Reactor for filtering PAHs (polycyclic aromatic hydrocarbons) in composite electrocatalytic oxidation treatment

A technology of a reactor and a reactant is applied in the field of reactors for filtering compound electrocatalytic oxidation to treat PAHs, which can solve problems such as few reports and difficulties, and achieve the effects of small pore size, high porosity, and control of the generation of harmful by-products.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

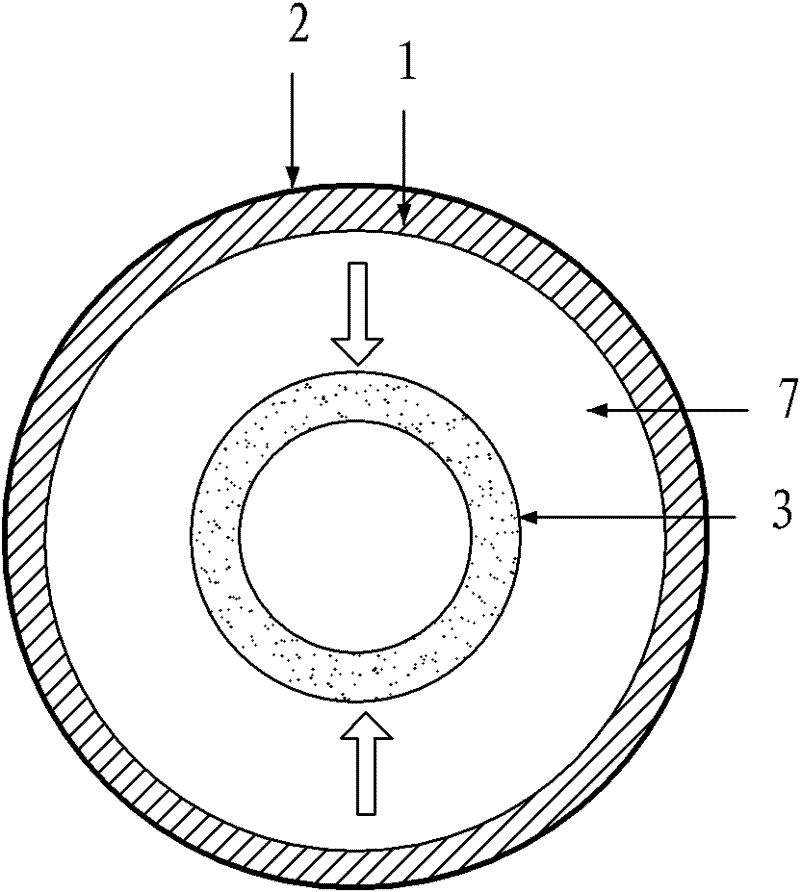

[0029] a kind of like figure 1 and figure 2 The shown cylindrical filtration composite electrocatalytic oxidation reactor for treating PAHs includes a shell 1 (outer cylinder) with a circular cross section and a porous metal reaction body 3 (inner cylinder). The outer cylinder is a quartz glass tube or ceramics, the outer wall of the quartz glass tube or ceramics is wrapped with a metal conductor 2, and the metal conductor 2 is grounded as an external electrode for dielectric barrier discharge. The metal conductor 2 is a metal foil or a metal coating with a thickness of 0.5-1mm, and the material is silver, copper or aluminum. The inner cylinder is connected to an AC high-voltage power supply 6 (10-30kV) as an inner electrode for dielectric barrier discharge. The porous metal reaction body 3 is a porous material with a rigid structure made of spherical or irregular stainless steel powder through press molding and high-temperature sintering, and supports a metal oxide catalys...

Embodiment 2

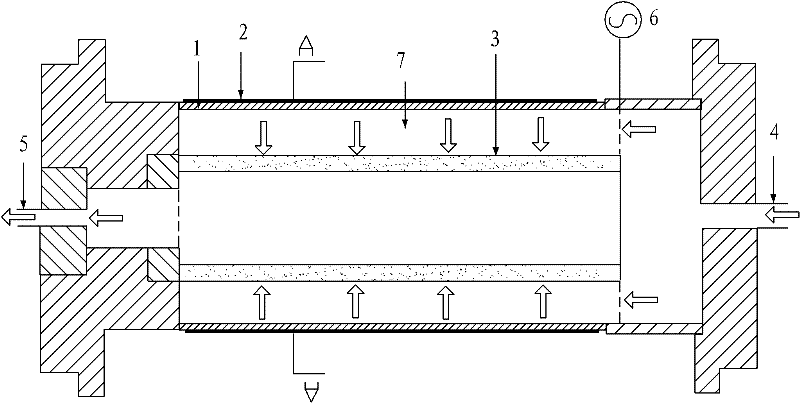

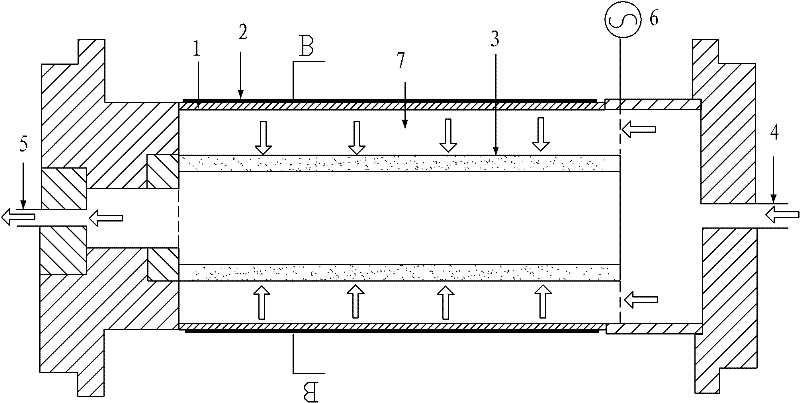

[0031] Such as image 3 and Figure 4 A reactor for treating PAHs with plate-type filtration composite electrocatalytic oxidation includes a housing 1 of quartz glass or ceramics, one end of the housing 1 is an air inlet 4, and the other end is an air outlet 5; the outer layer of the housing 1 The metal conductor 2 is wrapped, and the metal conductor 2 is grounded as the external electrode of the dielectric barrier discharge; the metal conductor 2 is a metal foil or a metal coating with a thickness of 0.5-1mm, and the material is silver, copper or aluminum. There is a porous metal reaction body 3 inside the casing 1, and the porous metal reaction body 3 is connected to an AC high voltage power supply 6 (10-30kV) as an inner electrode for dielectric barrier discharge. The cross-sections of the housing 1 and the porous metal reaction body 3 are both rectangular, and one opposite wall of the reaction body 3 is close to the inner wall of the housing 1 and is isolated by an insula...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com