Mica paper and production method and application thereof

A technology of powdered mica paper and powdered mica, applied in the direction of winding insulation materials, etc., can solve the problems of insufficient insulation impregnation, high viscosity, etc., and achieve the effect of improving air permeability and excellent electrical insulation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

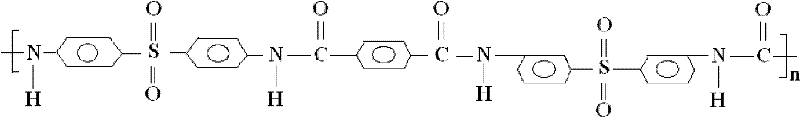

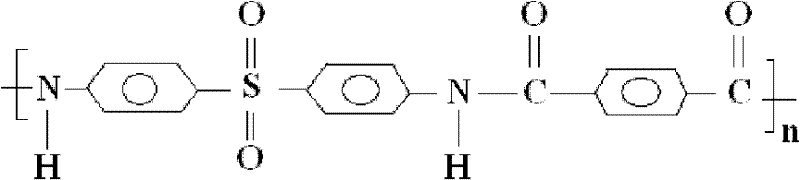

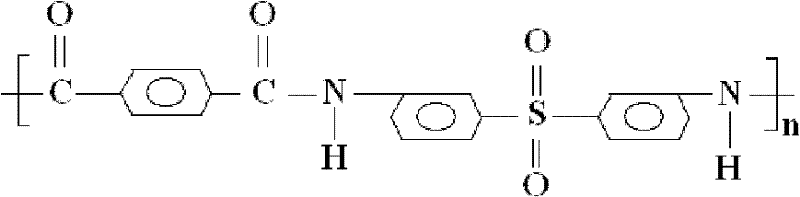

[0025] A powder mica paper, the powder mica paper is composed of fibers and powder mica, the fibers are poly-p-phenyl-sulfone terephthalamide fibers, and the poly-p-phenyl sulfone terephthalamide fibers are evenly distributed on the mica. layer, and the amount of fibers is 2% to 50% of the total mass of the mica paper, such as 2%, 5%, 10%, 15%, 20%, 25%, 30%, 35%, 40%, 45% %, 50%, etc.

[0026] The powder mica is non-calcined muscovite or calcined muscovite, and the mica is pulped by a hydraulic crushing method.

[0027] The fibers have an average length of 0.01-12 mm and an average diameter of 0.1-50 μm.

[0028] A method for manufacturing the powder mica paper, comprising soaking the poly(p-phenylene sulfone terephthalamide) fibers in water and stirring to prepare fiber slurry, and mixing with the powder mica slurry, and the amount of fibers is the total amount of mica paper. 2% to 50% of the mass, stir evenly in the pulp tank, pump it to the paper machine, and make it on ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com