Tunnel bituminous pavement light color functional layer based on light color cement material

A technology of bright-colored binder and asphalt pavement, which is applied in the field of paving materials and structures, can solve problems such as difficult to meet the requirements of tunnel use, dark appearance, low bond strength, etc., and achieve excellent structural integrity and road surface functionality , enhance the lighting level, improve the effect of adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

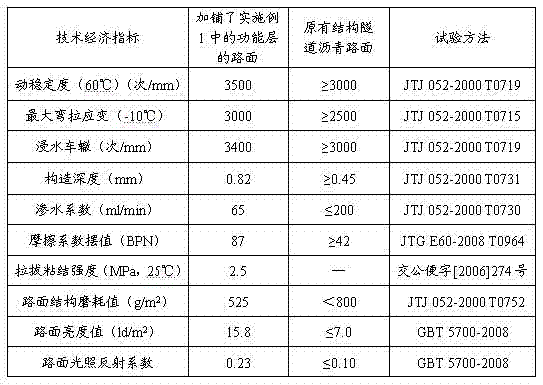

Embodiment 1

[0033] A clear colorized functional layer of tunnel asphalt pavement based on clear color cement, which includes clear color cement material and crushed stone material; among them, the clear color cement material consists of the following A component and B component according to the mass ratio It is a 1:1 mixture, and the percentage of each substance is calculated according to the mass percentage of the component:

[0034] A component:

[0035] 40% methyl methacrylate, 10% hydroxyethyl methacrylate

[0036] Butyl methacrylate 10%, calcium carbonate 20%,

[0037] N,N-dimethyl-p-toluidine 5%, titanium dioxide 10%, fumed silica 5%;

[0038] B component:

[0039] Methyl methacrylate 30%, hydroxyethyl methacrylate 10%

[0040] 20% butyl methacrylate, 20% calcium carbonate,

[0041] Dibenzoyl peroxide 5%, titanium dioxide 10%, fumed silica 5%.

[0042] Among them, the gravel material is basalt, which has a certain angularity and gradation. The particle size of the gravel is 1~3mm, and the cover...

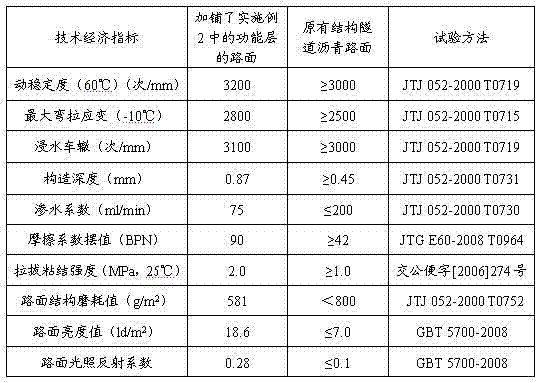

Embodiment 2

[0049] A clear colorized functional layer of tunnel asphalt pavement based on clear color cement, which includes clear color cement material and crushed stone material; among them, the clear color cement material consists of the following A component and B component according to the mass ratio It is a 1:1 mixture, and the percentage of each substance is calculated according to the mass percentage of the component:

[0050] A component:

[0051] 20% methyl methacrylate, 30% hydroxyethyl methacrylate

[0052] Butyl methacrylate 10%, calcium carbonate 32.5%,

[0053] N,N-dimethyl-p-toluidine 2%, titanium dioxide 5%, fumed silica 0.5%;

[0054] B component:

[0055] Methyl methacrylate 20.5%, Hydroxyethyl methacrylate 22%

[0056] Butyl methacrylate 10%, calcium carbonate 40%,

[0057] Dibenzoyl peroxide 2%, titanium dioxide 5%, fumed silica 0.5%.

[0058] Among them, the gravel material is limestone, which has a certain angularity and gradation. The particle size of the gravel is 1~3mm, and ...

Embodiment 3

[0065] A clear colorized functional layer of tunnel asphalt pavement based on clear color cement, which includes clear color cement material and crushed stone material; among them, the clear color cement material consists of the following A component and B component according to the mass ratio It is a 1:1 mixture, and the percentage of each substance is calculated according to the mass percentage of the component:

[0066] A component:

[0067] Methyl methacrylate 30%, hydroxyethyl methacrylate 20%

[0068] 20% butyl methacrylate, 20% calcium carbonate,

[0069] N,N-dimethyl-p-toluidine 1%, titanium dioxide 8%, fumed silica 1%;

[0070] B component:

[0071] 35% methyl methacrylate, 15% hydroxyethyl methacrylate

[0072] Butyl methacrylate 10%, calcium carbonate 30%,

[0073] Dibenzoyl peroxide 1%, titanium dioxide 8%, fumed silica 1%.

[0074] Among them, the gravel material is lime greenstone, which has certain angularity and gradation. The gravel particle size is 1~3mm, and the coverag...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| cover factor | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com