Method for processing organic waste water

A technology for organic waste water and waste water, which is applied in chemical instruments and methods, reduced water/sewage treatment, oxidized water/sewage treatment, etc. It can solve problems such as difficult to adapt to complex components, easy deactivation of catalysts, harsh environmental conditions, etc., to achieve Avoid rapid corrosion or deactivation, environmental friendliness, and protect human health

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

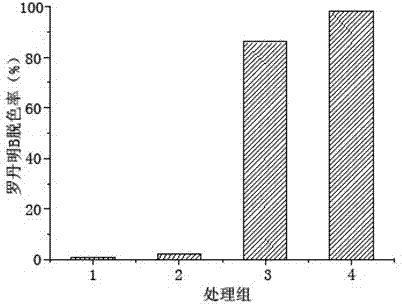

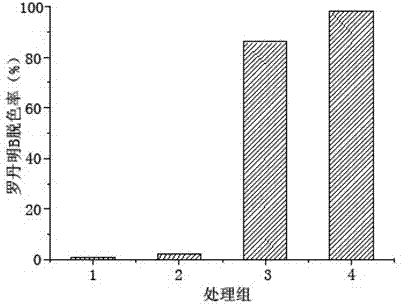

Image

Examples

Embodiment 1

[0020] Polyethylene-coated waste iron wire with a diameter of 5mm and a length of 20cm exposes the circumference every two centimeters. As the stirring blade of the mixer, it can efficiently reduce the azo dyes in the range of pH3 to pH7, and can dissolve 200mL of the solution in half an hour 100mg / L methyl orange, reactive brilliant red and other dyes are completely decolorized, significantly improving their biodegradability (the lower the pH, the shorter the treatment time, for example, when the pH is 3, the reaction time is less than 10 minutes, and 100mg / L formazan in 200mL solution can be decolorized. base orange, reactive brilliant red and other dyes are completely decolorized). The cost of the material is low, the production process is simple, and the efficiency drops by less than 5% after repeated 30 times. At the same time, it is easy to operate and can be used with different devices to efficiently treat dye wastewater.

Embodiment 2

[0022] Polypropylene-coated iron wire with a diameter of 5mm and a length of 20cm exposes the circumference every two centimeters. As the stirring blade of the mixer, it can efficiently reduce and treat chlorophenol organic pollutants in the range of pH3 to pH7 (the lower the pH, the shorter the treatment time ), the dechlorination rate of 10mg / L pentachlorophenol, o-chlorophenol and other chlorophenol organic pollutants in 200mL solution can be as high as 75% within one hour, which significantly improves its biodegradability. The cost of the material is low, the production process is simple, and the efficiency drops by less than 10% after repeated ten times. At the same time, it is easy to operate and can be used with different devices to efficiently treat chlorophenol organic wastewater.

Embodiment 3

[0024] The exposed side of the polyethylene-coated iron plate (2m × 2m × 0.5cm) is used as the stirring blade of the mixer, which can efficiently oxidize and degrade chlorophenol organic pollutants in the range of pH3 to pH7 (the lower the pH, the shorter the treatment time). Chlorophenol organic pollutants such as 50mg / L pentachlorophenol and o-chlorophenol in a 200mL solution can be completely degraded within hours. The cost of the material is low, the production process is simple, and the efficiency drops by less than 10% after repeated 30 times. At the same time, it is easy to operate and can be used with different devices to efficiently oxidize and degrade chlorophenol organic wastewater.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com