Extracting method for copper in slag of copper smelting converter

An extraction method and converter slag technology, applied in solid separation, flotation, etc., can solve the problems of wide particle size range, uneven particle size of metal copper embedding, and unsatisfactory copper metal recovery, so as to improve the recovery rate and reduce the dosage of chemicals , cost-saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] The test was carried out on the converter slag of Shandong Hengbang Copper Smelting Co., Ltd., the chemical composition of the raw ore: Cu: 5.90%, T Fe: 45.68% (weight), and a copper ore dressing plant with a daily processing capacity of 800 tons was built.

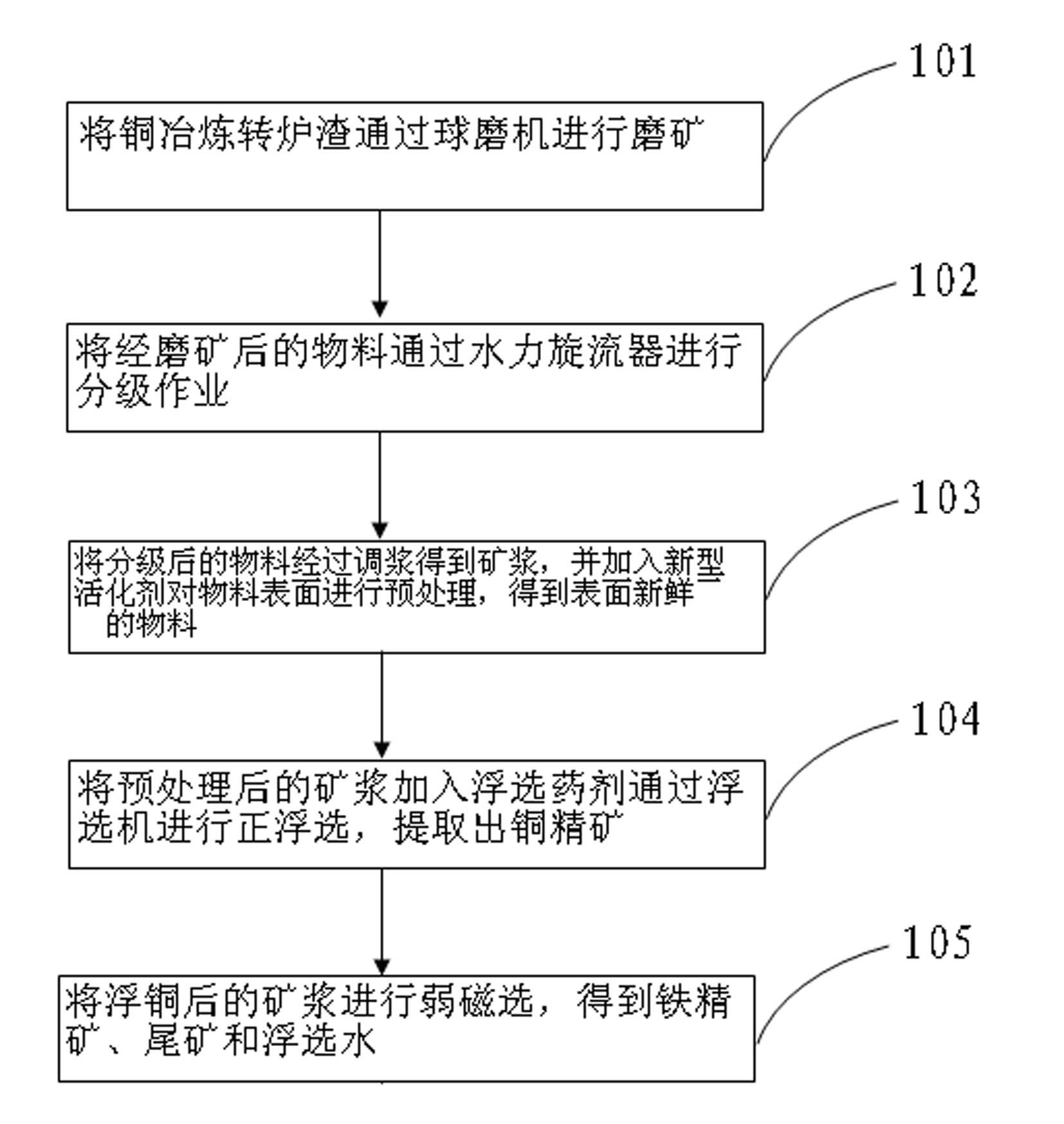

