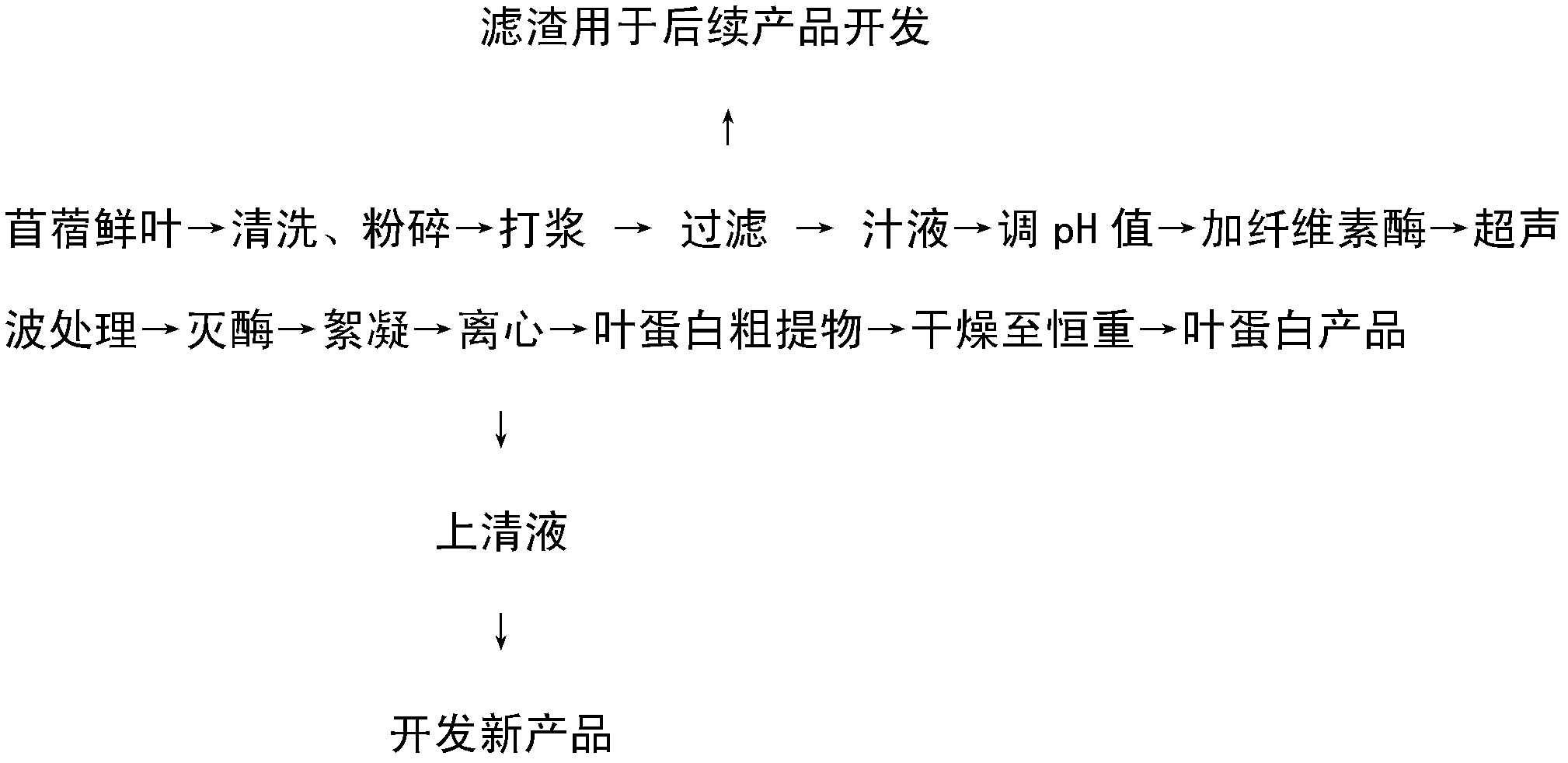

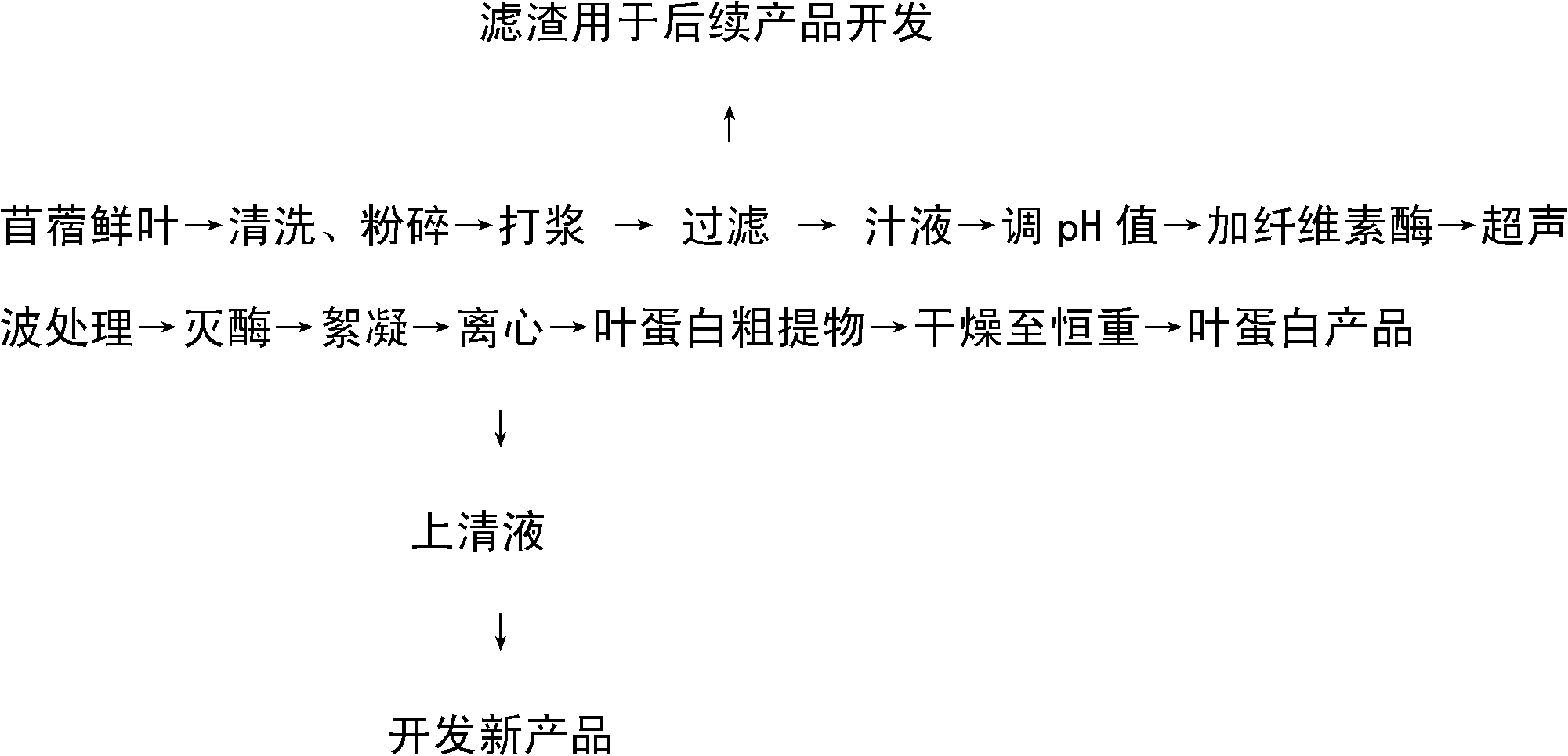

Method for extracting alfalfa leaf protein by ultrasonic-assisted enzyme process

The technology of alfalfa leaf protein and ultrasonic wave is applied in the field of vegetable protein, which can solve the problems of waste of resources and lack of vegetable protein resources, and achieve the effects of low cost, wide source of raw materials and high extraction rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] (1) Processing raw material: adopt fresh alfalfa at the early flowering stage, and get its plant leaves as processing raw material, and described alfalfa at the early flowering stage includes fresh alfalfa in the second crop or the third crop at the early flowering stage after mowing. After the alfalfa is harvested, it should be processed as soon as possible. If it needs to be stored for a short time, it should be sealed in a fresh-keeping bag and refrigerated at about 5°C, so as not to reduce the yield and quality of alfalfa leaf protein due to the respiration of the leaf itself and microbial contamination. .

[0030] (2) Cleaning and crushing: wash with tap water for 3 times, and remove withered, yellowed, rotten and pest-infested leaves in the raw material of alfalfa leaves during the cleaning process. Cut the washed leaves into 1cm pieces;

[0031] (3) Beating and juicing: add water according to the weight ratio of alfalfa leaves: water = 1:2, put it into a tissue ...

Embodiment 2

[0038] (1) processing raw material: with embodiment 1

[0039] (2) cleaning, pulverizing: with embodiment 1

[0040] (3) beating, squeezing the juice: with embodiment 1

