Manufacture process of germinated brown rice

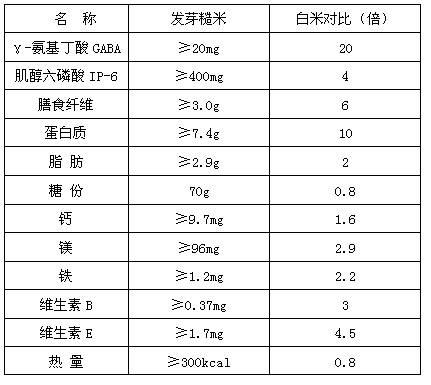

A production process and a technology for germinated brown rice, applied in the field of production technology of germinated brown rice, can solve the problems of difficult control of germination technology, large investment, and high requirements for germination facilities and equipment, and achieve significant economic and social benefits, high nutritional value, The effect of increasing the germination rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The production process of germinated brown rice adopted in the present invention is as follows:

[0016] 1. Wet method

[0017] The brown rice uses the germination bed (the germination bed has three functions of cleaning, soaking, and germination) for wet cleaning and selection (the brown rice is rolled and cleaned in the germination bed) (selected 1.2mm (sieve size), the focus is on removing the adhesion outside The layer of dust, sand, gravel, broken rice, etc., rinse with water after cleaning. t (soaking) = 2 hours, t (breaking water) = 2 hours; (soaking refers to filling the germination bed with water and soaking the brown rice. Water breaks Drain the water in the germination bed to make the brown rice contact with air)

[0018] 2. Soak

[0019] After rinsing, soak the brown rice in water at 30°C±1°C in the germination bed. During the soaking period, the water temperature is strictly controlled, and the water is changed three to four times, each time soaking for 5-8 hours....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com