Acrylic resin-epoxy resin heat preservation coating

A technology of acrylic resin and epoxy resin, applied in the direction of epoxy resin paint, coating, etc., can solve the problems of poor adhesion, failure to achieve the double-layer effect of heat preservation and decoration, peeling and cracking, etc., and achieve strong adhesion and good Heat insulation effect, good alkali resistance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

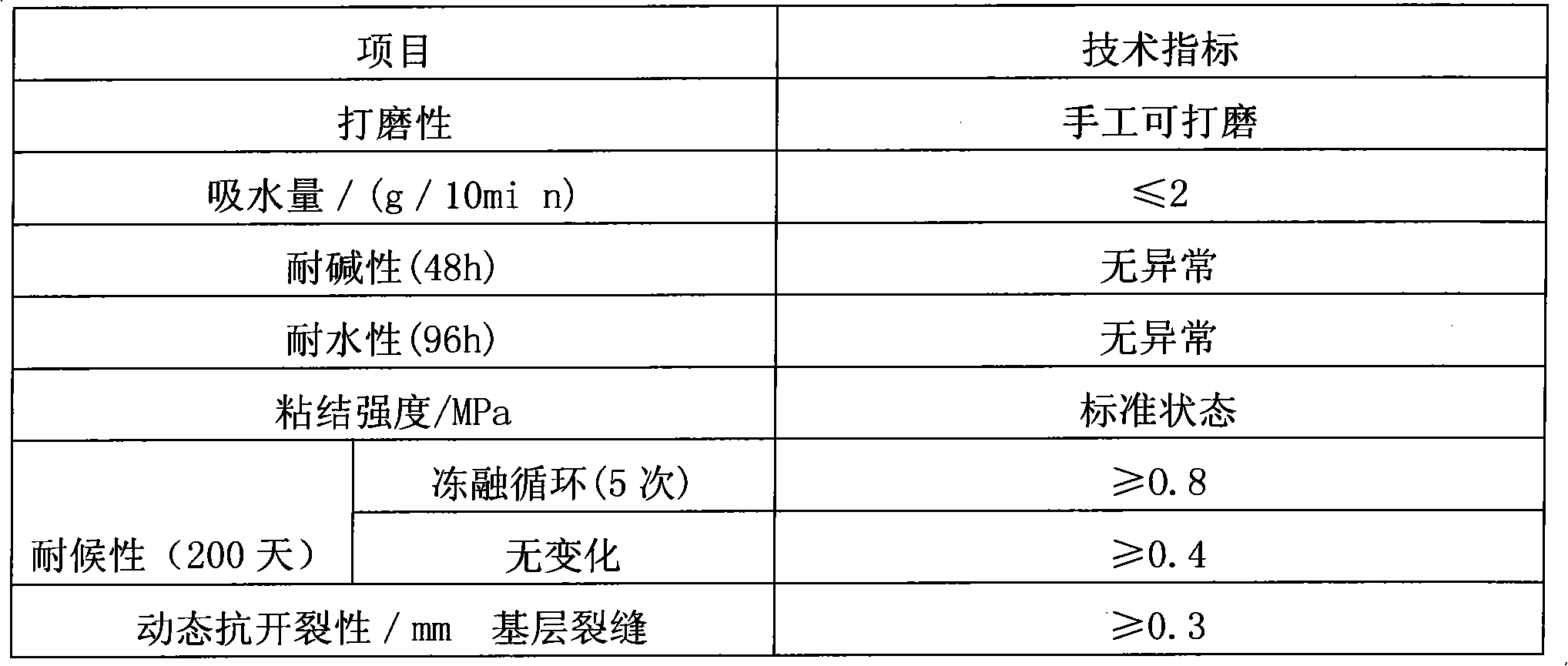

[0011] An acrylic resin-epoxy resin thermal insulation coating is uniformly prepared by high-speed dispersion and stirring with a mixer according to the following raw materials: 50 parts of acrylic resin, 30 parts of closed-cell perlite, 25 parts of cyclohexanone peroxide, 10 parts of methyl Cellulose, 75 parts of epoxy resin, 12 parts of heavy calcium carbonate, 10 parts of sodium citrate, 6 parts of mortar king, 10 parts of petroleum ether, 65 parts of water, 2 parts of defoamer, 8 parts of thickener, 6 parts Film-forming aids. The main technical performance of the product prepared by the present invention is as follows table 1

[0012] Table 1, main technical performance of the present invention

[0013]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com