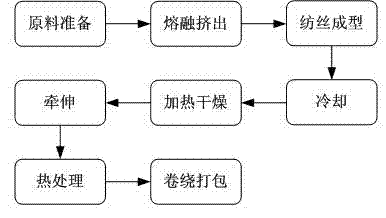

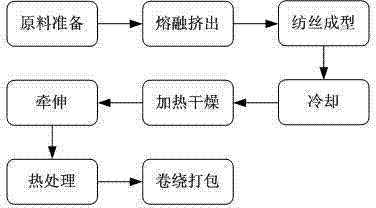

Preparation method of poly(perfluoroethylene-propylene) fiber

A polyperfluoroethylene propylene and fiber technology, which is applied in the field of fluoroplastics processing, can solve the problems of high resin melt viscosity, wire breakage, low modulus processing obstacles, etc., and achieves low cost, improved mechanical strength, and process equipment. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

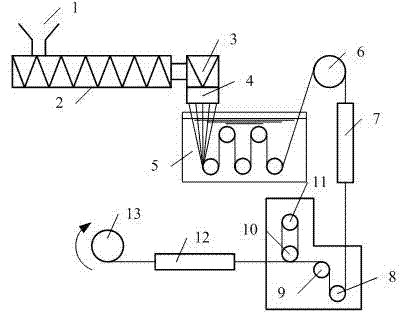

Method used

Image

Examples

Embodiment 1

[0031] (1) The raw material is polyperfluoroethylene propylene resin chips produced by Daikin Company, the brand is NP-20, and the melt index is 4.3-8.7g / 10min;

[0032] (2) Put FEP resin slices into a single-screw extruder with a screw diameter of Φ50mm, and set the temperature of the C1 zone to 260°C, the temperature of the C2 zone to 300°C, and the temperature of the C3 zone to 330°C. The temperature in zone H is 360°C, and the temperature in zone D is 350°C.

[0033] (3) The number of spinneret holes is 3000, the capillary hole diameter is 0.5mm, and the capillary aspect ratio is 2:1. The spinneret was heated to a temperature of 350°C.

[0034] (4) After the resin is formed into fibers, it enters the cooling water tank with rollers. The water temperature of the cooling water tank with rollers is controlled at 70°C, and the length of the fibers passing through the cooling water tank with rollers is 1.5m.

[0035] (5) After cooling, the tow is drawn through the first dryin...

Embodiment 2

[0040] Repeat Example 1, but in step (6), the line speed of the first drafting roll is constant, and the line speed of the second drafting roll is changed to 36m / min, and then the second drawing is carried out through the third drafting roll. The linear velocity of the three drafting rollers was 86.4 mm, and then stretched three times by the fourth drafting roller, and the linear velocity of the fourth drafting roller was 147 m / min. The total draw ratio is 1:12.2, and the heating temperature of the draw rollers is 200°C. The resulting fiber has a wire diameter of 0.02 mm.

[0041] In the present invention, the preparation of polyperfluoroethylene propylene can produce fibers with various wire diameter specifications through adjustable spinning and drawing processes, and the prepared polyfluoroethylene propylene fibers have excellent mechanical strength, durability Thermal properties, chemical resistance, non-adhesiveness, hydrophobicity, low wear and electrical insulation, ca...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com