Nitride semiconductor element and method for manufacturing same

A technology of nitride semiconductors and manufacturing methods, applied in semiconductor/solid-state device manufacturing, semiconductor devices, electrical components, etc., can solve the problems of Mg diffusion, reduced luminous efficiency, and increased man-hours, and achieve reduced impurity diffusion and high-efficiency luminescence , the effect of low forward voltage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

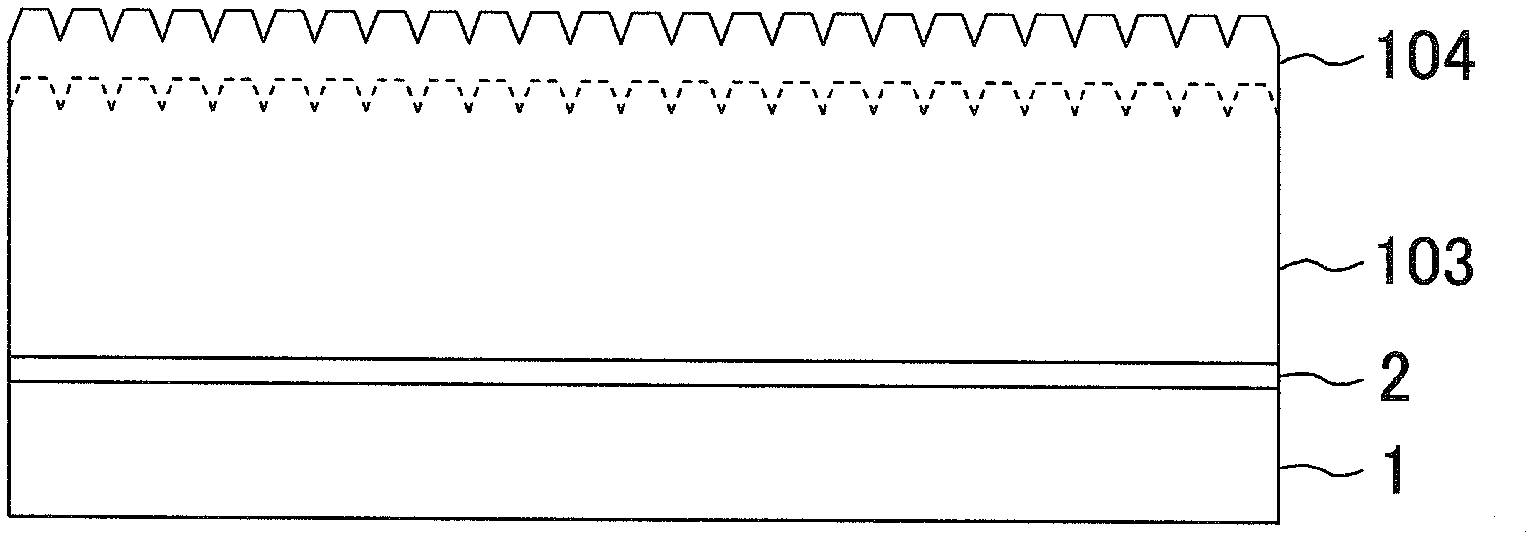

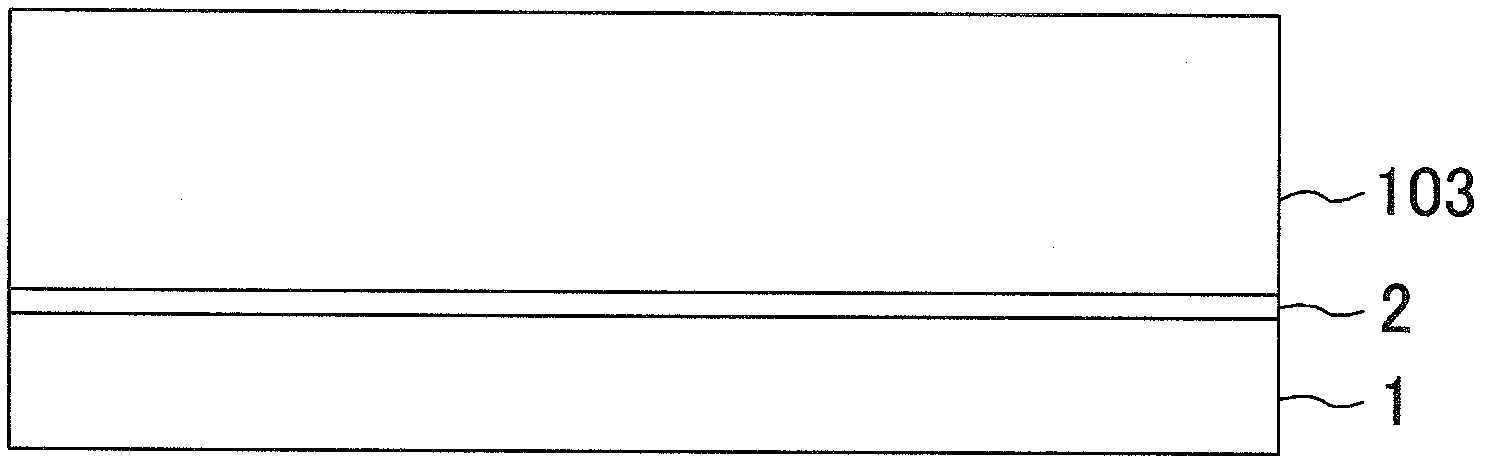

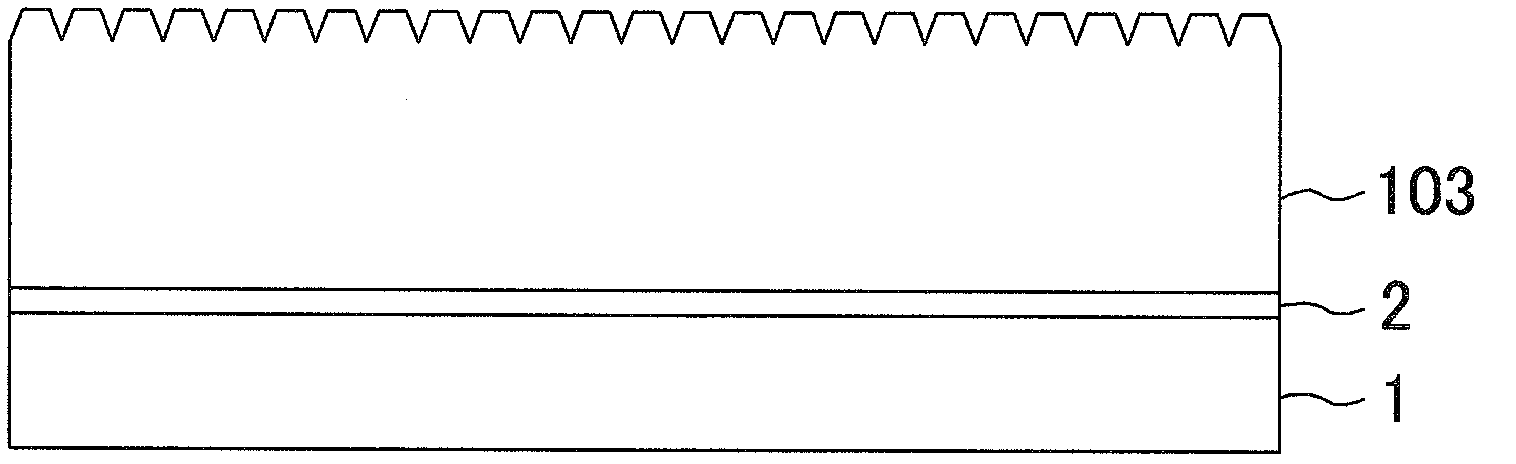

[0065] The first embodiment of the present invention will be described. figure 1 It is a cross-sectional view of the semiconductor laminated structure according to the first embodiment of the present invention.

[0066] In the semiconductor laminated structure of the first embodiment, on the Si substrate 1 with the (111) plane as the main surface, the buffer layer 2 made of AlN and the non-doped GaN are sequentially formed with the C plane (0001) plane as the growth plane. In the first nitride semiconductor layer 103 formed, a second nitride semiconductor layer 104 made of p-type GaN is formed on the first nitride semiconductor layer.

[0067] Here, the first nitride semiconductor layer 103 has unevenness, and the second nitride semiconductor layer 104 is formed in contact with the unevenness. At least a part of the uneven side surface of the first nitride semiconductor layer 103 is composed of a nitrogen polar surface, for example, (1-101). Carbon (C) is added to the second nitri...

Embodiment approach 2

[0083] Hereinafter, the second embodiment of the present invention will be described. image 3 It is a cross-sectional view of the LED according to the second embodiment of the present invention.

