Bell-shaped ZnO nanometer device material and preparation method thereof

A technology of nano-devices and nano-materials, applied in the direction of nano-structure manufacturing, nano-technology, nano-technology, etc., can solve the problems of bell-shaped zinc oxide nano-structures that have not yet been seen, and achieve superior performance, simple operation steps, and short production cycle Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

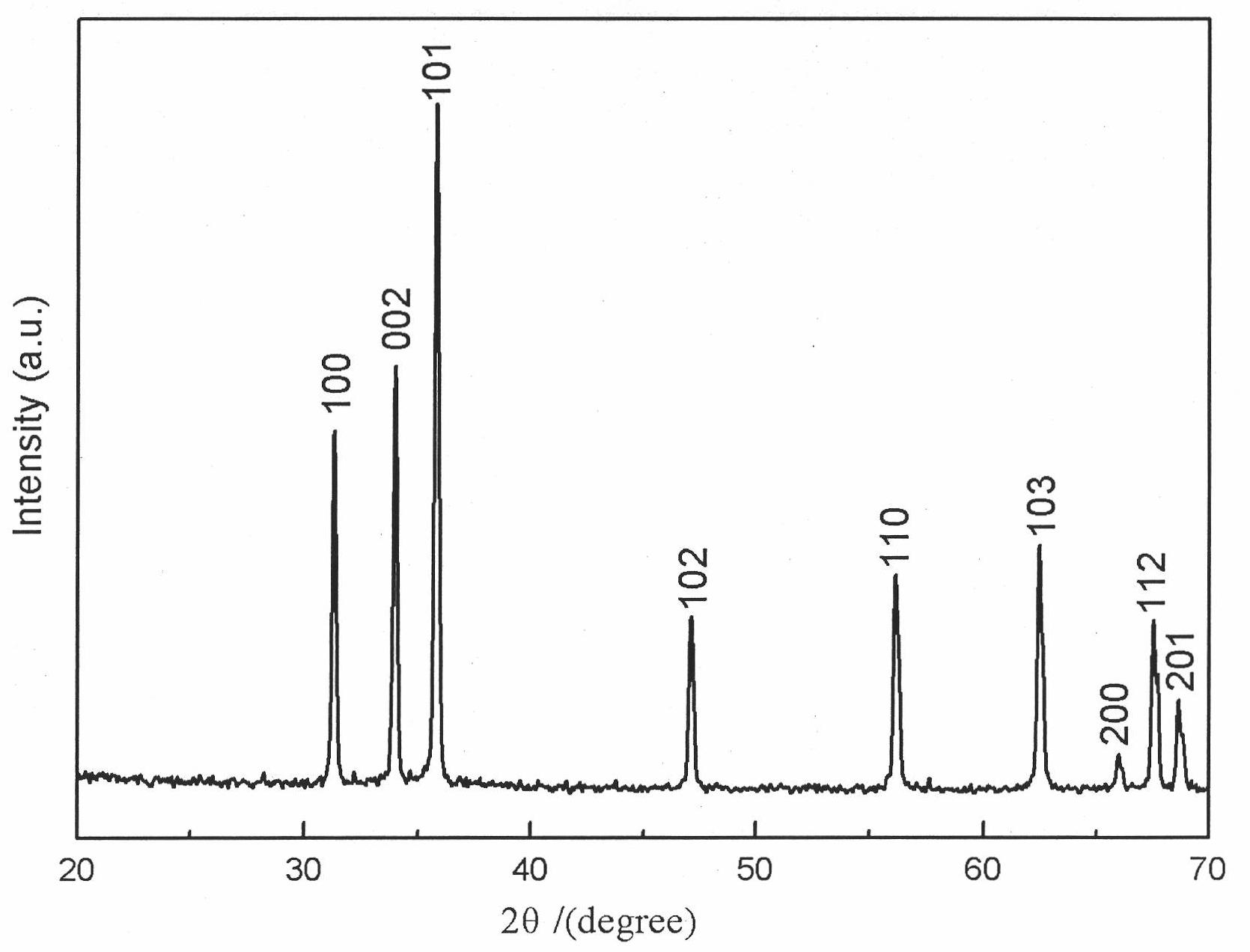

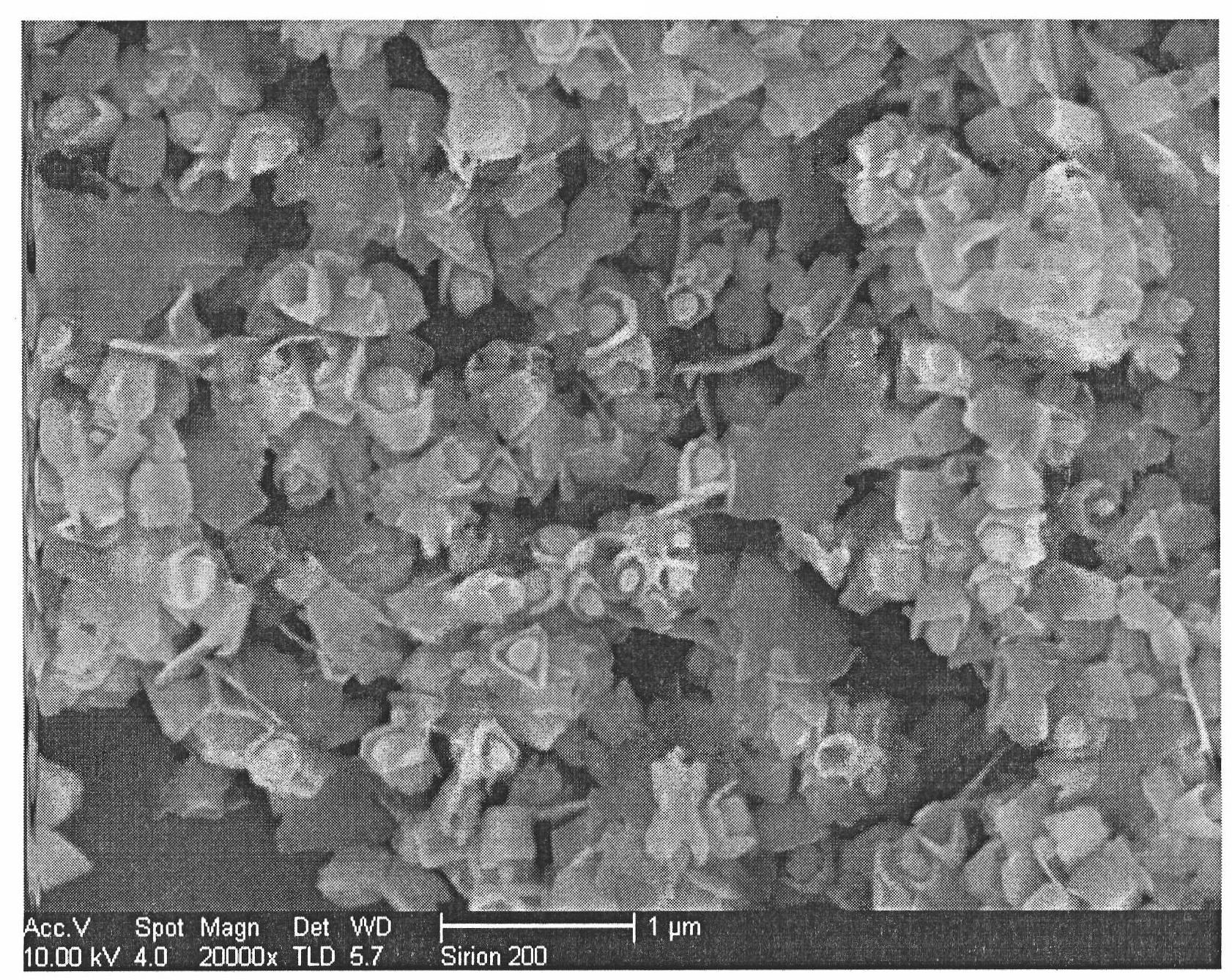

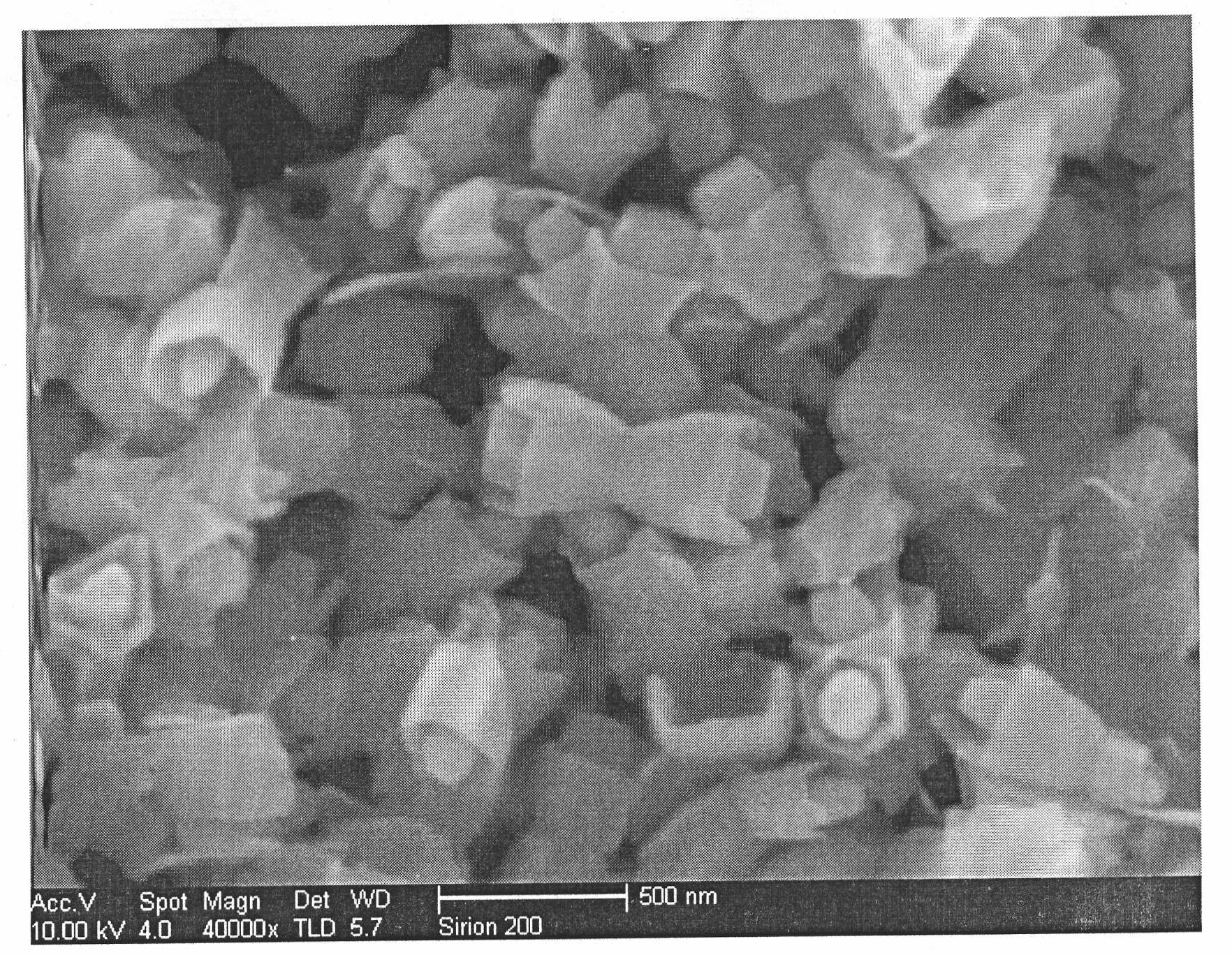

[0024] The present invention adopts a one-step ultrasonic irradiation method to prepare bell-shaped ZnO nano-device materials, that is, soluble zinc salt, deionized water and hexamethylenetetramine are used as raw materials, and a precursor solution is obtained after stirring and dissolving. The solution was generated after ultrasonic irradiation. Its specific process steps are as follows:

[0025] (1) Take 0.2193g zinc acetate and be mixed with 10mL deionized water to make solution A;

[0026] (2) Weigh 0.6999g hexamethylenetetramine and prepare solution B with 50mL deionized water, the molar ratio of zinc salt and hexamethylenetetramine is 1:5;

