Maca composite beverage and preparation method thereof

A compound and beverage technology, which is applied in the field of maca compound beverage and its preparation, can solve the problems of slow absorption and low utilization rate, and achieve the effects of relieving stress, improving efficacy, and enhancing male function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

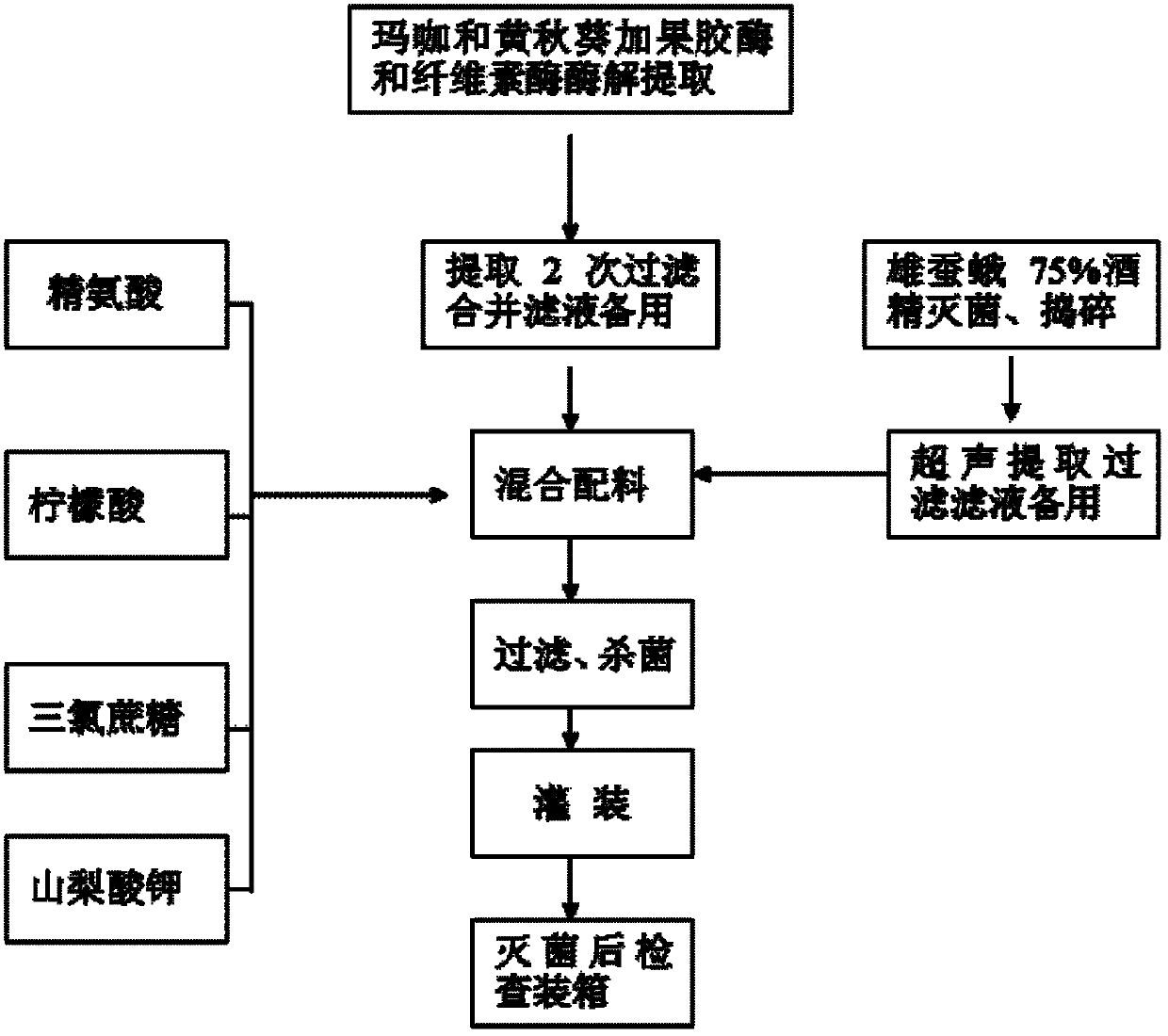

Method used

Image

Examples

Embodiment 1

[0027] Maca compound beverage, calculated on the basis of 1000kg, is made from the following raw materials:

[0028] Maca 15kg, okra 20kg, male silk moth 2.5kg, arginine 0.25kg, potassium sorbate 0.15kg, citric acid 2.5kg, sucralose 0.15kg and purified water.

[0029] (1) Maca and okra are washed with water, drained and pulverized to obtain a mixed powder of Maca and okra; water that is 10 times the weight of the mixed powder of Maca and okra is added to the mixed powder of Maca and okra. 0.25% cellulase by total weight of maca and okra raw materials and 0.25% pectinase by total weight of maca and okra raw materials were slowly stirred at 55° C. for 2 hours to carry out enzymolysis reaction, then heated to a boiling state and maintained for 1 hour, Filtrate to obtain the filtrate, add water to the filter residue that is 5 times the weight of the mixed powder of maca and okra and boil for half an hour, filter, and combine the filtrate twice to obtain the extract of maca and okr...

Embodiment 2

[0036] Maca compound beverage, calculated on the basis of 1200kg, is made from the following raw materials:

[0037] Maca 20kg, okra 30kg, male silk moth 5kg, arginine 0.5kg, potassium sorbate 0.5kg, citric acid 3.5kg, sucralose 0.08kg and purified water.

[0038] (1) Maca and okra are washed with water, drained and pulverized to obtain a mixed powder of Maca and okra; water that is 15 times the weight of the mixed powder of Maca and okra is added to the mixed powder of Maca and okra, and is maca and okra mixed powder. 0.35% cellulase by total weight of maca and okra raw materials and 0.35% pectinase by total weight of maca and okra raw materials were slowly stirred at 45°C for 3 hours to carry out enzymolysis reaction, then heated to a boiling state and maintained for 0.5 hours, Filtrate to obtain the filtrate, add water 10 times the weight of the maca and okra mixed powder to the filter residue and boil for 1 hour, filter, and combine the two filtrates to obtain the maca and o...

Embodiment 3

[0045] Maca compound drink, calculated on the basis of 800kg, is made of the following raw materials:

[0046] Maca 10kg, okra 10kg, male silk moth 1kg, arginine 0.1kg, potassium sorbate 0.1kg, citric acid 1kg, sucralose 0.05kg and purified water.

[0047] (1) Maca and okra are washed with water, drained and pulverized to obtain Maca and okra mixed powder; add water that is 12 times the weight of Maca and okra mixed powder in the Maca and okra mixed powder, which is maca 0.1% cellulase by total weight of maca and okra raw materials and 0.1% pectinase by total weight of maca and okra raw materials were slowly stirred at 60° C. for 5 hours to carry out enzymolysis reaction, then heated to a boiling state and maintained for 45 minutes, Filtrate to obtain the filtrate, then add water 8 times the weight of the maca and okra mixed powder to the filter residue and boil for 45 minutes, filter, and combine the two filtrates to obtain the maca and okra extract;

[0048] (2) Soak the ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com