Method for dyeing wool quickly at low temperature

A rapid dyeing and wool technology, applied in the field of wool dyeing, can solve the problems of large damage to wool fiber, failure to meet the requirements of manufacturers, high temperature, etc., and achieve the effect of retaining inherent characteristics, good economic and social benefits, and improving gloss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

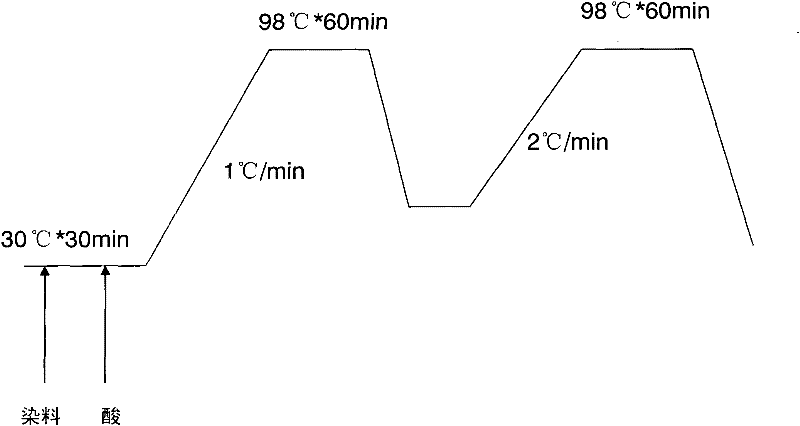

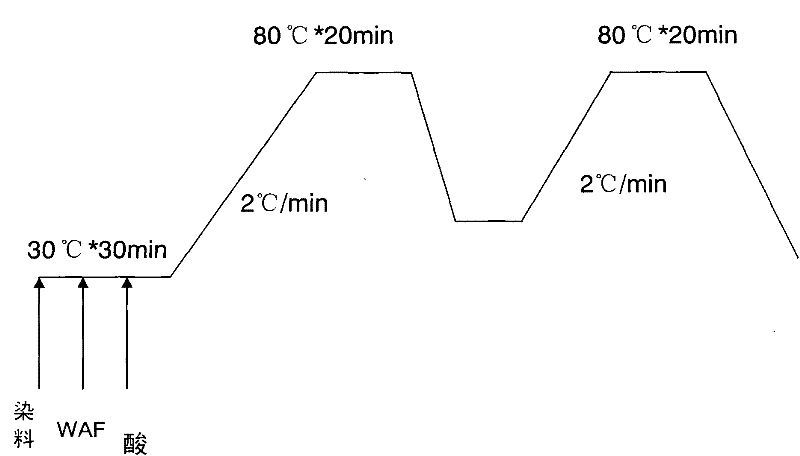

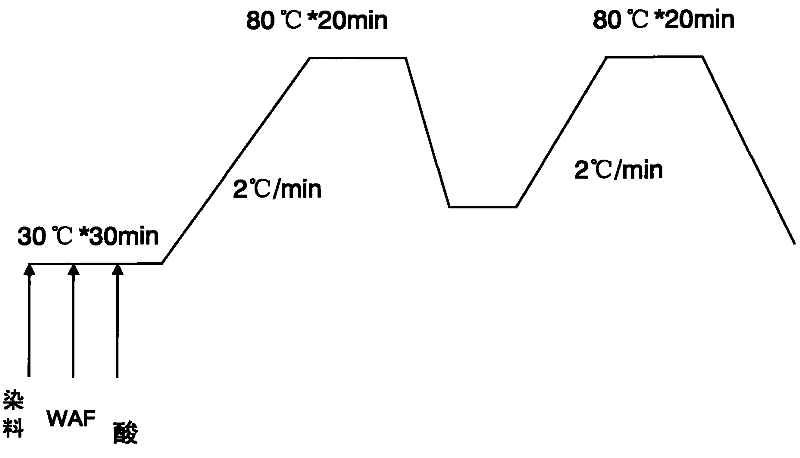

Method used

Image

Examples

Embodiment 1

[0025] The low-temperature and rapid dyeing method of wool of the present invention includes: preparation of leveling agent, preparation of dye solution and low-temperature dyeing of wool, wherein:

[0026] 1) The leveling agent is made of raw materials with the following weight ratios:

[0027] Take 15 kilograms of sodium acetate; 25 kilograms of sodium aromatic polyether benzene sulfonate, 5 kilograms of sodium bisulfite, 15 kilograms of n-pentanol, and 1,000 kilograms of water;

[0028] The preparation steps are as follows:

[0029] Weigh the sodium acetate according to the formula ratio and add it to the water to dissolve and stir evenly, adjust the pH to 4.5 with glacial acetic acid, and then add aromatic polyether benzene sulfonate, sodium bisulfite, n-pentanol, and then homogenize in a constant temperature oscillator Stir for 30min for use;

[0030] 2) The dye solution is made of raw materials with the following weight ratios:

[0031] Dye: 2 kg, levelling agent: 1 kg, water 1000...

Embodiment 2

[0038] The low-temperature and rapid dyeing method of wool of the present invention includes: preparation of leveling agent, preparation of dye solution and low-temperature dyeing of wool, wherein:

[0039] 1) The leveling agent is made of raw materials with the following weight ratios:

[0040] Take 25 kilograms of sodium acetate; 35 kilograms of aromatic polyether benzene sulfonate sodium, 15 kilograms of sodium bisulfite, 25 kilograms of n-pentanol, and 1,000 kilograms of water;

[0041] The preparation steps are the same as in Example 1.

[0042] 2) The dye solution is made of raw materials with the following weight ratios:

[0043] Dye: 8 kg, levelling agent: 5 kg, water 1000 kg;

[0044] Dyes include:

[0045] The preparation steps are the same as in Example 1.

[0046] 3) The low-temperature dyeing procedure of wool is the same as in Example 1.

Embodiment 3

[0048] 1) The leveling agent is made of raw materials with the following weight ratios:

[0049] Take 20 kilograms of sodium acetate; 28 kilograms of sodium aromatic polyether benzene sulfonate, 8 kilograms of sodium bisulfite, 18 kilograms of n-pentanol, and 1000 kilograms of water; the preparation steps are the same as in Example 1.

[0050] 2) The dye solution is made of raw materials with the following weight ratios:

[0051] Dye: 3 kg, leveling agent: 1.5 kg, 1000 kg water; the preparation steps are the same as in Example 1.

[0052] Dyes include:

[0053] 3) The low-temperature dyeing procedure of wool is the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com