Double-component silicone structural sealant

A sealant, two-component technology, applied in the field of sealant, to achieve good aging resistance, good adhesion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

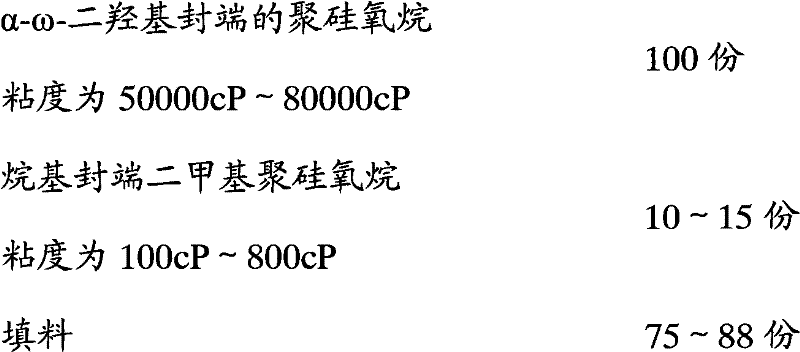

Method used

Image

Examples

Embodiment 1

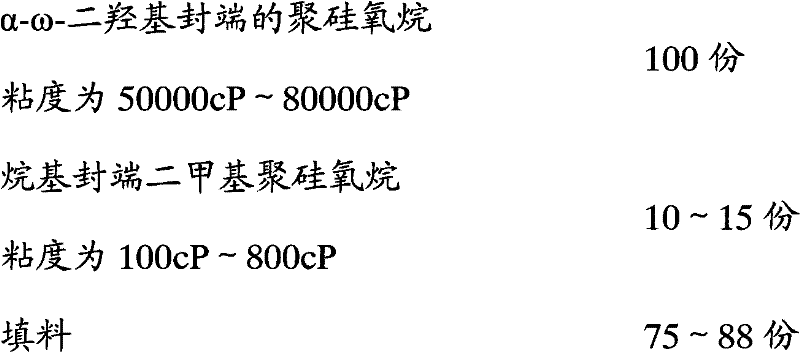

[0028] Component A: 100 parts of α-ω-dihydroxy-terminated polysiloxane with a viscosity of 80,000 cp, 15 parts of alkyl-terminated dimethyl polysiloxane with a viscosity of 500 cp, and 5 parts of hydrophobic fumed silica, Add 70 parts of nano-active calcium carbonate to the planetary mixer and mix well.

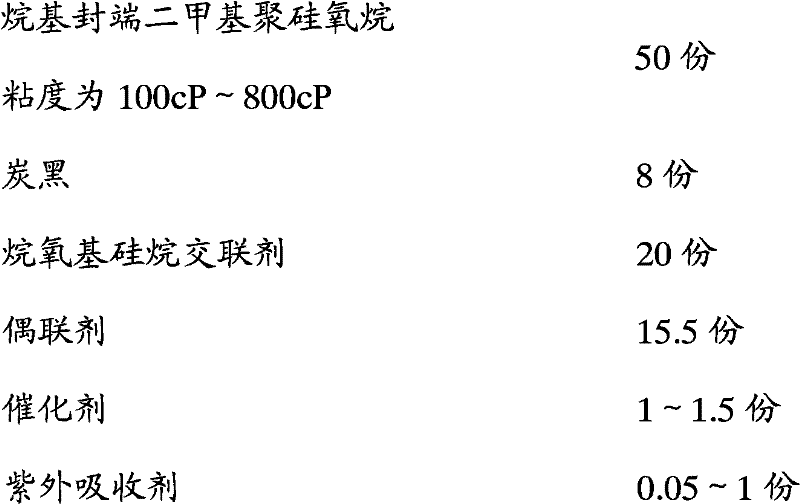

[0029] B component: 50 parts of alkyl-terminated dimethyl polysiloxane with a viscosity of 500cp, 8 parts of carbon black, 10 parts of ethyl orthosilicate, 10 parts of polymethyltriethoxysilane, γ- 15 parts of aminopropyltriethoxysilane, 0.5 parts of ethyl diacetoacetate diisopropyl titanate, 1 part of dibutyl tin dilaurate, and 0.05 parts of ultraviolet absorber are added to the planetary mixer at negative pressure -0.08MPa Stir evenly.

[0030] At room temperature, the components A and B are mixed according to the weight ratio A:B=12:1 to obtain a two-component silicone structural sealant.

Embodiment 2

[0032] A component: 100 parts of α-ω-dihydroxy-terminated polysiloxane with a viscosity of 50000cp, 10 parts of alkyl-terminated dimethylpolysiloxane with a viscosity of 800cp, 8 parts of hydrophobic fumed silica, Add 80 parts of nano-active calcium carbonate to the planetary mixer and mix well.

[0033] B component: 50 parts of alkyl-terminated dimethyl polysiloxane with a viscosity of 800cp, 8 parts of carbon black, 10 parts of propyl orthosilicate, 10 parts of polymethyltriethoxysilane, γ- (2.3-Glycidoxy) 15 parts of propyltrimethoxysilane, 0.5 parts of ethyl diacetoacetate diisopropyl titanate, 1.5 parts of dibutyl tin dilaurate, 0.1 part of UV absorber added to the planetary mixer Stir evenly under negative pressure -0.08MPa.

[0034] At room temperature, the components A and B are mixed according to the weight ratio A:B=12:1 to obtain a two-component silicone structural sealant.

Embodiment 3

[0036] Component A: 100 parts of α-ω-dihydroxy-terminated polysiloxane with a viscosity of 80,000 cp, 10 parts of alkyl-terminated dimethyl polysiloxane with a viscosity of 100 cp, and 5 parts of hydrophobic fumed silica, Add 72 parts of nano-active calcium carbonate to the planetary mixer and stir evenly.

[0037] B component: 50 parts of alkyl-terminated dimethyl polysiloxane with a viscosity of 100 cp, 10 parts of carbon black, 10 parts of methyl trimethoxysilane, 10 parts of polymethyl triethoxy silane, N- Add 15 parts of β-(aminoethyl)-γ-aminopropyl trimethoxysilane, 0.5 parts of ethyl diacetoacetate diisopropyl titanate, 1.5 parts of dibutyl tin dilaurate, and 0.1 part of ultraviolet absorber. Stir evenly in the planetary mixer under negative pressure -0.08MPa.

[0038] At room temperature, the components A and B are mixed according to the weight ratio A:B=12:1 to obtain a two-component silicone structural sealant.

[0039] Through the verification test, it is known that the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com