Coal integrally-gasified smoke reheating combined-cycle power system

A technology of flue gas reheating and integral gasification, which is applied in the direction of combined combustion mitigation, machine/engine, steam engine device, etc., can solve the problems of flue gas reheating, and achieve the effect of net thermal efficiency improvement, low cost and high energy efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

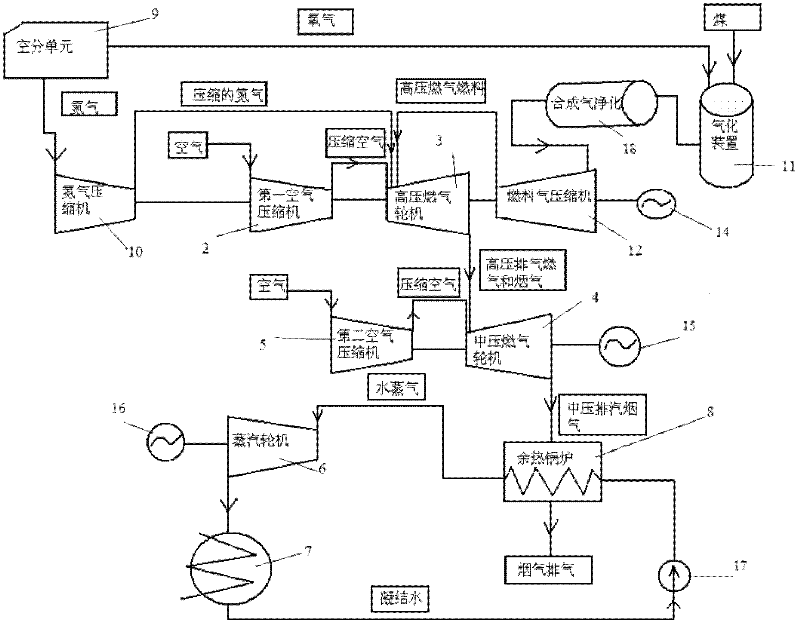

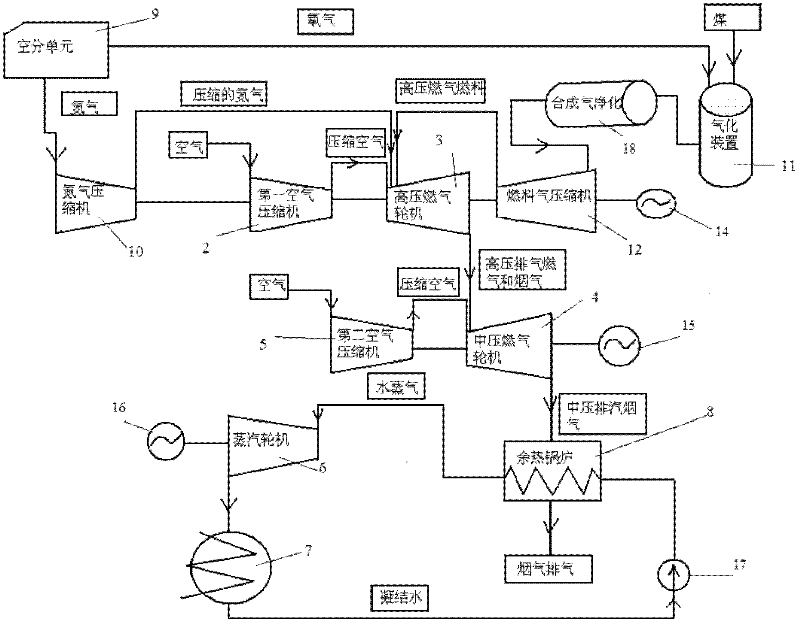

[0014] A coal integral gasification flue gas reheating combined cycle power system, such as attached figure 1 As shown, after the nitrogen compressor 10 compresses the nitrogen produced by the air separation unit, it enters the high-pressure gas turbine 3 together with the high-pressure compressed air produced by the first air compressor 2 and the high-pressure fuel gas produced by the fuel gas compressor 12, and the high-pressure gas turbine 3 The outlet flue gas (including partially incompletely burned fuel gas) enters the medium-pressure gas turbine 4 together with the compressed air generated by the second air compressor 5, and the fuel gas is completely combusted in the medium-pressure gas turbine 4, and the flue gas at the outlet of the medium-pressure gas turbine 4 After entering the waste heat boiler 8, the flue gas releases heat in the waste heat boiler 8 and is discharged into the atmosphere through the chimney. The steam generated by the waste heat boiler 8 enters th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com