Composite phase change heat exchange device for boiler flue gas waste heat recovery

A composite phase conversion heat and waste heat recovery technology, which is applied in the field of equipment in the field of boiler heat transfer technology, can solve problems such as difficulties in the evaporation section of heat exchange circular tubes, achieve flexible adjustment methods, reduce failure rates, and ensure safe operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

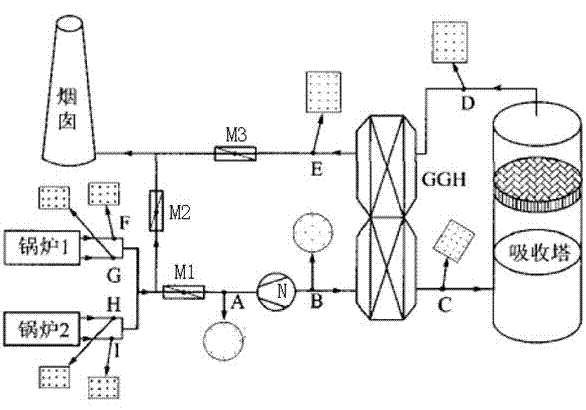

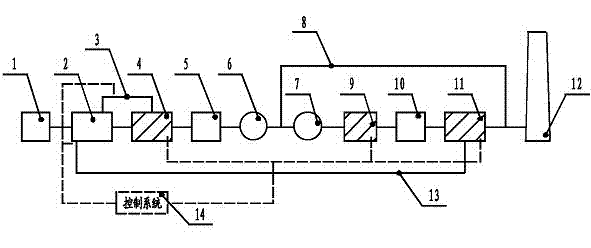

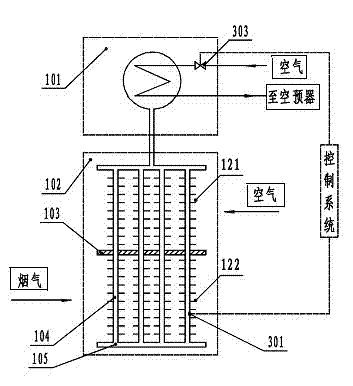

[0060] Composite phase conversion heat device for waste heat recovery of boiler flue gas (see attached Figure 5 and accompanying drawings), using air as the working medium for recycling waste heat, including the boiler flue, internal and external equipment of the flue, its connecting pipes, and control instrument valves. The flue is equipped with a class I composite phase change heat exchanger 24, a stage II composite phase change heat exchanger 29, a supporting control system, a mixing chamber 31, and the boiler’s original economizer 22 and air preheater 23. Dust collector 26, desulfurization tower 30, etc. Outside the flue, a Class I temperature regulation system 35, a Class II temperature regulation system 40, a Class I pump 33, a heat exchanger 34, a Class II pump 39, and matching automatic control devices 36, supporting pipes, instrument valves, etc. are arranged. Part of the hot air 42 from the air preheater 23 flows out, and is sent to the mixing chamber 31 through th...

Embodiment 2

[0079] Composite phase conversion heat device for waste heat recovery of boiler flue gas (see attached Image 6 and description of the accompanying drawings), the device is also provided with a box 24-6 between the tube sheets in the I-stage composite phase-change heat exchanger 24; the II-stage composite phase-change heat exchanger is also provided with a box 29 between the tube sheets -6. This structure is suitable for flue gas in the tube side of the inner heat exchange tube, phase change working fluid in the casing side, and the cold fluid in the shell layer is liquid. For the shell side, the cold fluid 37 such as water, heat transfer oil or other suitable process medium is used as the medium for waste heat recovery. See Embodiment 1 for other specific implementation methods.

Embodiment 3

[0081] Composite phase conversion heat device for waste heat recovery of boiler flue gas (see attached Figure 7 and accompanying drawings), for boilers without desulfurization devices, the second-stage composite phase change heat exchanger 29 is used to continue to recover the waste heat of the flue gas. Since dew condensation may occur, a mixing chamber 31 is still installed and heated by the air preheater Part of the hot air 42 flows out from the hot air pipe 42-1 to the mixing chamber 31, where it is uniformly mixed with the outlet flue gas of the second-stage composite phase change heat exchanger 29 to avoid condensation, and then discharged into the air through the chimney. atmosphere. Refer to Embodiment 1 or Embodiment 2 for other specific implementation methods.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com