Method for preparing surface-coated yellow fluorescent powder

A technology of yellow fluorescent powder and surface coating, applied in chemical instruments and methods, luminescent materials, electrical components, etc., can solve problems such as uneven light emission of white light-emitting diodes, unstable electrical and chemical properties, poor dispersion of phosphor powder, etc. , to achieve the effect of avoiding the decline of luminous performance, improving the light spot and good uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

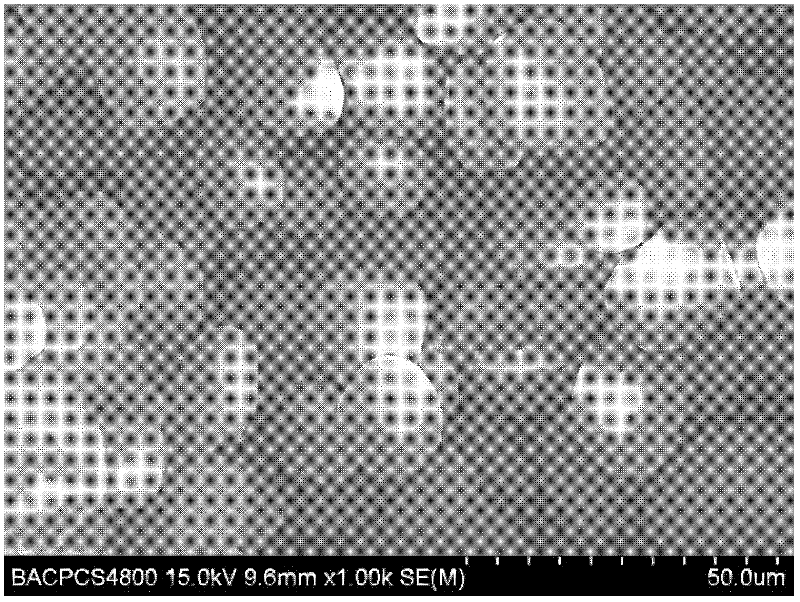

Image

Examples

Embodiment 1

[0022] A preparation method for surface-coated yellow fluorescent powder, comprising the following steps:

[0023] 1) Weigh 0.298mol of Y 2 o 3 , 0.5mol of Al(OH) 3 , 0.001mol of BaCO 3 , CeO as an activator 4 0.001mol, the four compounds were mixed to form a mixture, and then added a flux of 4.6% by weight and ground for 30 minutes to obtain a phosphor precursor; the flux was prepared by YF 3 , AlF 3 、BaF 2 , CeF 3 Composition by mixing; YF in flux 3 :AlF 3 :BaF 2 : CeF 3 The mass ratio is 1:4:1.6:1;

[0024] 2) Place the phosphor precursor in a planetary ball mill for ball milling, mix thoroughly and evenly, and then put it into a roasting container, put double-layer graphite surface coating blocks inside and outside the container, and put them together at high temperature Heating in the furnace, keeping the temperature at 1000°C for 1 hour, then raising the temperature to 1450°C for 6 hours, and cooling in air after the roasting is completed, to obtain the roas...

Embodiment 2

[0028] A preparation method for surface-coated yellow fluorescent powder, comprising the following steps:

[0029] 1) Weigh 0.295mol of Y 2 o 3 , 0.5mol of Al(OH) 3 , 0.002mol of BaCO 3 , CeO as an activator 4 0.003mol, the four compounds were mixed to form a mixture, and then 8% of the mass of the mixture was added as a flux and ground for 30 minutes to obtain a phosphor precursor; the flux was supplied by YF 3 , AlF 3 、BaF 2 , CeF 3 Composition by mixing; YF in flux 3 :AlF 3 :BaF 2 : CeF 3 The mass ratio is 1:5:2:1.2;

[0030] 2) Place the phosphor powder precursor in a planetary ball mill for ball milling, mix well and evenly, then put it into a roasting container, put carbon powder inside and outside the container, and put it into a high-temperature furnace for heating, 800 ℃ for 1.5h, then heated up to 1300°C and roasted for 10h, after the roasting was completed, cooled in the air to obtain the roasted product;

[0031] 3) Break the roasted product after coo...

Embodiment 3

[0034] The preparation method of yellow fluorescent powder comprises the following steps:

[0035] 1) Weigh 0.29mol of Y 2 o 3 , 0.5mol of Al(OH) 3 , 0.004mol of BaCO 3 , CeO as an activator 4 0.006mol, the four compounds are mixed to form a mixture, and then 1% of the mass of the mixture is added as a flux and ground for 30 minutes to obtain a phosphor precursor; the flux is provided by YF 3 , AlF 3 、BaF 2 , CeF 3 Composition by mixing; YF in flux 3:AlF 3 :BaF 2 : CeF 3 The mass ratio is 1:6:2.2:1.4;

[0036] 2) Place the phosphor precursor in a planetary ball mill for ball milling, mix thoroughly and evenly, then put it into a roasting container, put carbon powder inside and outside the container, and put them together in a high-temperature furnace for heating, 900 ℃ for 1.2h, then heated up to 1550℃ and roasted for 10h, after the roasting was completed, cooled in the air to obtain the roasted product;

[0037] 3) Break the roasted product after cooling, collec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com