Low-lead anti-corrosion forging yellow brass alloy and manufacturing method thereof

A technology of brass alloy and manufacturing method, applied in the field of bar and low-lead brass alloy tube, can solve the problems of limited tin corrosion resistance, high cost of bismuth brass raw materials, inability to pass, etc., and achieve excellent corrosion resistance, The effect of low harm to human body and environment and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

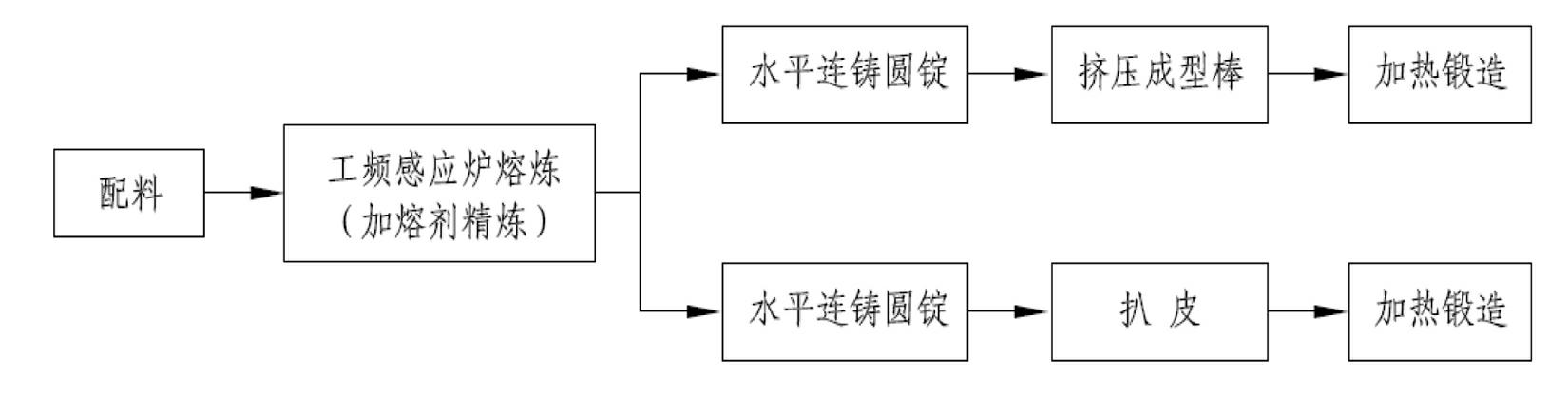

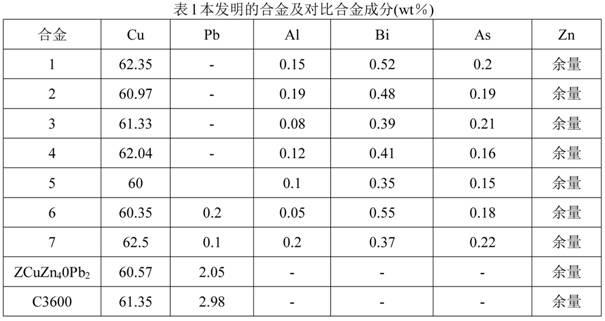

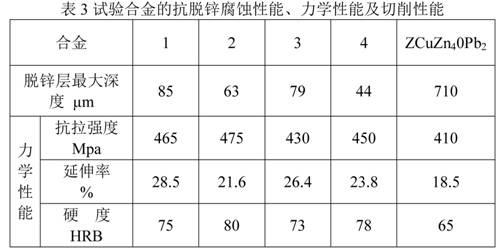

[0018] The composition of the brass alloy of the present invention and the alloy composition used for comparative research are listed in Table 1, wherein, alloys 1 to 2 are used for horizontal continuous casting ingots, extruded into rods and then hot forged, and the preparation process is as shown in Figure 1 , batching, smelting, horizontal continuous casting of round ingots, extrusion and heating forging, wherein the temperature of the horizontal continuous casting is 990-1060°C, the temperature of the extrusion is 650-760°C, and the temperature of the heating forging is 650~760℃.

[0019] Alloys 3-7 are used for hot forging of horizontal continuous casting rods. The preparation process is shown in Figure 1, batching, smelting, horizontal continuous casting rods, peeling and heating forging, wherein the temperature of the horizontal continuous casting is 990-1060 ° C, The temperature of the heating forging is 650-760°C.

[0020] Alloy ZCuZn 4 0Pb 2 , C3600 is a comparati...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap