Reverse osmosis membrane scale inhibitor and application thereof

A technology of reverse osmosis membrane and scale inhibitor, which is applied to the reverse osmosis membrane scale inhibitor and its application field in the reverse osmosis water treatment process, can solve the problem that the scale inhibitor is difficult to meet the needs of production, and achieve stable CaCO3 , the effect of improving work efficiency and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

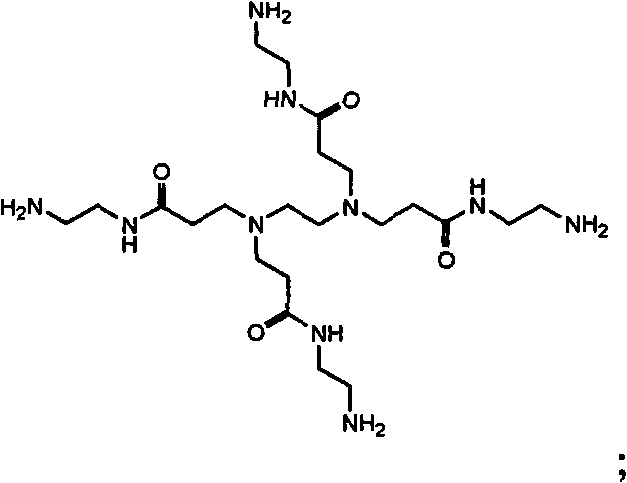

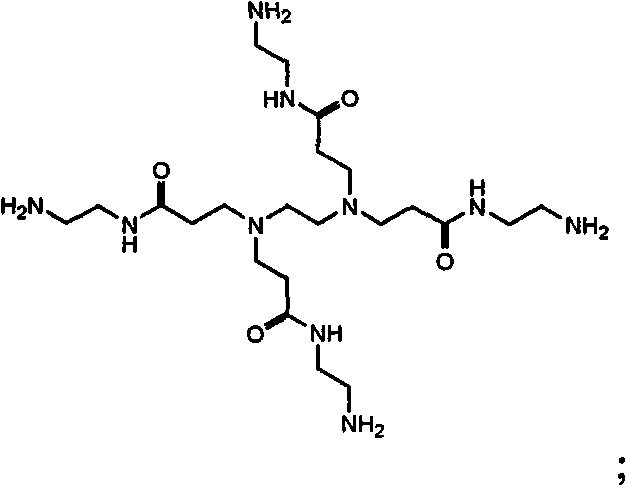

Embodiment 1

[0055] Weigh 20g of dendrimers, the limiting viscosity is 0.07dL g -1 (measured at 30°C, the same below), 6.67g of acrylic acid / acrylamide copolymer (the mass ratio of acrylic acid / acrylamide is 2:1) with a solid content of 30%, 8g of hydroxyethylidene diphosphonic acid with a solid content of 50% , dissolved in 5.33g of water, made into antiscalant 1 for reverse osmosis membrane. Dosing reverse osmosis membrane antiscalant 1 in test water 2, the dosing concentration is 40mg·L -1 . The effective concentration of dendrimers is 20mg L -1 , the effective concentration of acrylic acid / acrylamide copolymer is 2mg·L -1 , the effective concentration of hydroxyethylidene diphosphonic acid is 4mg·L -1 .

Embodiment 2

[0057] Weigh 30g of dendrimers, the limiting viscosity is 0.07dL g -1 10g of acrylic acid / acrylamide copolymer (the mass ratio of acrylic acid / acrylamide is 2:1) with a solid content of 30%, 2-phosphonic acid group-1,2,4-tricarboxylic acid butyl with a solid content of 50% Alkanes 6g, dissolved in 4g of water, made into reverse osmosis membrane scale inhibitor 2. Dosing reverse osmosis membrane antiscalant 2 in test water 2, the dosing concentration is 50mg·L -1 . The effective concentration of dendrimers is 30mg L -1 , the effective concentration of acrylic acid / acrylamide copolymer is 3mg·L -1 , The effective concentration of 2-phosphono-1,2,4-tricarboxylic acid butane is 3mg L -1 .

Embodiment 3

[0059] Weigh 40g of dendrimers, the limiting viscosity is 0.07dL g -1 13.33g of acrylic acid / acrylamide copolymer (the mass ratio of acrylic acid / acrylamide is 2:1) with a solid content of 30%, 4g of polyether-based polyaminomethylene phosphonic acid with a solid content of 50%, dissolved in 2.67 g water, made into reverse osmosis membrane antiscalant 3. Dosing reverse osmosis membrane antiscalant 3 in test water 1, the dosing concentration is 60mg·L -1 . The effective concentration of dendrimers is 40mg L -1 , the effective concentration of acrylic acid / acrylamide copolymer is 4mg·L -1 , the effective concentration of polyether-based polyaminomethylenephosphonic acid is 2mg·L -1 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| scale inhibition rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com