[0084] In the nitride semiconductor light-emitting element of the second embodiment, on the Si substrate 1 with the (111) plane as the main surface, the buffer layer 2 made of AlN and the n-type An n-type nitride semiconductor layer 3 made of GaN, a light emitting layer 4, an overflow suppression layer made of p-type AlGaN (hereinafter referred to as OFS layer) 5, and a first p-type nitride semiconductor layer made of p-type GaN 6. A second p-type nitride semiconductor layer 7 made of p-type GaN is formed on the first p-type nitride semiconductor layer 6, and the light-emitting layer 4, OFS layer 5, first p-type nitride semiconductor layer 6, A negative electrode 8 is formed on a region where a part of the second p-type nitride semiconductor layer 7 is exposed to the n-type nitride sem...

Embodiment approach 3

[0117] The third embodiment will be described. In the second embodiment, an LED was described, but the p-type nitride semiconductor layer of the present invention can also be applied to LD. Figure 8 It is a cross-sectional view of a laser diode (hereinafter referred to as LD) according to Embodiment 3 of the present invention.

[0118] In the nitride semiconductor light-emitting element of the third embodiment, on a substrate 201 made of n-type GaN with the (0001) plane as the main surface, the n-type Al a Ga 1-a N (0≤aa Ga 1-a The first p-type nitride semiconductor layer 6 composed of N (0a Ga 1-a The second p-type nitride semiconductor layer 7 composed of N (0b Ga 1-b A multiple quantum well structure formed by a well layer composed of N (0a Ga 1-a A current constriction layer 214 composed of N (0≤a<1). As a result, current can be selectively flowed through the current opening 215, and the light-emitting region can be drawn.

[0119] Here, the first p-type nitride semiconductor ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com