Method for co-depositing Al-Mn alloy plating layer in ionic liquid system

A technology of ionic liquid and alloy coating, applied in the field of electroplating, can solve the problems of sensitivity, limited application, unstable properties of ionic liquid, etc., and achieve the effects of low heat energy, reduced defective rate, and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

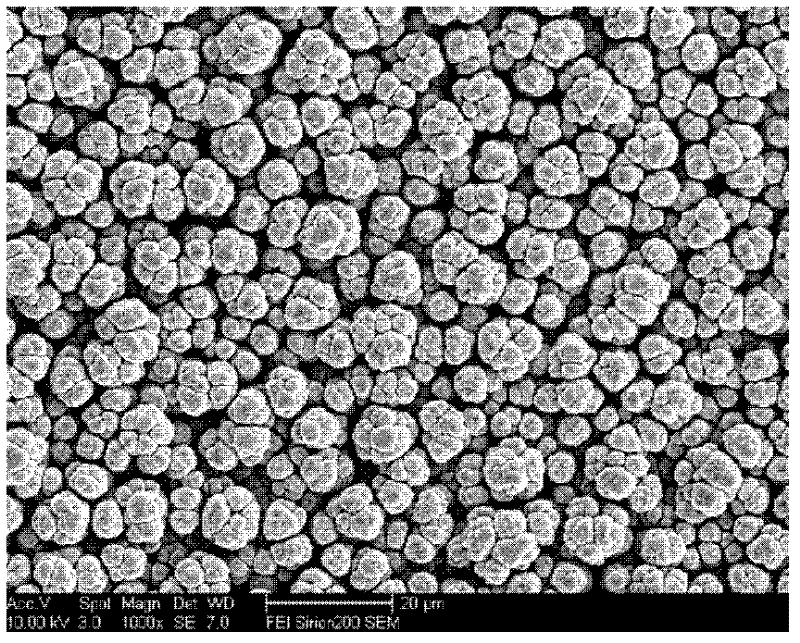

Embodiment 1

[0023] Take Nd 2 (SO 4 ) 3 +MnSO 4 +Al 2 o 3 +[EMIM]HSO 4 It is an electrolyte system, with Fe plate as the cathode, 99wt% aluminum plate as the anode, the electrolysis temperature is controlled at 100°C, the pole distance is 2cm, and the current density is controlled at 60mA / cm 2 , The tank voltage is controlled at 2V. First add 114.6gAl 2 o 3 and 28.6L [EMIM]HSO 4 , then add 2.64gMnSO 4 and 0.265gNd 2 (SO 4 ) 3 After dissolving for 10 minutes, insert the cathode and anode for electroplating, and the electroplating time is 60 minutes.

Embodiment 2

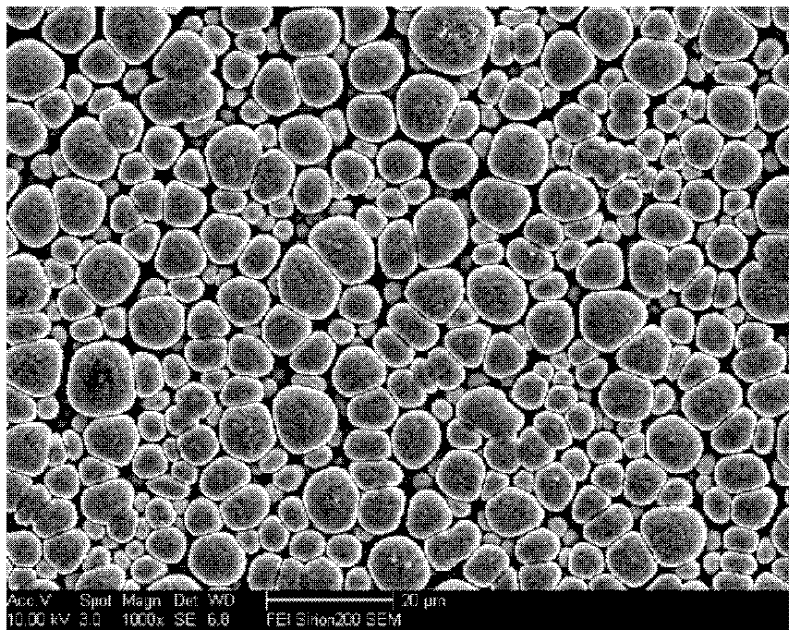

[0025] to Ce 2 (SO 4 ) 3 +MnSO 4 +Al 2 o 3 +[EMIM]HSO 4 It is an electrolyte system, with steel plate as the cathode and 99wt% aluminum plate as the anode, the electrolysis temperature is controlled at 100°C, the pole distance is 2cm, and the current density is controlled at 60mA / cm 2 , The tank voltage is controlled at 2V. First add 114.6g Al 2 o 3 and 28.6L [EMIM]HSO 4 , then add 2.64gMnSO 4 and 0.262gCe 2 (SO 4 ) 3 After dissolving for 10 minutes, insert the cathode and anode for electroplating, and the electroplating time is 60 minutes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com