Calcium plastic starch resin sheets

A technology of starch resin and plasticized starch, which is applied in the field of new calcium-plastic starch sheet, can solve problems such as difficult degradation, and achieve the effects of environmental protection, good natural decomposability, and high burst resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

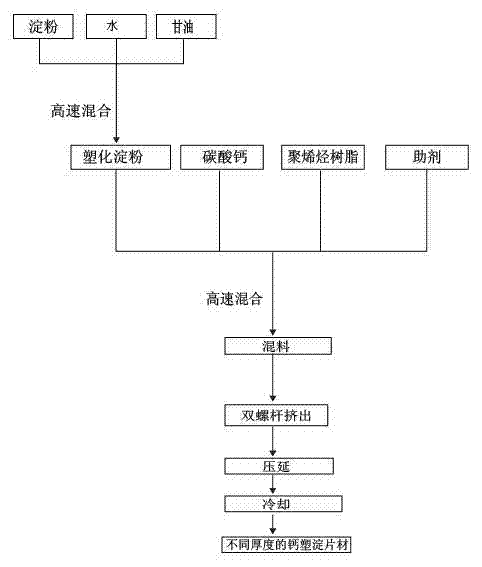

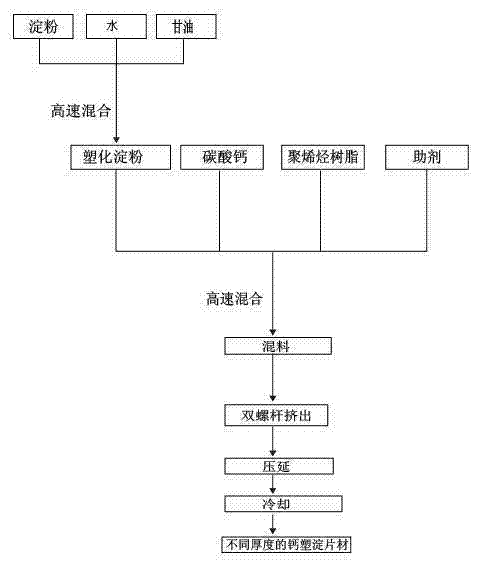

[0023] refer to figure 1 , mix starch, glycerin and water in a weight ratio of 1:1:1, and stir in a high-speed mixer at a temperature of 150°C for 0.5 hours to obtain plasticized starch. Add plasticized starch, HDPE resin, and calcium carbonate in a weight ratio of 1:1:2, add 1wt% antioxidant 1010, 1wt% titanate coupling agent, 1wt% stabilizer, 1wt% degradation accelerator, 1wt% photosensitizer additives (the weight percentage of additives is based on the total amount of plasticized starch, polyolefin resin and calcium carbonate), etc., are mixed uniformly in a high-speed mixer, and then extruded with a twin-screw under the process conditions of polyethylene resin. It is extruded out of the machine, calendered, and cooled to make bio-photodegradable calcium plastic lake resin sheets of different thicknesses.

Embodiment 2

[0025] refer to figure 1 , put starch, glycerin and water in a high-speed mixer at a weight ratio of 1:1:1, and stir for 1.5 hours at a temperature of 150°C to obtain plasticized starch; plasticized starch, polypropylene resin, calcium carbonate and Mixed at a weight ratio of 1:1:2.2, adding 1wt% antioxidant, 1wt% titanate coupling agent, 1wt% stabilizer, 1wt% degradation accelerator, 1wt% photosensitizer (the weight percentage of the additive is based on The total amount of plasticized starch, polyolefin resin and calcium carbonate) is uniformly mixed in a high-speed mixer, extruded with a twin-screw extruder under the process conditions of polypropylene resin, and then rolled and cooled to make into calcium plastic lake resin sheets of different thicknesses.

Embodiment 3

[0027] refer to figure 1 , put starch, glycerin and water in a high-speed mixer at a weight ratio of 1:1:3, and stir for 1.0 hour at a temperature of 150°C to obtain plasticized starch; plasticized starch, polypropylene resin, calcium carbonate, and Mixing at a weight ratio of 1:1:2, adding 1wt% antioxidant, 1wt% titanate coupling agent, 0.8wt% stabilizer, 1wt% degradation accelerator, 0.7wt% photosensitizer (the weight percentage of the auxiliary agent (Based on the total amount of plasticized starch, polyolefin resin and calcium carbonate) etc. are uniformly mixed in a high-speed mixer, then extruded with a twin-screw extruder under the technological conditions of polypropylene resin, and then calendered, Cool and make calcium plastic lake resin sheets of different thicknesses.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com