Hydantoin epoxy resin composite for encapsulating semiconductor devices

A technology of hydantoin epoxy resin and epoxy resin, which is applied in the direction of semiconductor devices, semiconductor/solid-state device parts, electric solid-state devices, etc., can solve problems that have not been seen, and achieve good manufacturability and excellent dielectric strength Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

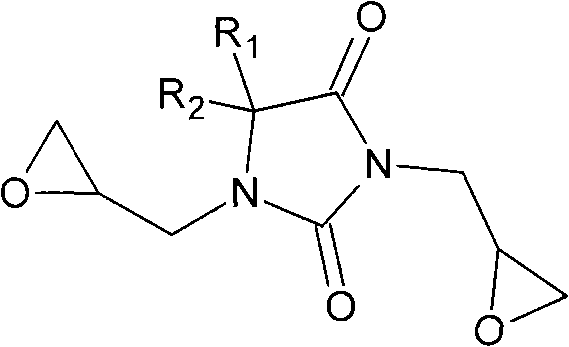

Method used

Image

Examples

preparation example Construction

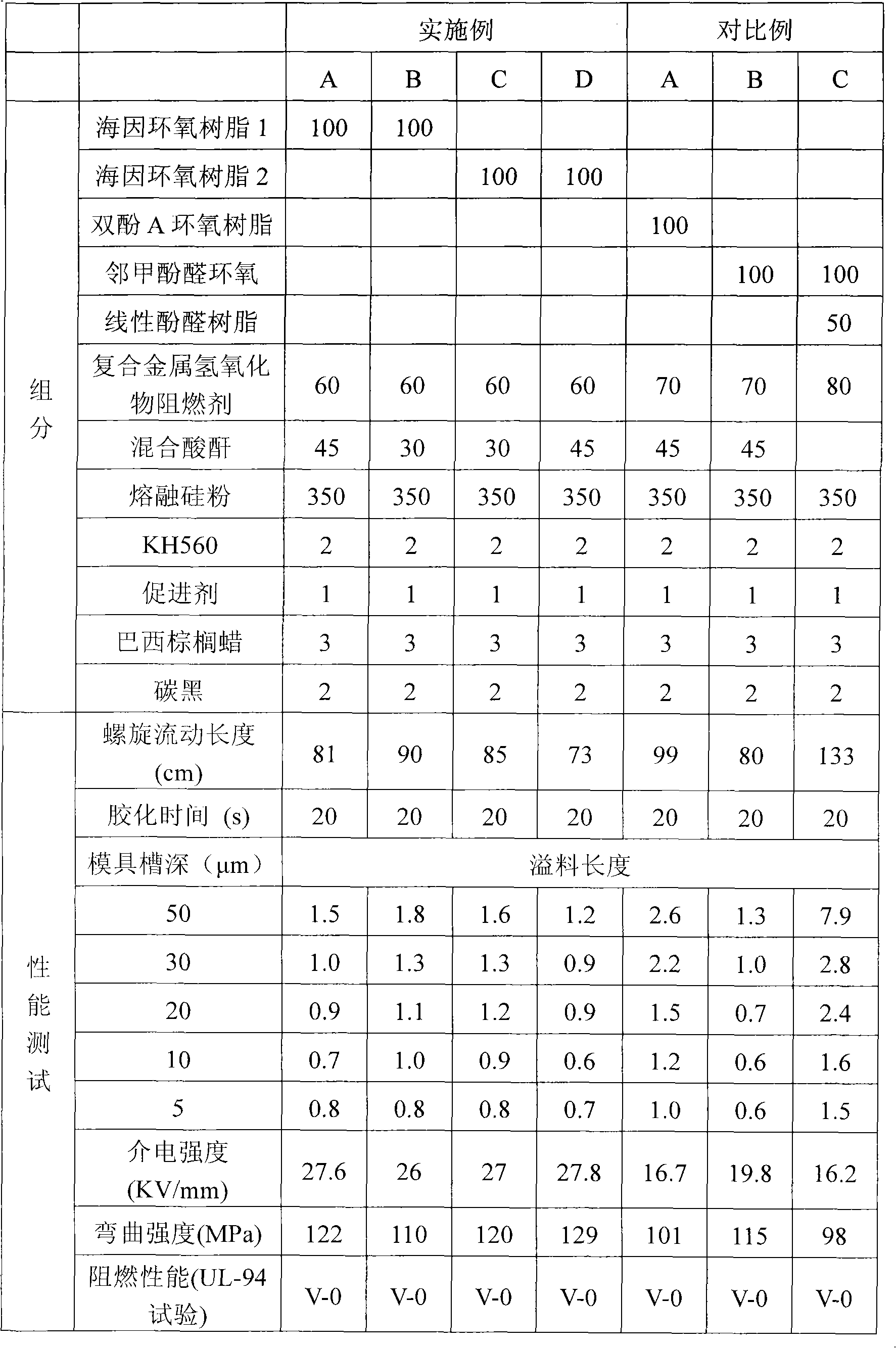

[0040] The preparation method of the present invention is to mix heterocyclic hydantoin epoxy resin, mixed acid anhydride, molten silicon powder, composite metal hydroxide flame retardant, accelerator TPP, carnauba wax, carbon black, The joint agent is put into a double-roller plastic mill, mixed at 80-100°C, cooled and pulverized.

