%, and the tapping temperature to 1680 ℃ , and before tapping, add lime and fluorite to the bottom of the ladle, and the amount of addition is controlled as lime 2kg / t steel and fluorite 0.6 kg / t steel;

[0064] B. During the tapping process, when the amount of molten steel in the ladle reaches or exceeds 1 / 5, deoxidation and alloying treatment is carried out, that is, composite deoxidizer, silicon-manganese alloy, ferrosilicon, medium-carbon ferrochrome, and ferroniobium are sequentially added to the ladle , vanadium-nitrogen alloy, and when the ladle molten steel amount reaches 3 / 4, add described each alloy, the addition of each alloy is:

[0065] Composite deoxidizer 0.9 kg / t steel,

[0066] Silicon ...

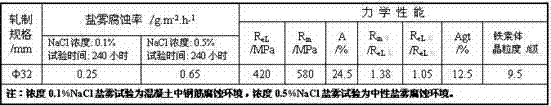

Embodiment 3

[0084] A. Put molten iron, scrap steel, pig iron and slagging agent into the LD steelmaking converter according to the routine, carry out the conventional top-bottom compound blowing, and make slag according to the routine, control the carbon content of the end point to 0.05 wt%, and the tapping temperature to 1680 ℃ , and before tapping, add lime and fluorite to the bottom of the ladle, and the addition amount is controlled as lime 3kg / t steel and fluorite 0.5 kg / t steel;

[0085] B. During the tapping process, when the amount of molten steel in the ladle reaches or exceeds 1 / 5, deoxidation and alloying treatment is carried out, that is, composite deoxidizer, silicon-manganese alloy, ferrosilicon, medium-carbon ferrochrome, and ferroniobium are sequentially added to the ladle , vanadium-nitrogen alloy, and when the ladle molten steel amount reaches 3 / 4, add described each alloy, the addition of each alloy is:

[0086] Composite deoxidizer 1.0 kg / t steel,

[0087] Silicon man...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com