Composite shell of lithium ion battery

A technology for lithium-ion batteries and shells, which is applied to battery pack parts, circuits, electrical components, etc., can solve the problems of ineffective protection of the internal core, easy drop in battery capacity, and low shell strength to achieve convenient heat dissipation channel, light weight, small size effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

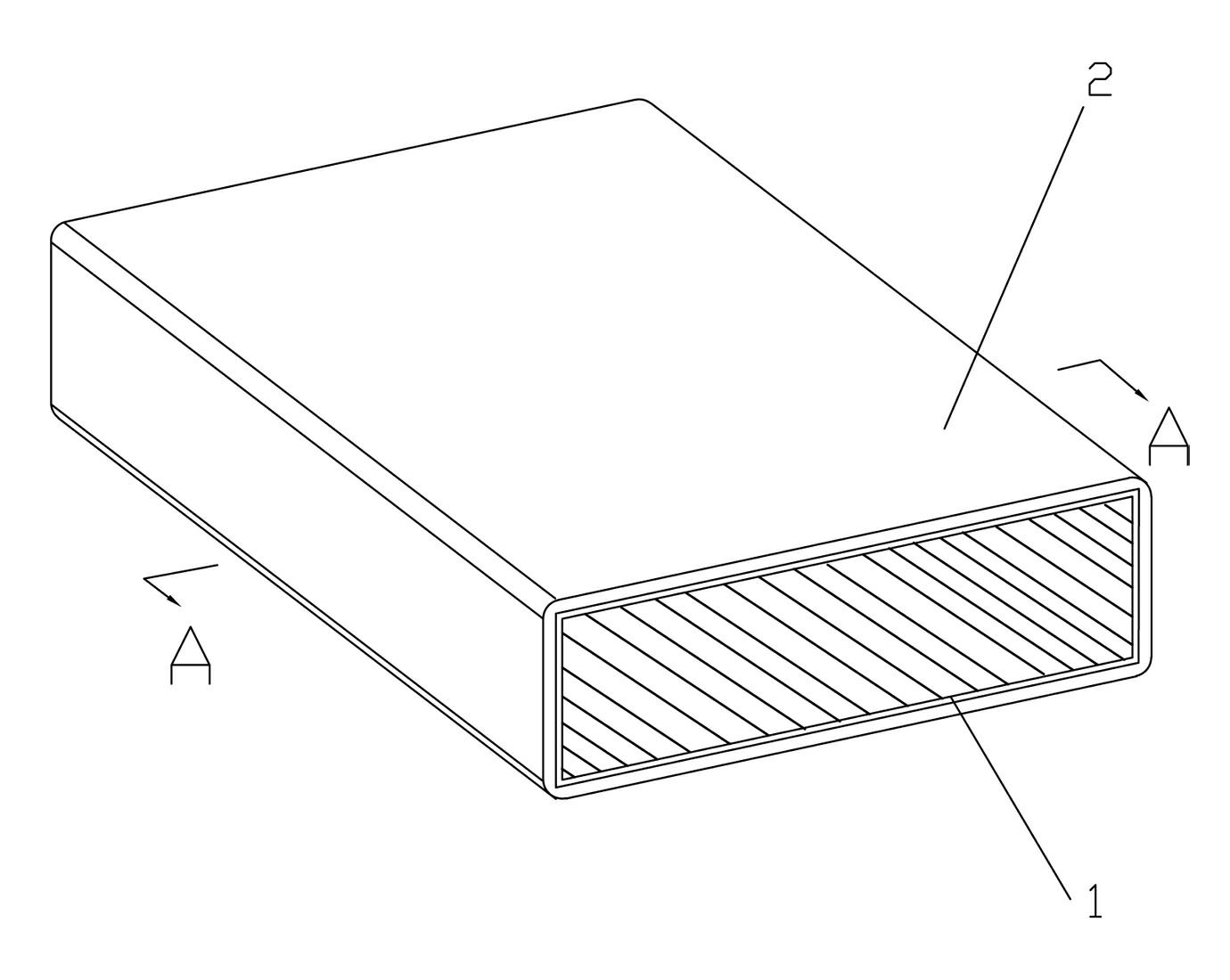

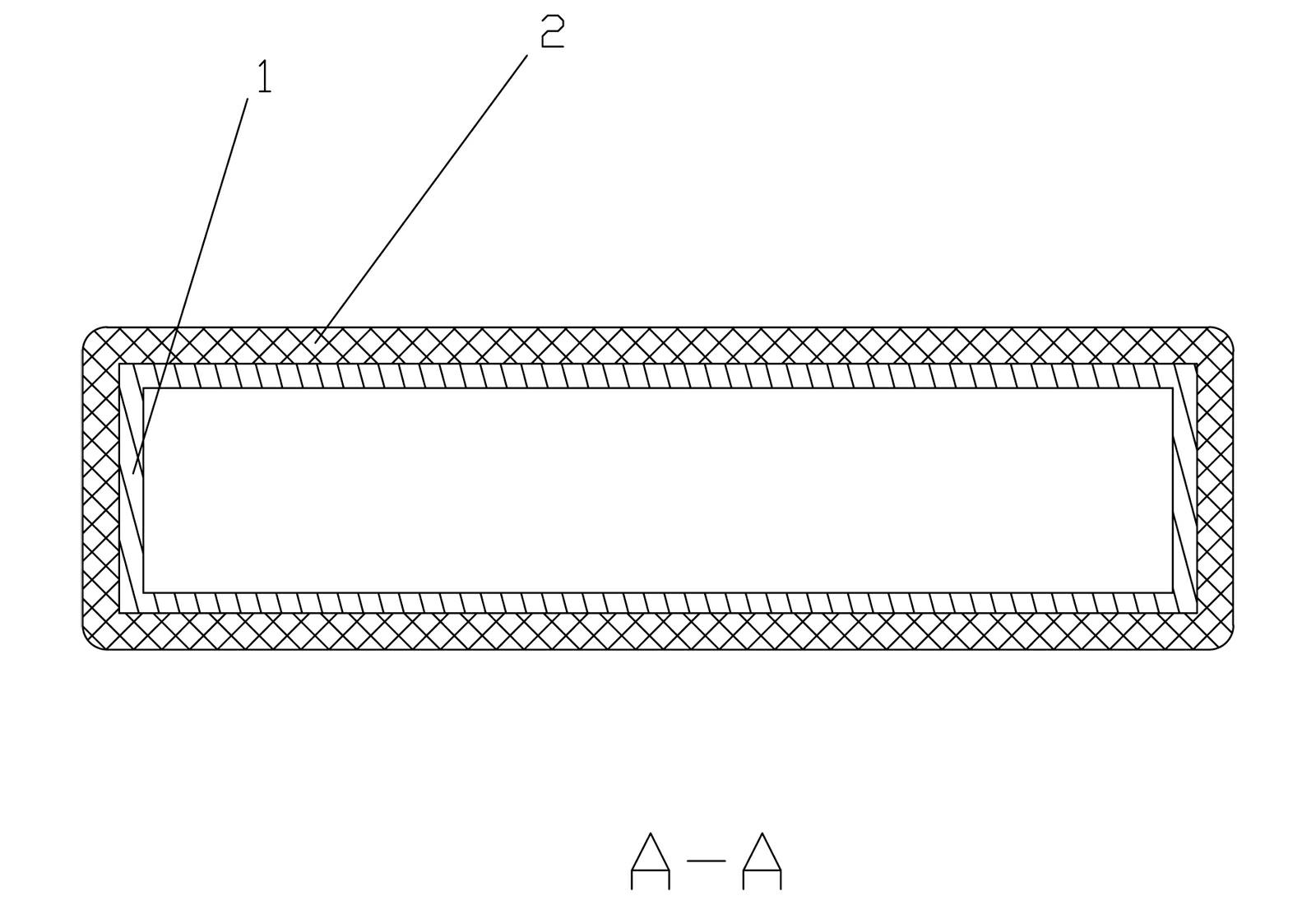

[0019] refer to figure 1 with figure 2 , a composite casing of a lithium-ion battery of the present invention, which includes a metal inner layer 1 and a plastic outer layer 2, the metal inner layer 1 is made of aluminum, aluminum alloy, stainless steel or alloy materials, and its thickness is 0.5~1.5mm, preferably 1mm, used to reduce volume, reduce weight, increase strength, and facilitate welding and sealing; the plastic outer layer 2 is made of PP, ABS, PE or EPDM rubber, and its thickness is 1.5~2.5mm, preferably 2mm, used to increase strength, facilitate combination, ensure insulation, and ensure the practical safety of battery series and parallel connections. In addition, compared with the metal outer layer, the plastic outer layer 2 can conveniently set heat dissipation channels to ensure the air flow inside the battery pack and play a role in heat dissipation. The metal inner layer 1 and the plastic outer layer 2 are compositely connected by thermal compounding, the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com