Green lost foam casting technology

A lost foam casting and process technology, applied in the direction of manufacturing tools, casting molding equipment, casting molds, etc., can solve problems such as gaps, and achieve the effect of expanding the scope, avoiding technical obstacles, and reducing carbon content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

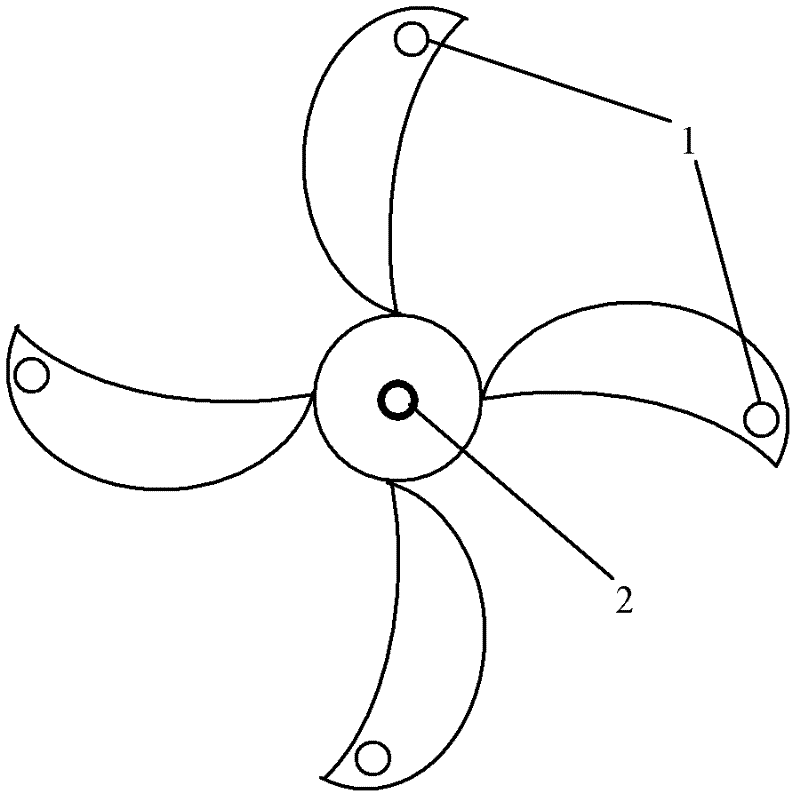

[0022] Now in conjunction with accompanying drawing, the present invention is described in further detail:

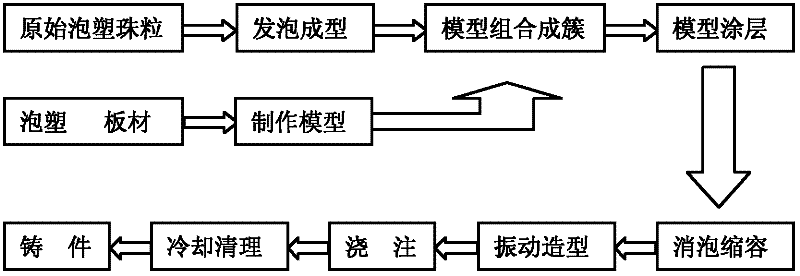

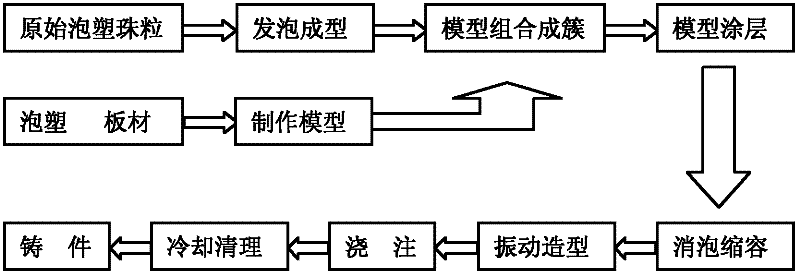

[0023] Such as figure 1 The green lost foam casting process shown includes the following steps:

[0024] (1) Model making:

[0025] Usually there are two situations:

[0026] The first one is made of foam plastic beads, after pre-foaming-curing-foaming-molding-cooling;

[0027] Among them, regarding the selection of foam beads:

[0028] There are three types of foam beads for lost foam casting.

[0029] a. Expandable polystyrene resin beads (referred to as EPS);

[0030] b. Expandable methyl methacrylate and styrene copolymer resin beads (STMMA for short);

[0031] c. Expandable polymethyl methacrylate resin beads (EPMMA for short).

[0032] Expandable polystyrene resin beads (EPS) are commonly used for casting non-ferrous metals, gray iron and general cast steel.

[0033] Bead characteristics: translucent beads, pre-expansion ratio 40-60, particle size 0.18-0.8...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com