[0027] (3) While stirring, add solution A to solution B to form precursor solution C, the total volume of the solution is 60mL, and continue to stir for 10 minutes;

[0028] (4) Transfer the precursor solution C to a 100mL sealed threaded bottle, place it in an ultrasonic cleaner filled with tap water at 80°C, and irradiate it wit...

Embodiment 2

[0034] The present invention adopts a one-step ultrasonic irradiation method to prepare bell-shaped ZnO nano-device materials, that is, soluble zinc salt, deionized water and hexamethylenetetramine are used as raw materials, and a precursor solution is obtained after stirring and dissolving. The solution was generated after ultrasonic irradiation. Its specific process steps are as follows:

[0035] (1) Take by weighing 0.2195g zinc acetate and be mixed with solution A with 10mL deionized water;

[0036] (2) Weigh 0.700 2g hexamethylenetetramine and prepare solution B with 50mL deionized water, the molar ratio of zinc salt and hexamethylenetetramine is 1:5;

[0037] (3) While stirring, add solution A to solution B to form precursor solution C, the total volume of the solution is 60mL, and continue to stir for 10 minutes;

[0038] (4) Transfer the precursor solution C to a 100mL sealed threaded bottle, place it in an ultrasonic cleaner filled with tap water at 90°C, and irradi...

Embodiment 3

[0043] The present invention adopts a one-step ultrasonic irradiation method to prepare bell-shaped ZnO nano-device materials, that is, soluble zinc salt, deionized water and hexamethylenetetramine are used as raw materials, and a precursor solution is obtained after stirring and dissolving. The solution was generated after ultrasonic irradiation. Its specific process steps are as follows:

[0044] (1) Take 0.2192g zinc acetate and be mixed with 10mL deionized water to make solution A;

[0045] (2) Weigh 0.7001g hexamethylenetetramine and prepare solution B with 50mL deionized water, the molar ratio of zinc salt and hexamethylenetetramine is 1:5;

[0046] (3) While stirring, add solution A to solution B to form precursor solution C, the total volume of the solution is 60mL, and continue to stir for 10 minutes;

[0047] (4) Transfer the precursor solution C to a 100mL sealed threaded bottle, place it in an ultrasonic cleaner filled with tap water at 70°C, and irradiate it wit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com