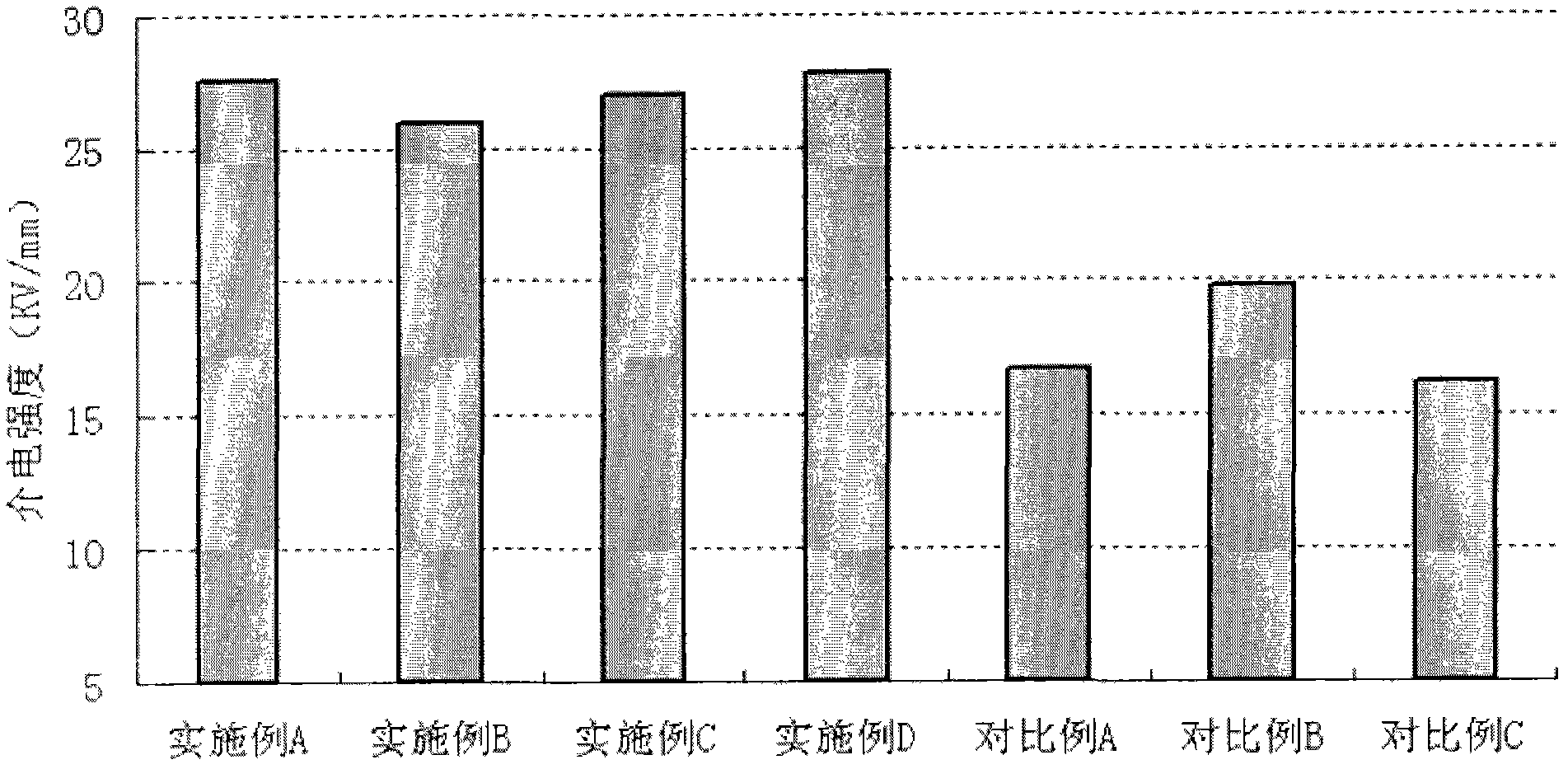

[0041] The epoxy resin composition of the invention can be used as packaging material for high-voltage components and integrated circuits, and has excellent dielectric strength and high-temperature resistance. The dielectric strength is about 30-60% higher than that of bisphenol A epoxy and o-cresol novolac epoxy resin composition, and has good manufacturability at the same time, and is suitable for the packaging of high-voltage resistant components.

Embodiment A

[0044] The heterocyclic hydantoin epoxy resin was mixed with MHR-018 and MHR-154 purchased from Wuxi Meihua Chemical Co. Oxygen value 0.52-0.55, softening point 15°C) 100 parts, mixed anhydride (trimellitic anhydride and methylnadic anhydride mixed by weight 7:3) 45 parts, accelerator TPP 1 part, molten silicon powder 350 parts, silane coupling agent (KH560) 2 parts, carnauba wax 3 parts, carbon black 2 parts, the above raw materials were mixed evenly in a double-roller rubber mixer, the mixing temperature was 80-100 ° C, after mixing, cooled and pulverized to make a sample powder.

Embodiment B

[0046] The selected components except mixed acid anhydride (trimellitic anhydride and tetrahydrophthalic anhydride mixed by weight 8:2) are 30 parts, 1 part of accelerator 2-phenyl-4-methylimidazole, and other components are the same as those in Example A Identical, its preparation method is also identical with embodiment A.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Softening point | aaaaa | aaaaa |

| Softening point | aaaaa | aaaaa |

| Softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com