Method for producing natural gas in organism coal bed

A natural gas and coal seam technology, applied in the combination of clean energy and biotechnology, can solve the problems of affecting gas production efficiency, increasing gas production cost, and blocking coal seam gaps, so as to increase the total gas production, achieve effective absorption, and reduce filling volume effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

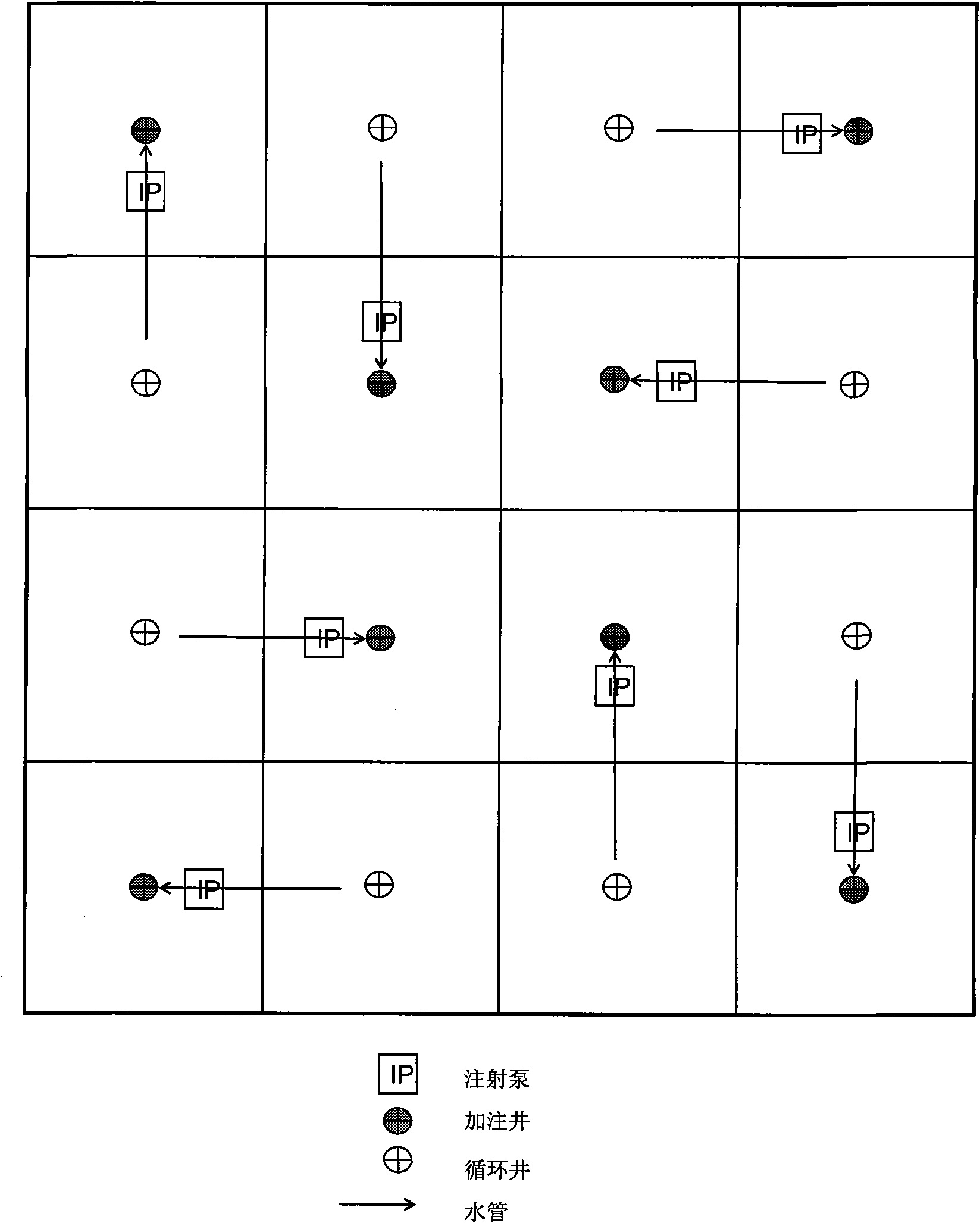

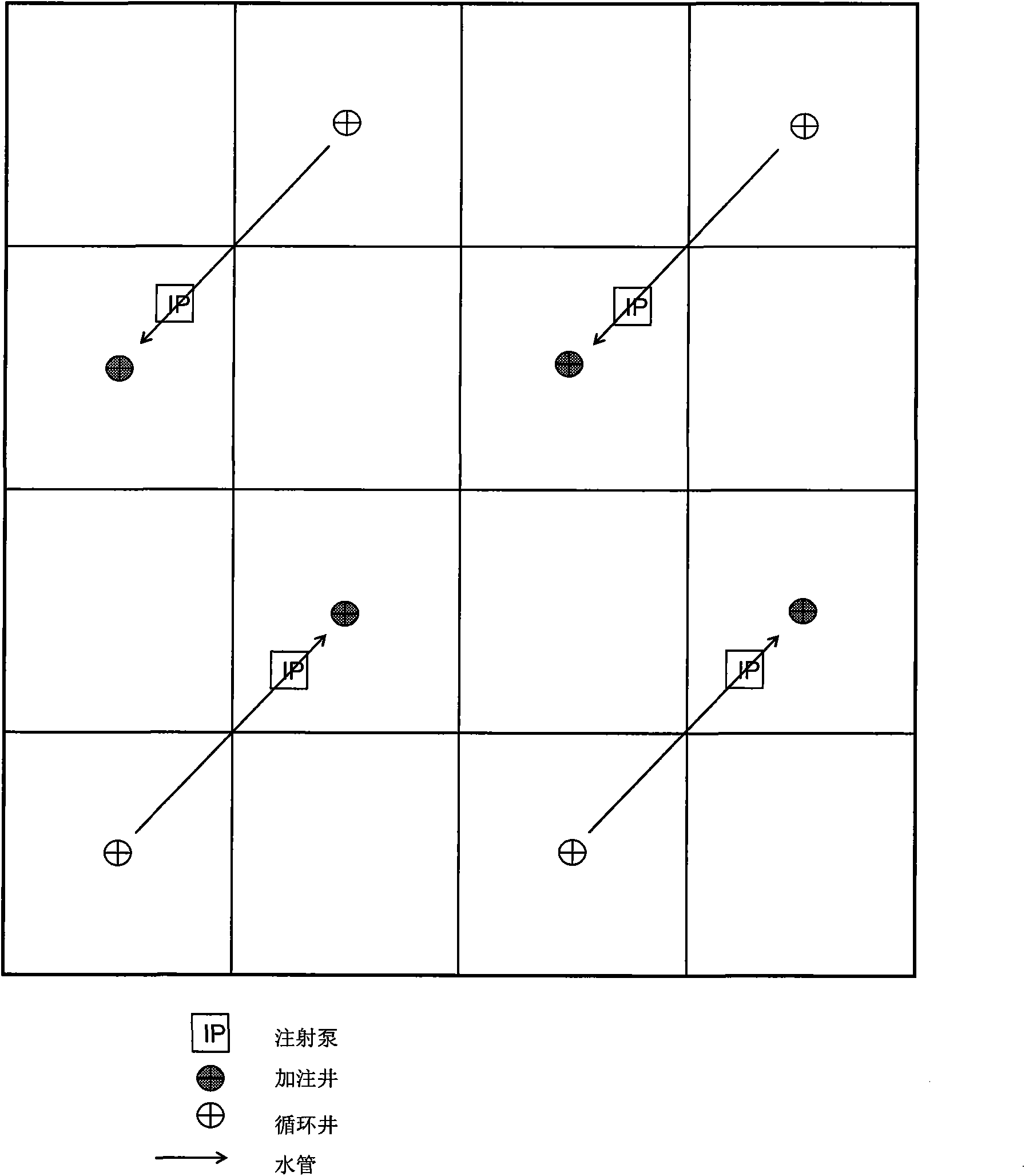

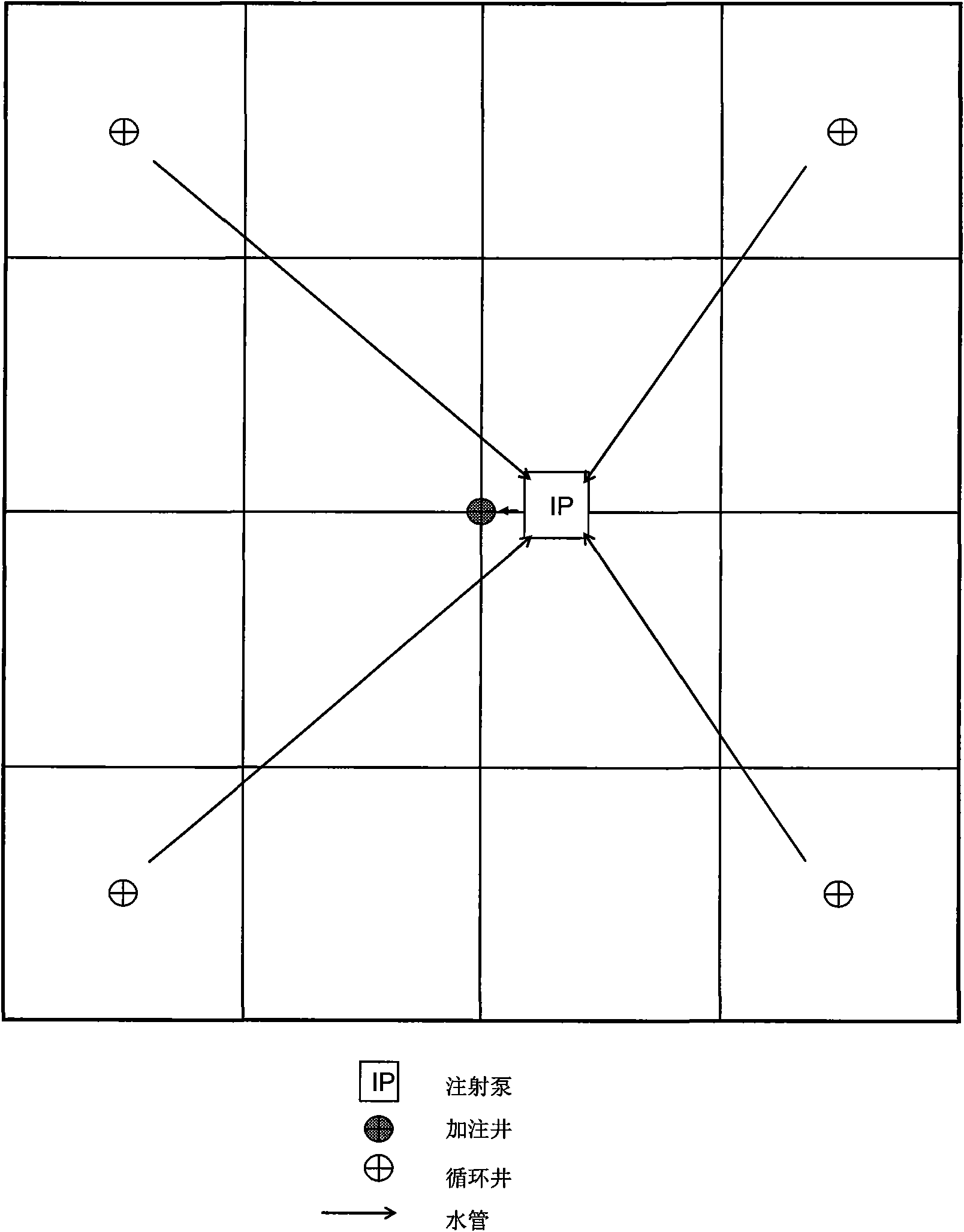

Image

Examples

example

[0047] The following example is the application of the method of the present invention in a semi-bituminous coal seam with a thickness of 20 meters. The specific implementation steps are as follows:

[0048] 1) Confirm whether the target coal seam is suitable for the production of biological coalbed methane by the method of the present invention. Consult local geological data, collect coal core samples and coal seam water for feasibility testing and coal water quality testing. The coal seam is 300 meters above the surface, with a thickness of not less than 20 meters and a total area of 400 square kilometers. The coal seam permeability is not less than 0.5-1.0Darcy. The coal seam is saturated with water, and the water level is 3 meters from the top of the coal seam. The water quality of the coal seam is close to the drinking standard of fresh water. Total Dissolved Solids (TDS) is less than 200 mg / L. The dry state carbon content of this coal seam coal is 70%. The gas pr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Depth | aaaaa | aaaaa |

| Permeability | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com