Antigravity liquid evaporator

A liquid evaporation and anti-gravity technology, which is applied in evaporator accessories, evaporation, spray evaporation, etc., can solve the problems of reduced evaporation performance, increased equipment height, high cost, etc., and achieves reduced processing costs, simplified structure, and reduced energy consumption. consumption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

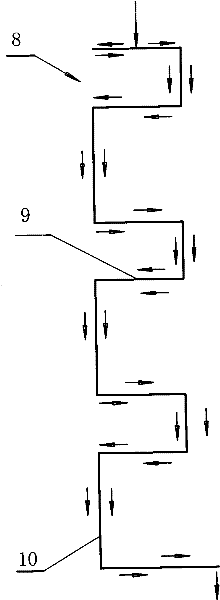

[0028] The general idea of the present invention is to replace the vertical flow with liquid translation, especially to make the liquid overcome the gravity and rely on internal molecular gravity to translate on the lower side of the plane or slope, so as to obtain more uniform dispersion and make the volatile substances more thorough. Evaporate.

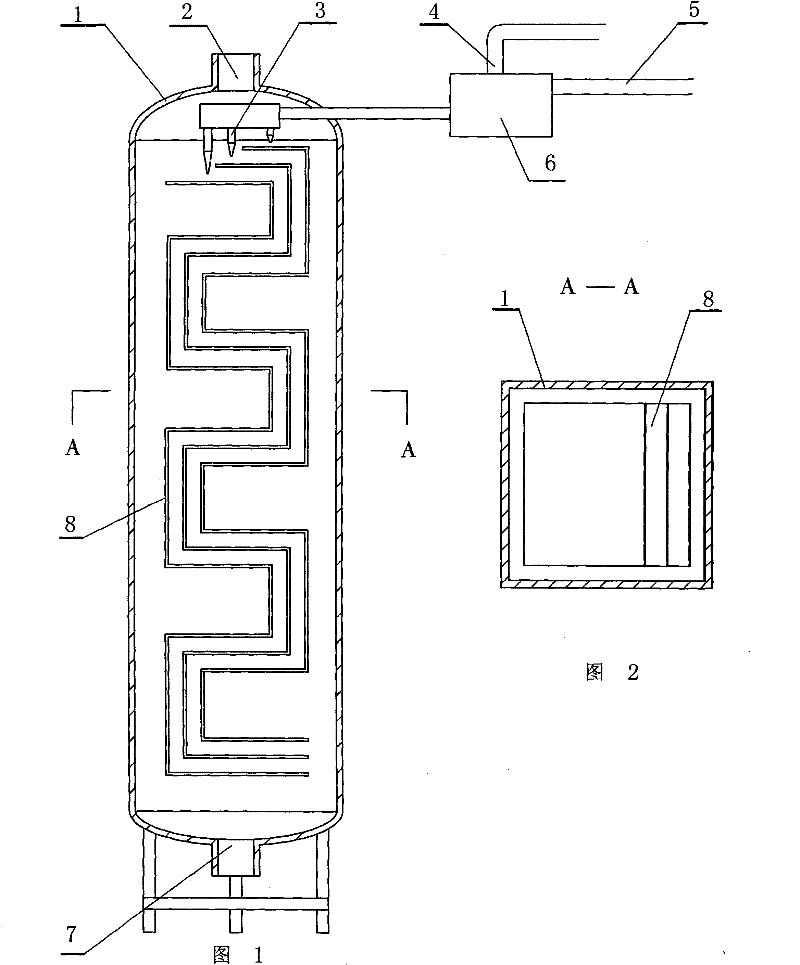

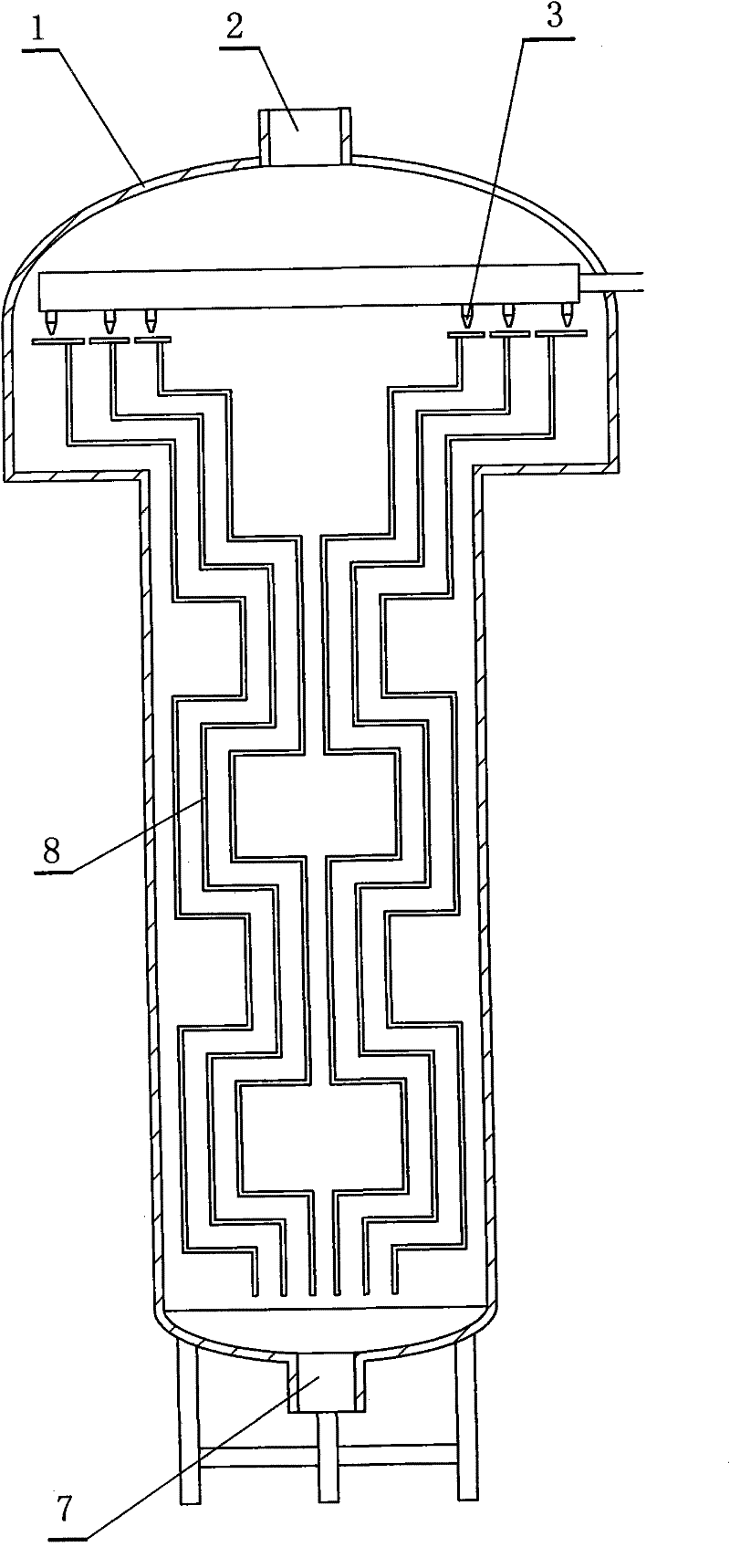

[0029] The first embodiment: as figure 1 , 2 As shown, this evaporator has a thin and tall hollow tank body 1, the cross section of the tank body 1 can be one of shapes such as rectangle, prism, circle or ellipse, and there is an upper opening 2 on the top of the tank body 1, There is a lower port 7 at the lower end, the upper port 2 can be connected to a vacuum device, and the lower port 7 is a discharge port, which is opposite to the steam pipe. On the upper part of the tank body 1, a liquid spray nozzle 3 is provided, and the liquid spray nozzle 3 communicates with the infusion tube 5. The infusion tube 5 is equipped with a g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com