Cold rolled steel coil wastewater treatment method

A wastewater treatment and cold-rolled steel technology, which is applied in the direction of neutralizing water/sewage treatment, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc., can solve the problems of polluted environment, environmental pollution, destruction, etc., and achieve Improve the precipitation performance, reduce the content of nitrate nitrogen, and benefit the effect of environmental protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

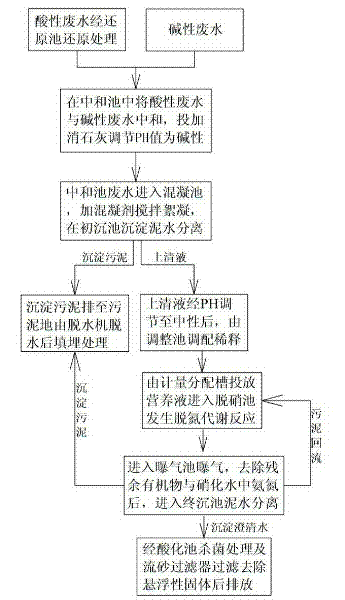

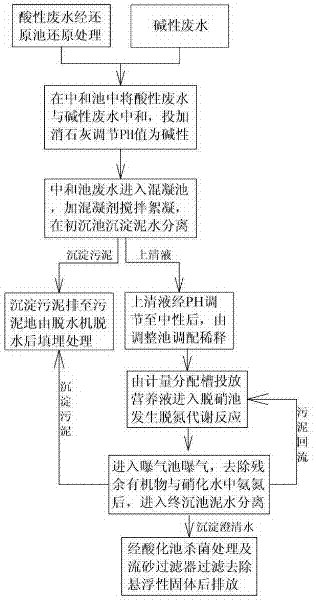

[0018] Below in conjunction with accompanying drawing, the present invention will be further described.

[0019] Such as figure 1 , the cold-rolled steel coil waste water treatment method of the present invention, comprises the steps:

[0020] 1) Acidic wastewater, electrolyte and sulfuric acid wastewater are firstly mixed uniformly through the acid adjustment tank, and then enter the reduction tank. Mix with alkaline wastewater in the neutralization tank, and add slaked lime to adjust the PH value to be alkaline;

[0021] 2) Pump the wastewater from the neutralization tank into the coagulation tank, add coagulant to stir and flocculate, and then carry out mud-water separation in the primary sedimentation tank. The sludge is discharged to the sludge field and is dewatered by a dehydrator before being landfilled;

[0022] 3) The wastewater from the No. 1 intermediate pool is adjusted and diluted by the adjustment pool, and enters the metering and distribution tank to mix and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com