[0041] (4) ultrasonic-assisted enzymolysis: the enzyme that extracts leaf protein adopts cellulase, and cellulase is added in the alfalfa juice that (3) obtains, and enzyme amount is that every 100 milliliters of juices use 3 grams of cellulase, use The pH of the malic acid-adjusted juice is 4.5. After fully stirring and mixing, put it into an ultrasonic extractor for ultrasonic extraction. The ultrasonic extraction conditions are: ultrasonic power 200W, frequency 30kHz, temperature 55°C, ultrasonic continuous action, time 30min, to obtain the extract;

[0042] The above extract contains cellulase with an enzyme activity of 8000U / g, and the unit of cellulase activity is defined as the concentration of 4 mg / mL sodium carboxymethyl cellulose per minute at 37 ° C and a pH value of 5.5. The amount of enzyme nee...

Embodiment 3

[0047] (1) processing raw material: with embodiment 1

[0048] (2) cleaning, pulverizing: with embodiment 1

[0049] (3) beating, squeezing the juice: with embodiment 1

[0050] (4) Ultrasonic-assisted enzymolysis: the enzyme that extracts leaf protein adopts cellulase, and cellulase is added in the alfalfa juice that (3) obtains, and enzyme amount is that every 100 milliliters of described juices use 3.5 grams of cellulase, use The pH of the tartaric acid-adjusted juice is 5, fully stirred and mixed, and then put into an ultrasonic extractor for ultrasonic extraction. The ultrasonic extraction conditions are: ultrasonic power 250W, frequency 30kHz, temperature 50°C, ultrasonic continuous action, time 40min, to obtain the extract;

[0051] The above extract contains cellulase with an enzyme activity of 8000U / g, and the unit of cellulase activity is defined as the concentration of 4 mg / mL sodium carboxymethyl cellulose per minute at 37 ° C and a pH value of 5.5. The amount of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com