Method for separating and preparing instant tea by use of multilayer membranes

A technology of instant tea and multi-layer film, applied in the directions of tea, application, tea extraction, etc., can solve problems such as damage to beneficial components of tea, inability to effectively remove impurities and residues of tea concentrate, to ensure consistency and overcome solvent residues and aroma loss, removal of pesticide residues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

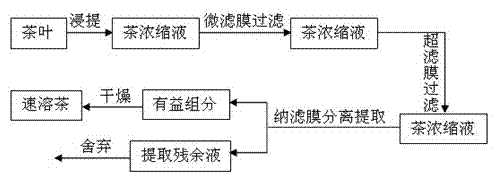

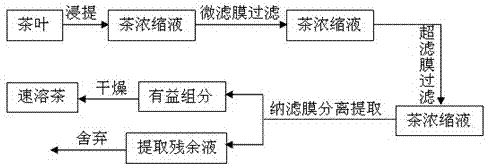

Method used

Image

Examples

Embodiment 1

[0028] (1) Select 1 kg of Pu'er tea, soak it in 20 L of cold water at 10°C for two hours, and obtain a tea concentrate after preliminary clarification.

[0029] (2) Filter with a microfiltration membrane with a pore size of 0.1 μm to obtain the clarified liquid of the tea concentrate. In this embodiment, in order to increase the speed, the pressure of 0.2MPa can be increased during filtration.

[0030] (3) Select an ultrafiltration membrane with a molecular weight of 100,000 for the second filtration to obtain an ultrafiltrate of the tea concentrate. The main purpose of this step is to further improve the clarity of the tea concentrate, while removing macromolecular impurities, including colloid, starch, fiber, protein, etc. In order to speed up the filtration, the pressure of 0.2MPa can be increased during filtration. Because in this method, the purpose of ultrafiltration is to remove macromolecular impurities and retain beneficial components as much as possible, so a highe...

Embodiment 2

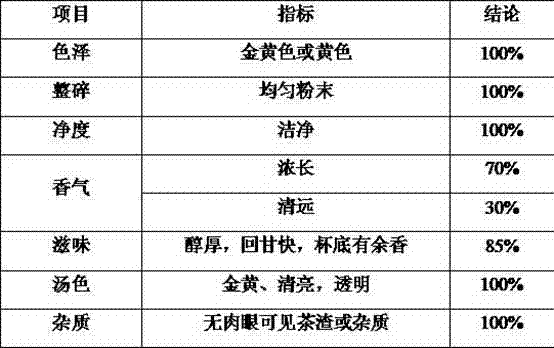

[0036] Sensory evaluation results

[0037] Select 100 people at random, drink the Dahongpao instant tea that this patent application method makes, after calculating the average, draw the following table 1:

[0038]

Embodiment 3

[0040] The green tea instant tea physical and chemical index that this patent application method makes is as shown in table 2:

[0041] Table 2

[0042]

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com