Preparation method of p-Si-based hetero-structure with large magneto-resistance effect

A heterogeneous structure and magnetoresistance technology, applied in the manufacture/processing of electromagnetic devices, ion implantation plating, coating, etc., can solve the problems of low spin injection efficiency and mismatching of magnetic film resistivity, etc., and achieve easy Implementation, good protection, and performance-enhancing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

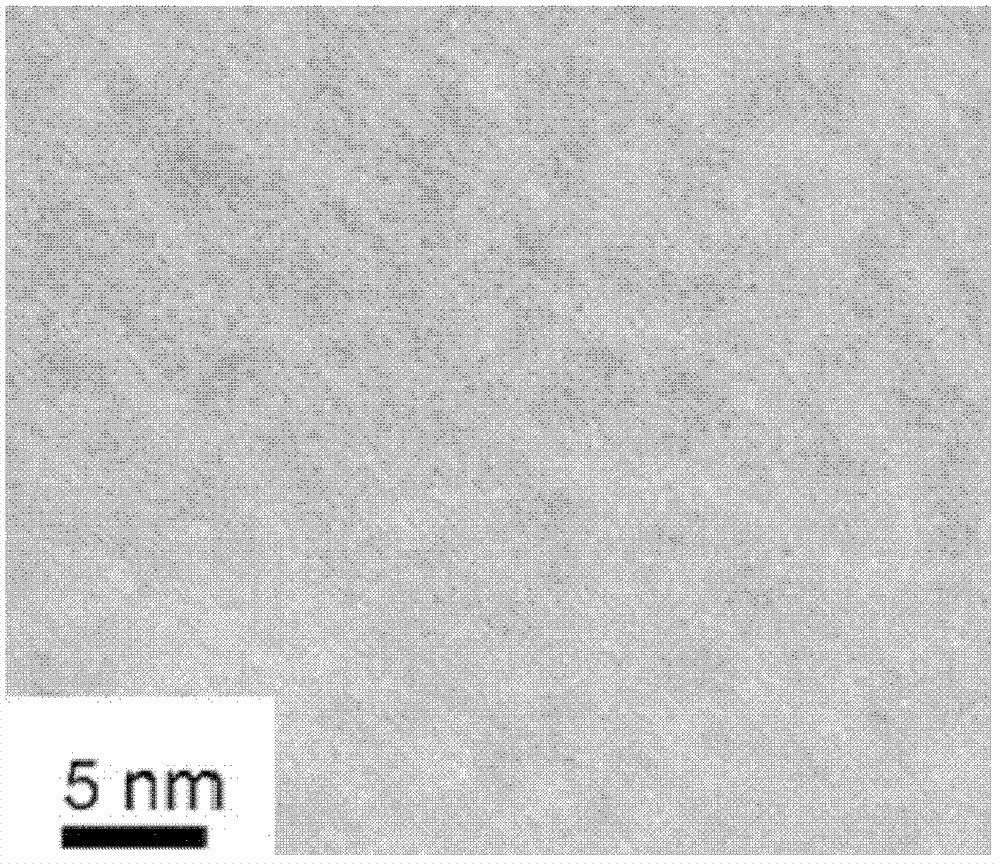

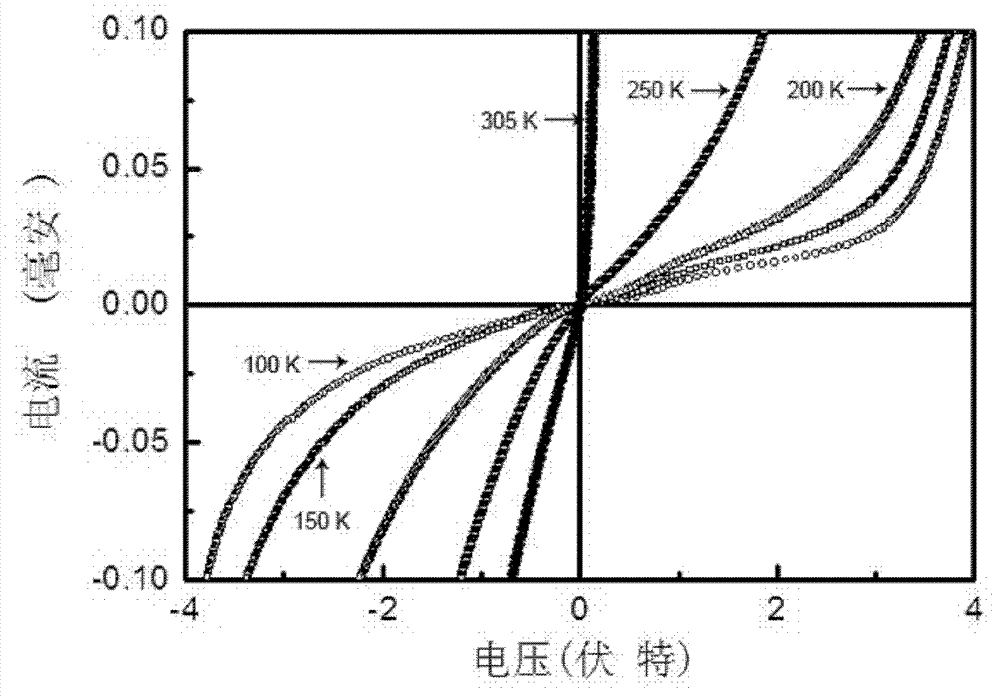

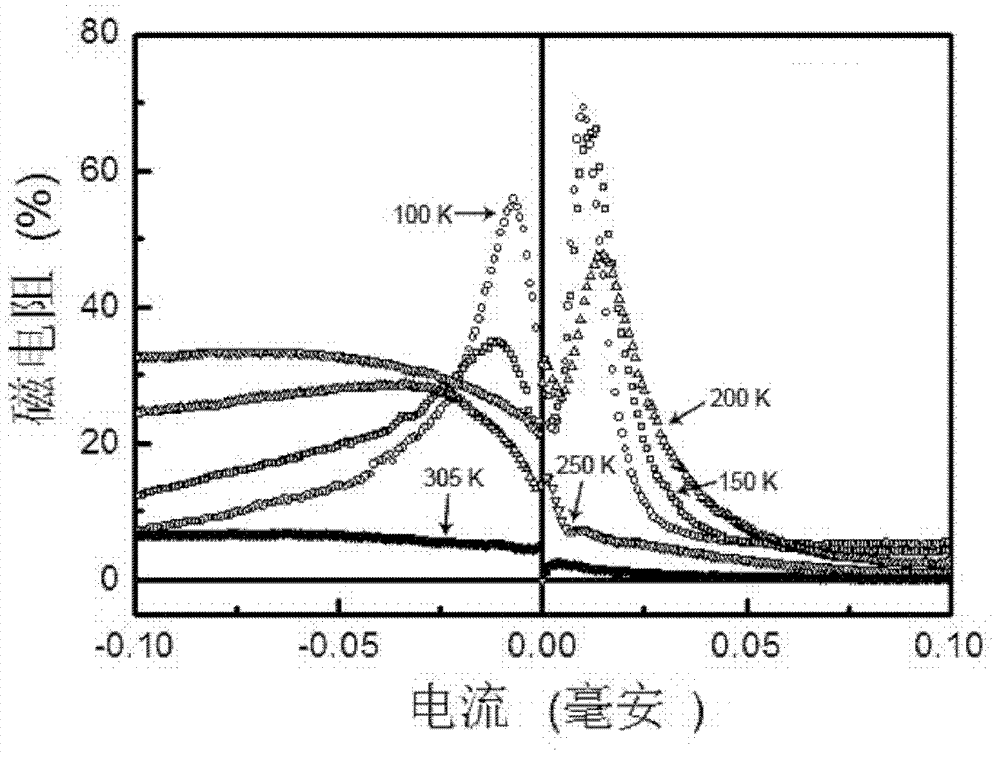

[0022] According to the structure and property analysis of the samples prepared in the present invention, the best implementation mode of preparing Ni-CN / p-Si heterostructure with large magnetoresistance effect will be described in detail below.

[0023] The magnetron sputtering equipment in this embodiment adopts the DPS-II opposite-target magnetron sputtering coating machine produced by the Shenyang Scientific Instrument Development Center of the Chinese Academy of Sciences.

[0024] A method for preparing a p-Si-based heterostructure with a large magnetoresistance effect This patent operates, and the steps are as follows:

[0025] 1) Install a pair of graphite targets with a purity of 99.99% on the target head of the facing target magnetron sputtering coating machine. The thickness of the target is 6 mm and the diameter is 100 mm; uniformly fixed on the graphite target with a purity of 99.99% The Ni sheet, the area of the Ni sheet is 0.5 cm 2 , place 9 slices;

[0026] ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com