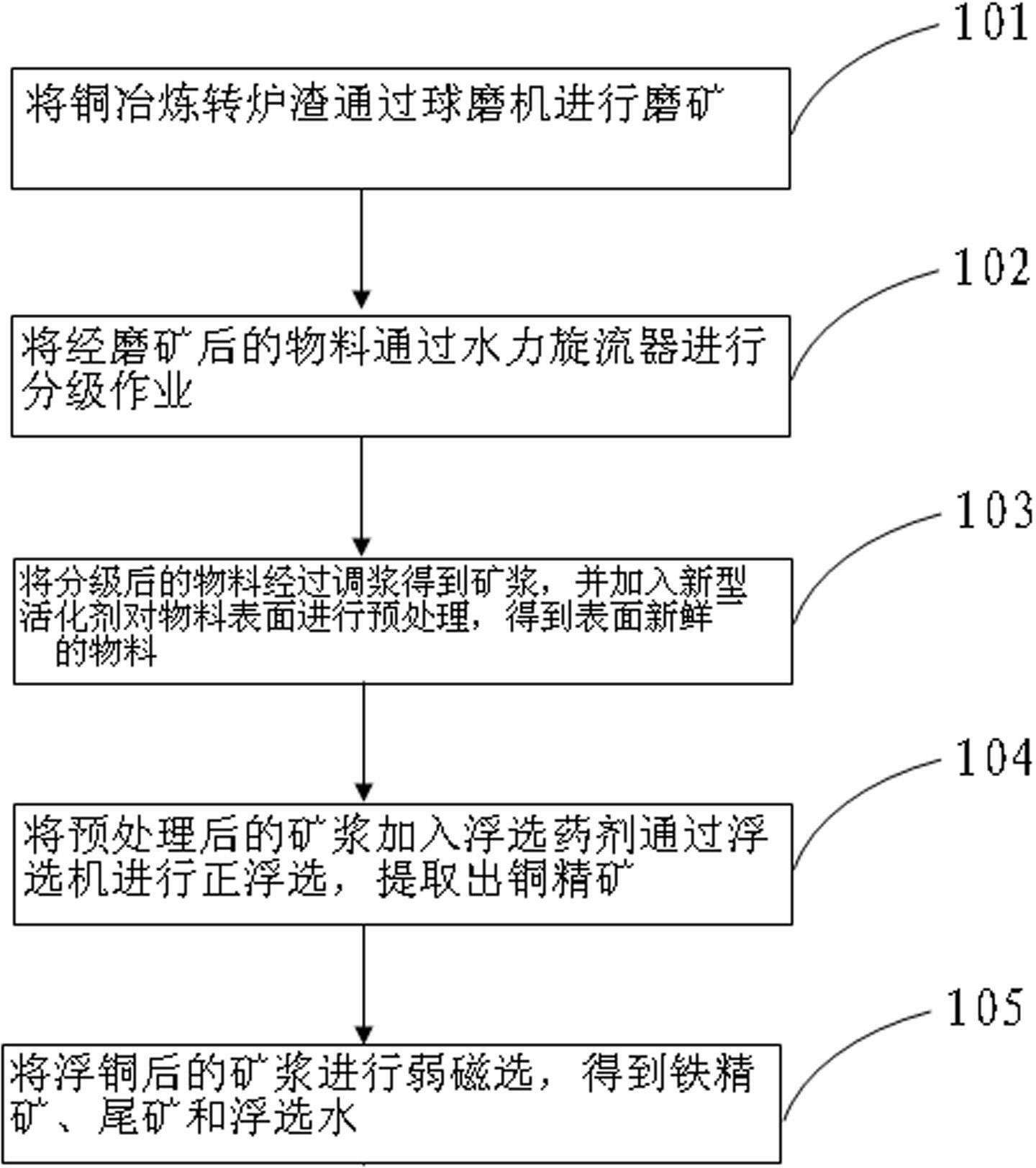

[0033] First, the raw ore is ground by a ball mill; the ground material is classified by a hydrocyclone in two stages to obtain a material ore with a grinding particle size of -200 mesh accounting for 95%; the classified material is pretreated with an activator , the amount of activator: 800g / t; and then use positive flotation to carry out copper flotation respectively. After the flotation agent is added, it will be quickly adsorbed on the surface of the material to make the material float quickly. Dosage: 120g / t; the tailings after floating copper are subjected to weak magnetic separation to obtain iron concentrate, the magnetic field strength: 1200○e; the tailings after weak magnetic separation are dehydrated, and...

