Dai flavor beef instant jerky and processing method thereof

A processing method and beef technology, which is applied in the field of Dai beef instant dried beef and its processing, can solve the problems of hard taste, high hardness, and easy deterioration, and achieve the effects of avoiding the loss of nutrients, being convenient for travel and eating, and having stable quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

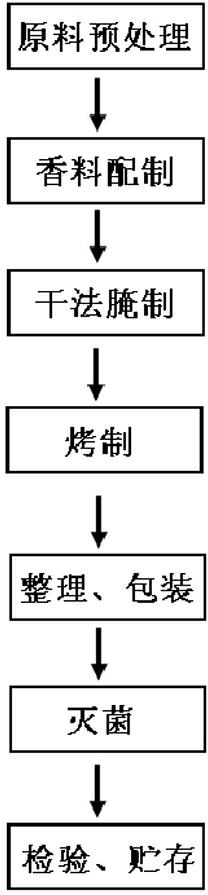

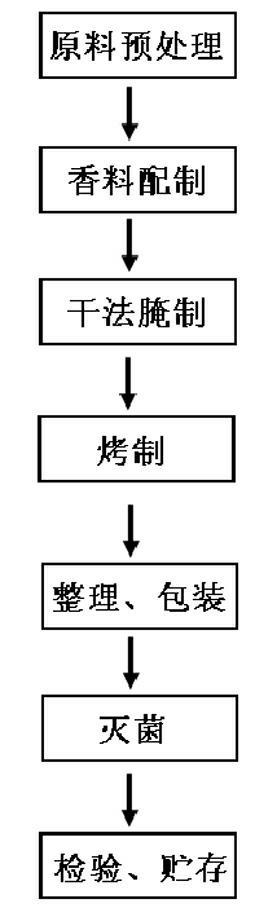

Method used

Image

Examples

Embodiment 1

[0034] Select 10kg of lean beef that has passed the sanitation and quarantine, remove the tendons and fat, and cut into strips of 1.0cm×1.0cm×30cm; according to the weight of beef, 0.1% lemongrass, 0.03% pepper, and 0.005% pepper , 0.5% ginger, 0.1% star anise, 0.3% cinnamon, and 0.1% cumin are made into powder respectively, and then mixed with 1.0% refined salt and 0.3% monosodium glutamate for later use; put the beef and spices into a tumbler and knead them Roll and knead at 4°C for 8 minutes, put the rolled beef strips into a stainless steel marinating tank layer by layer, and marinate at 4°C for 5 hours; On the rod, the distance between strips is 4~6cm, dehydrated and dried by charcoal fire at 55°C for 10h; then raise the temperature to 105°C and bake for 1h until the beef is fully cooked; cut the grilled beef strips according to the specifications, and arrange them according to the packaging Specification weighing, vacuum packaging, microwave sterilization at 90°C for 3 m...

Embodiment 2

[0036] Select 10kg of lean beef that has passed the health quarantine, remove the tendons and fat, and cut into strips of 2.0cm×2.0cm×40cm; according to the weight ratio of beef, 0.3% lemongrass, 0.06% pepper, 0.015% pepper, Ginger 1.5%, star anise 0.3%, cinnamon 0.5%, cumin 0.3%, respectively made into powder, and then mixed with refined salt 1.5%, monosodium glutamate 0.4% for later use; put the beef and spices into the tumbler and knead, Tumble and knead for 10 minutes at 6°C, put the rolled beef strips into a stainless steel marinating tank layer by layer, and marinate for 6 hours at 7°C; first hook the marinated strips of meat and evenly hang them on the hanging rods in the grill Above, the distance between the strips is 4~6cm, dehydrated and dried with charcoal fire at 65°C for 12h; then raise the temperature to 115°C and bake for 2h until the beef is fully cooked; cut the grilled beef strips according to the specifications, and arrange them according to the packaging spe...

Embodiment 3

[0038]Select 10kg of lean beef that has passed the health and quarantine inspection, remove tendons and fat, and cut into strips of 3.0cm×3.0cm×35cm; according to the weight ratio of beef, 0.2% lemongrass, 0.04% pepper, 0.01% pepper, Ginger 1.0%, star anise 0.2%, cinnamon 0.4%, cumin 0.2%, respectively, ground into powder, then mixed with 1.8% refined salt, 0.5% monosodium glutamate for later use; Tumble and knead for 12 minutes at 8°C, put the rolled beef strips into a stainless steel marinating tank layer by layer, and marinate at 6°C for 8 hours; first hook the marinated meat strips and evenly hang them on the hanging rods in the grilling room Above, the distance between strips is 4~6cm, dehydration and drying with charcoal fire at 70°C for 11 hours; then raise the temperature to 110°C and bake for 1.5 hours until the beef is fully cooked; cut the grilled beef strips according to the specifications and arrange them according to the specifications. Specification weighing, va...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com