Double-vacuum annealing device and process for improving magnetic property of soft magnetic material

A soft magnetic material and annealing device technology, applied in the field of metal soft magnetic materials and soft magnetic materials, can solve problems such as variation, achieve excellent mechanical properties, excellent corrosion resistance, and improve magnetic properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

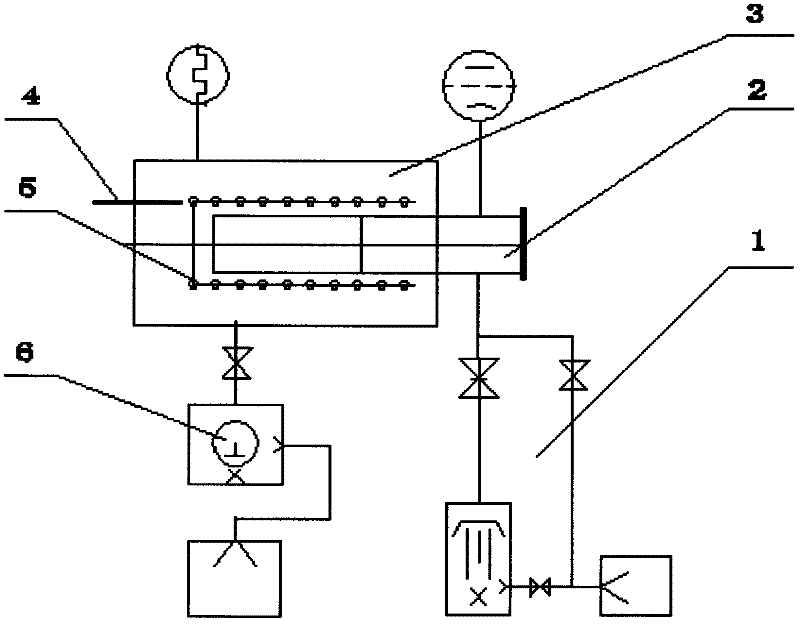

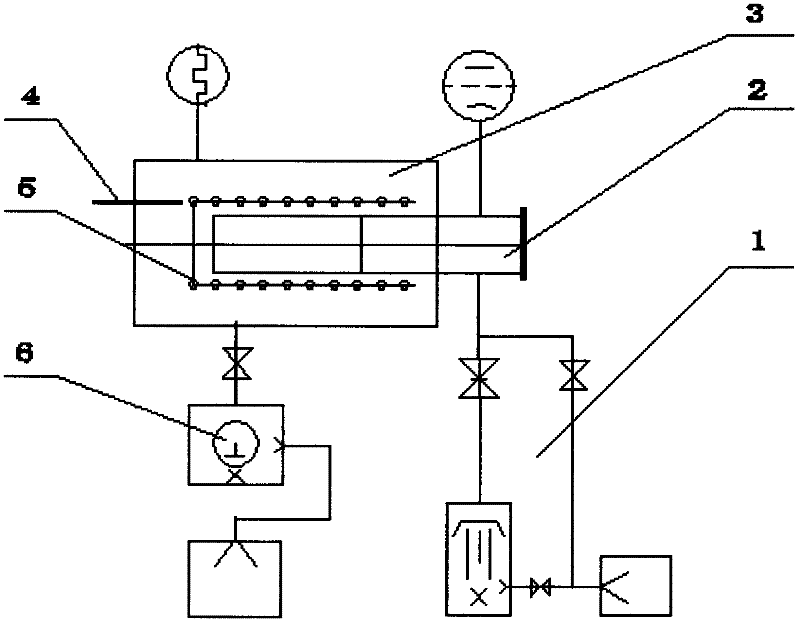

[0027] The present invention will be further elaborated below in conjunction with accompanying drawing and specific embodiment:

[0028] see figure 1 , a double vacuum annealing device for improving the magnetic properties of soft magnetic materials, which includes: a first vacuum furnace chamber 2 as a main chamber, which houses annealing elements; a second vacuum furnace chamber 3 as an auxiliary chamber, It is set outside the first vacuum furnace cavity; a thermocouple 4 is set in the second vacuum furnace cavity; a heating device 5 is set inside the second vacuum furnace cavity and is set on the outer wall of the first vacuum furnace cavity Above, the electric heating device adopts electric heating wire; a Roots pump unit 6, which is connected to the second vacuum furnace chamber; a diffusion pump unit 1, which is connected to the first vacuum furnace chamber, and the annealing element is placed in the main chamber , can pass through the gas of different media.

[0029] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com