Embodiment 5

[0041] Conducted experiments on Penghui copper smelting slag, and built a copper ore dressing plant with a daily processing capacity of 120 tons. The operation effect is very good. The chemical composition of the raw ore: Cu: 3.1-7.3%

[0042] Firstly, the raw ore is ground through a ball mill; the ground material is subjected to two-stage classification by a hydrocyclone to obtain a material with a grinding particle size of -325 mesh accounting for 85%; the classified material is pretreated, and the amount of activator : 500g / t; and then use positive flotation to carry out copper flotation respectively, and obtain copper fine powder through two coarse and two sweeping operations. Iron concentrate, magnetic field strength: 10000e; tailings after weak magnetic separation are dehydrated, and tailings are dry discharged; and the flotation water obtained by positive flotation is recycled and reused.

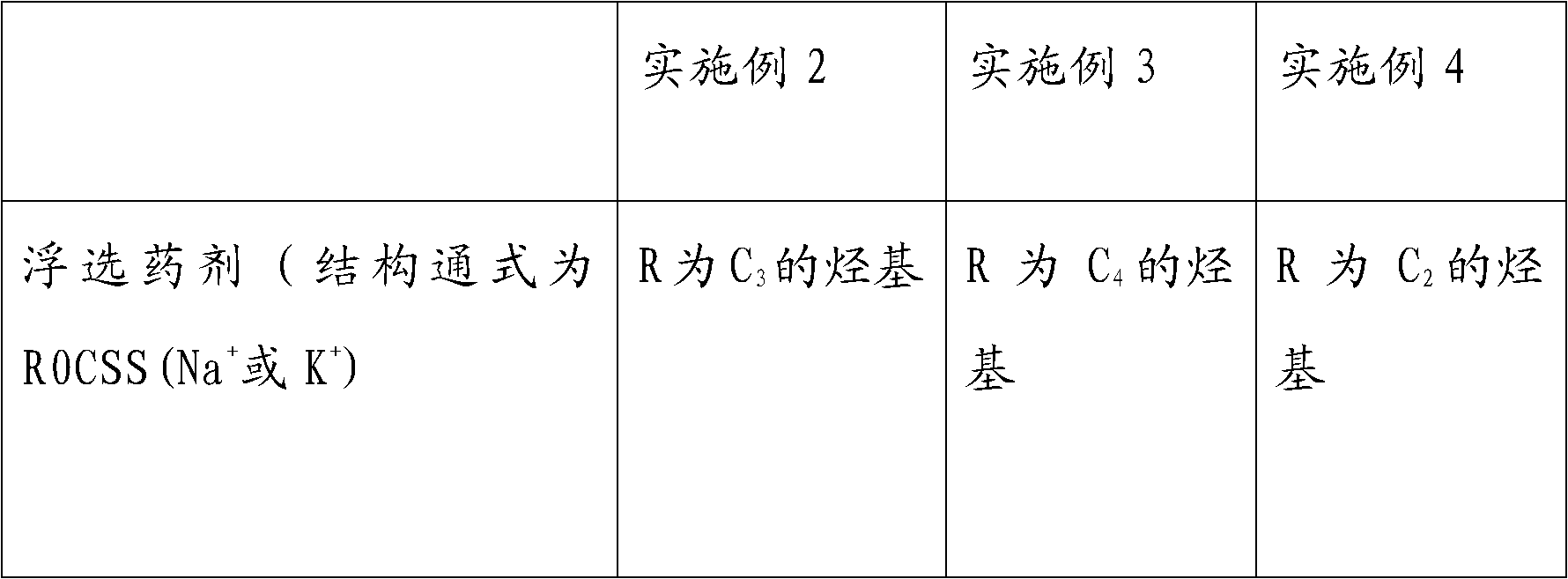

[0043] Wherein, the flotation agent is a sulfide ore collector, and its general ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com