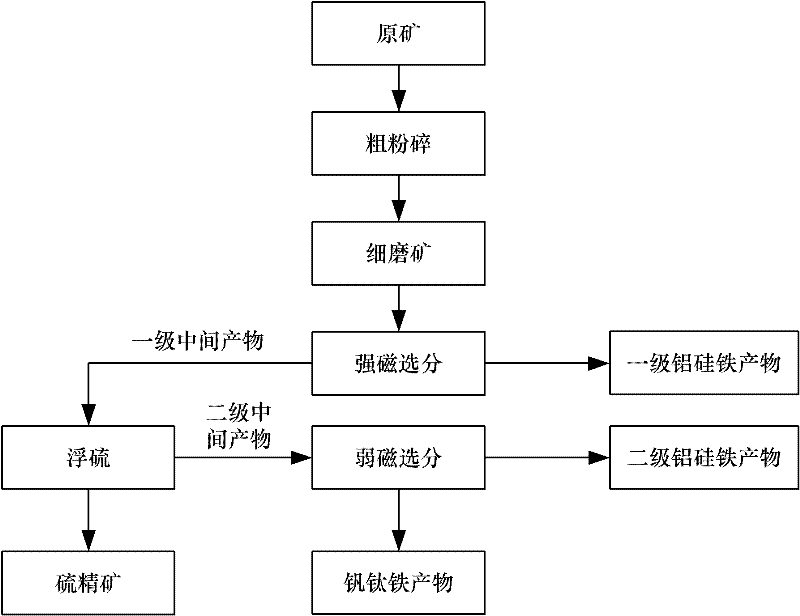

Method for separating ferro-silicon-aluminum products and vanadium-titanium-iron products from aluminum-vanadium-titanium-iron-silicon composite paragenetic minerals by adopting gradient magnetic separation process

A gradient magnetic separation and symbiotic ore technology, applied in chemical instruments and methods, solid separation, wet separation, etc., can solve the problems of low grade, difficult ore dressing means, and obtain qualified iron concentrate and titanium concentrate, etc., to achieve Reduce consumption, save production cost, and shorten the process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0070] Step 1: Coarse Grinding

[0071] The aluminum-vanadium-titanium-iron-silicon composite symbiotic ore is crushed by mechanical crushing (PET-60×100 jaw crusher) to obtain a coarsely crushed ore with a particle size of less than 400 mesh;

[0072] The main component of the raw ore (gross ore) used in embodiment 1 is (mass percentage):

[0073] TF

MgO

TiO 2

MnO

FeO

SiO 2

Fe 2 o 3

CaO

19.96

4.04

7.30

0.25

8.00

33.51

19.40

7.41

Al 2 o 3

V 2 o 5

K 2 o

MFe

Na 2 o

P

S

sc

13.15

0.18

0.82

0.17

1.59

0.15

0.56

0.0049

co

Ni

Cu

Burn down

Cr 2 o 3

0.011

0.0055

<0.005

2.80

<0.10

[0074] Step 2: Fine Grinding

[0075] The coarse crushed ore is crushed with a grinder (XMQ-240×90 ball mill) to obtain a pulp with a ...

Embodiment 2

[0101] Step 1: Coarse Grinding

[0102] The aluminum-vanadium-titanium-iron-silicon composite symbiotic ore is crushed by mechanical crushing to obtain a coarsely crushed ore with a particle size of 200 mesh;

[0103] The main component of the raw ore (gross ore) used in embodiment 2 is (mass percentage):

[0104] TF

MgO

TiO 2

MnO

FeO

SiO 2

Fe 2 o 3

CaO

19.96

4.04

7.30

0.25

8.00

33.51

19.40

7.41

al 2 o 3

V 2 o 5

K 2 o

MFe

Na 2 o

P

S

sc

13.15

0.18

0.82

0.17

1.59

0.15

0.56

0.0049

co

Ni

Cu

Burn down

Cr 2 o 3

0.011

0.0055

<0.005

2.80

<0.10

[0105] Step 2: Fine Grinding

[0106] The coarse crushed ore is crushed with a grinder to obtain a pulp with a particle size of less than 200 mesh;

[0107] The mass ...

Embodiment 3

[0123] Step 1: Coarse Grinding

[0124] The aluminum-vanadium-titanium-iron-silicon composite symbiotic ore is crushed by mechanical crushing to obtain a coarsely crushed ore with a particle size of 300 mesh;

[0125] The main component of the raw ore (gross ore) used in embodiment 3 is (mass percentage):

[0126] TF

MgO

TiO 2

MnO

FeO

SiO 2

Fe 2 o 3

CaO

19.96

4.04

7.30

0.25

8.00

33.51

19.40

7.41

Al 2 o 3

V 2 o 5

K 2 o

MFe

Na 2 o

P

S

sc

13.15

0.18

0.82

0.17

1.59

0.15

0.56

0.0049

co

Ni

Cu

Burn down

Cr 2 o 3

0.011

0.0055

<0.005

2.80

<0.10

[0127] Step 2: Fine Grinding

[0128]The coarse crushed ore is crushed with a grinder to obtain a pulp with a particle size of less than 200 mesh;

[0129] The mass per...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com