Dewatered sludge solidifying agent

A curing agent and sludge technology, applied in the direction of dehydration/drying/concentrated sludge treatment, etc., can solve the problems of large engineering volume, secondary pollution, high cost, etc., to improve adsorption performance, improve particle size ratio, and reduce voids rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] First prepare the dewatered sludge curing agent: its components include Portland cement, modified fly ash, fine sand, calcium sulfate; wherein the quality of modified fly ash is 7% of the quality of Portland cement, and the quality of fine sand It is 3% of Portland cement quality, and particle diameter is 0.63~1.25mm, and the quality of calcium sulfate is 1.4% of Portland cement quality; The preparation method of described modified fly ash is: fly ash at 280 Bake at ℃ for 70 minutes, and keep sealed before use.

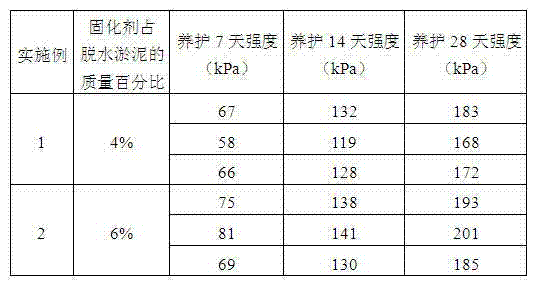

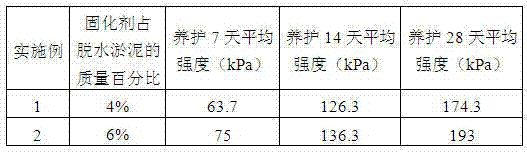

[0023] Take 1 kg of the dewatered sludge solidifying agent prepared above and add it to 25 kg of dehydrated sludge. The mass percentage of the solidifying agent in the dehydrated sludge is 4%, and the water content of the dehydrated sludge is 40%. Stir the mixture evenly, and prepare three sets of standard models, which are cylindrical, with a diameter of 3.9 cm and a height of 8 cm. These three groups of models were respectively cured at room temperature for ...

Embodiment 2

[0025] First prepare the dewatered sludge curing agent: its components include Portland cement, modified fly ash, fine sand, calcium sulfate; wherein the quality of modified fly ash is 5% of the quality of Portland cement, and the quality of fine sand It is 1% of the quality of Portland cement, the particle size is 0.63 ~ 1.25mm, and the quality of calcium sulfate is 1% of the quality of Portland cement; the preparation method of the modified fly ash is as follows: fly ash at 320 Bake at ℃ for 45 minutes, and keep sealed before use.

[0026] Take 1 kg of the dewatered sludge solidifying agent prepared above and add it to 16.7 kg of dehydrated sludge. The mass percentage of the solidifying agent in the dehydrated sludge is 6%, and the water content of the dehydrated sludge is 50%. Stir the mixture evenly, and prepare three sets of standard molds. The molds are cylindrical, with a diameter of 3.9 cm and a height of 8 cm. These three groups of models were respectively cured at r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com