Preparation method for porous titanium dioxide-carbon combined nano hollow microsphere

A technology of porous titanium dioxide and hollow microspheres, applied in chemical instruments and methods, nanotechnology, nanotechnology, etc., can solve the problems of uneven particle size distribution, low catalyst specific surface area, low photocatalytic activity, etc., and achieve simple process, Efficient adsorption and visible light catalytic degradation, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] a) Weigh 1g of tetraisopropyl titanate (TIOP), add it into a beaker containing 50mL of absolute ethanol, stir to dissolve and disperse evenly, and prepare solution A;

[0033] b) Weigh 1g of furfural and 0.25g of dodecylamine, add 25mL of absolute ethanol, stir to dissolve and disperse evenly, and prepare solution B;

[0034] c) Slowly add solution B dropwise to solution A under vigorous stirring, and continue stirring for 1 hour after dropping;

[0035] d) Add the mixed solution obtained in step c) into a 100mL polytetrafluoroethylene solvothermal reaction kettle, seal the reaction kettle with a steel sleeve, and perform solvothermal reaction: react at 180°C for 12 hours;

[0036] e) After the reaction is completed, cool naturally, and centrifuge. The obtained product is washed with absolute ethanol for 5 times, and then vacuum-dried at 60°C for 4 hours to obtain a brown-yellow powder, which is porous TiO 2 -C (TIOP) composite nano hollow microspheres.

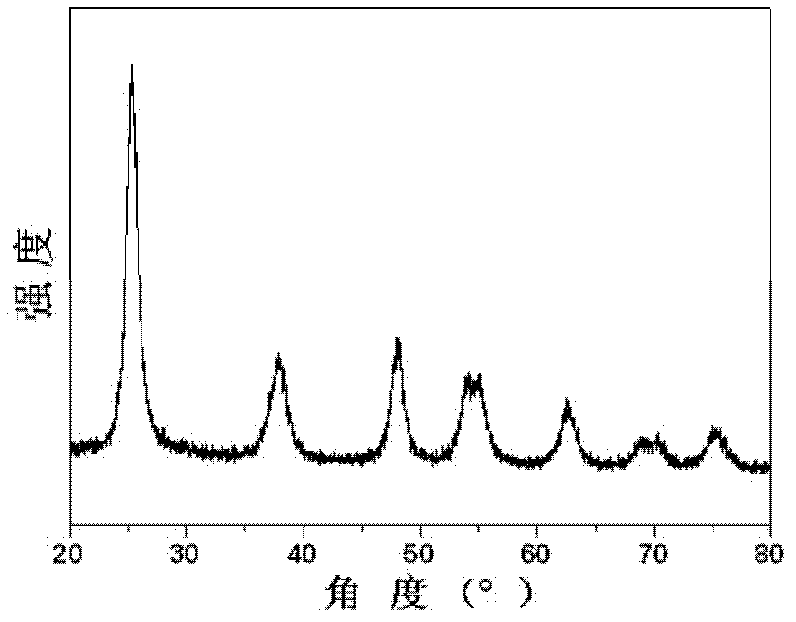

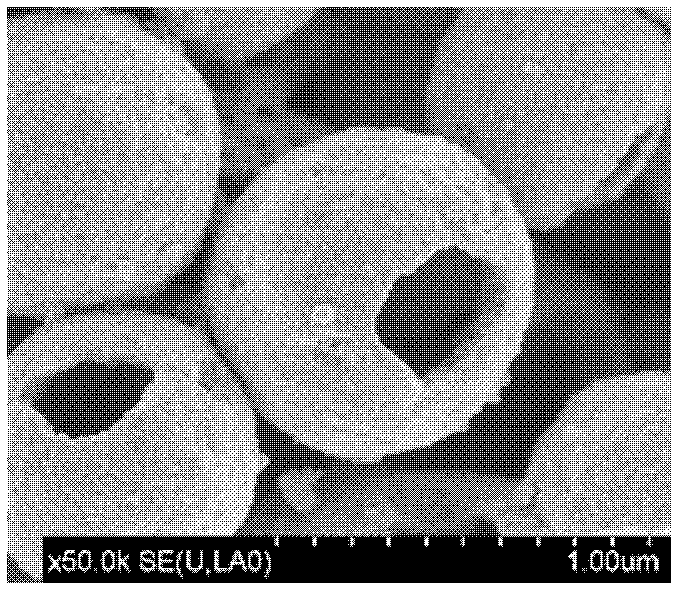

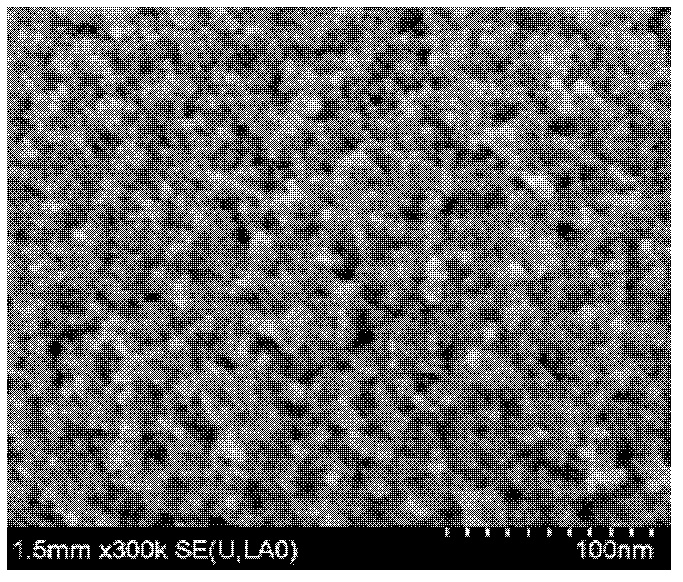

[0037] figu...

Embodiment 2

[0044] a) Weigh 1g of tetra-n-butyl titanate (TBOT), add it into a beaker containing 50mL of absolute ethanol, stir to dissolve and disperse evenly, and prepare solution A;

[0045] b) Weigh 1.5g furfural and 0.4g dodecylamine, add 25mL absolute ethanol, stir to dissolve and disperse evenly, and prepare solution B;

[0046] c) Slowly add solution B dropwise to solution A under vigorous stirring, and continue stirring for 1 hour after dropping;

[0047] d) Add the mixed solution obtained in step c) into a 100mL polytetrafluoroethylene solvothermal reaction kettle, seal the reaction kettle with a steel sleeve, and perform solvothermal reaction: react at 180°C for 12 hours;

[0048] e) After the reaction is completed, cool naturally, and centrifuge to separate the product. The obtained product is washed with absolute ethanol for 5 times, and then vacuum-dried at 80°C for 4 hours to obtain a brown-yellow powder, which is porous TiO 2 -C (TBOT) composite nano hollow microspheres. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com