Composite heat insulating material and preparation method thereof

A technology of composite thermal insulation materials and thermal insulation materials, applied in thermal insulation, building components, fire protection, etc., can solve problems such as leakage, poor construction quality, and low strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

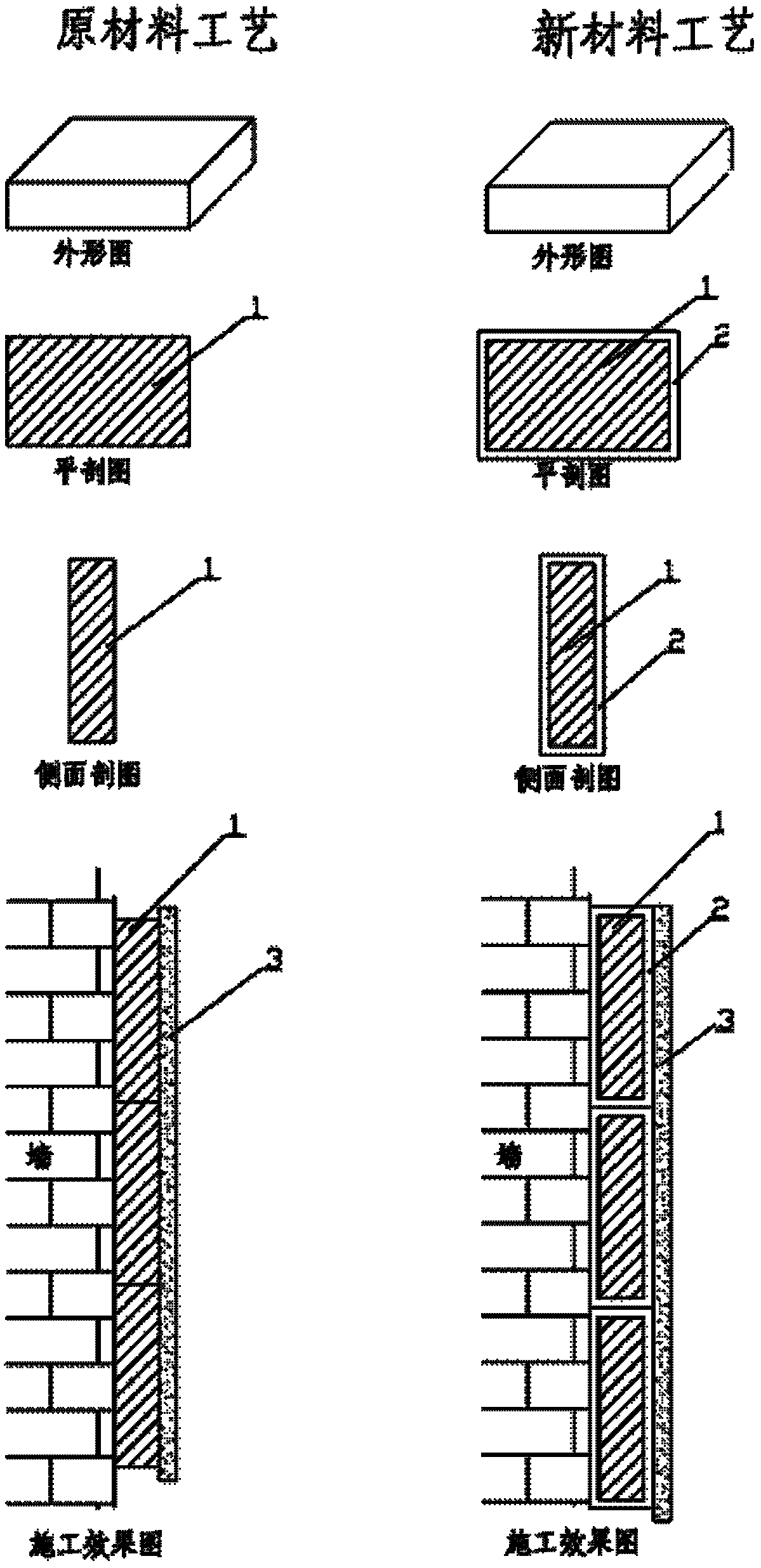

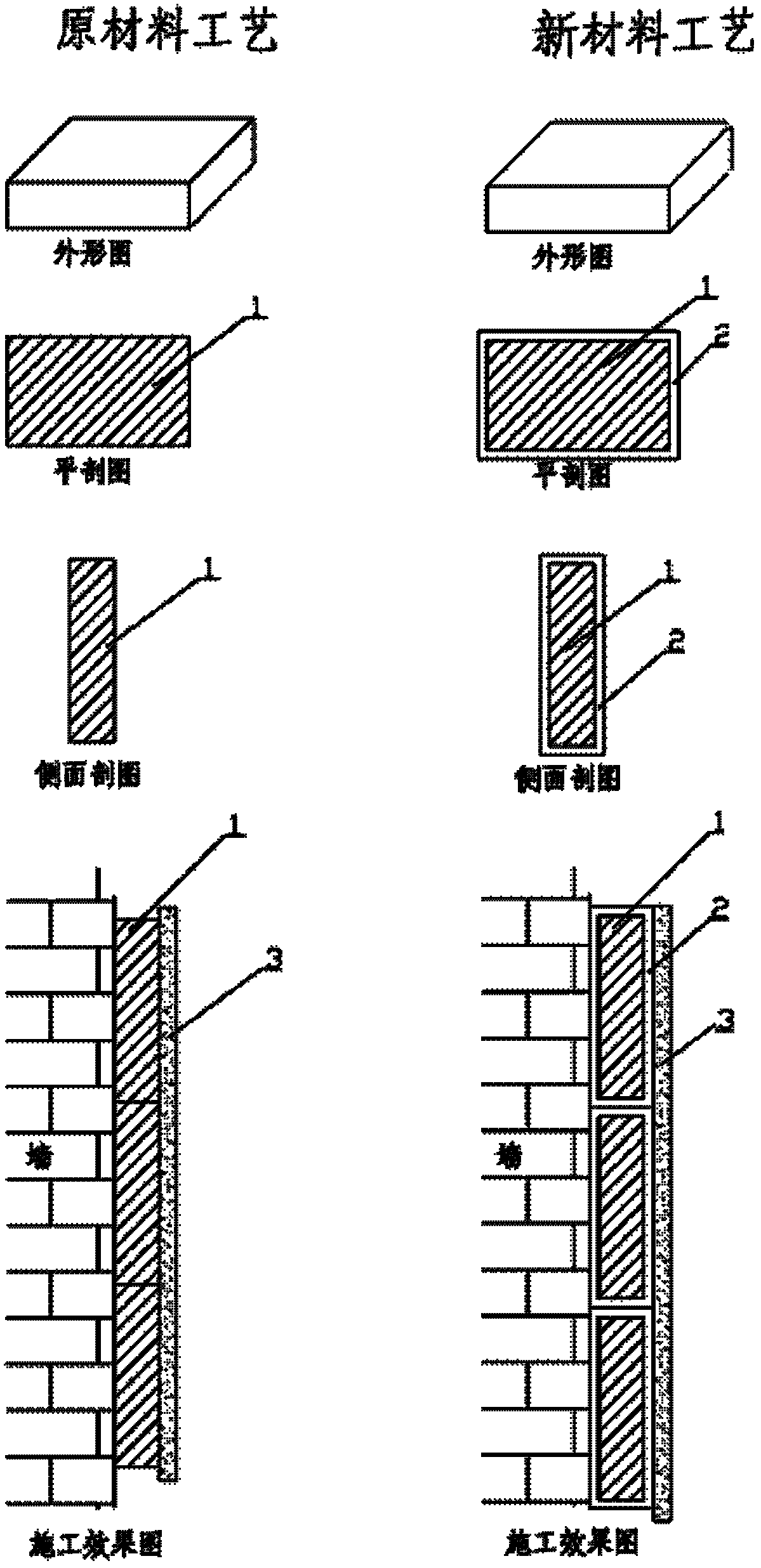

[0011] As shown in Figure 1 is the comparative figure of composite thermal insulation board of the present invention and existing thermal insulation board, and among Fig. 1, 1 is organic thermal insulation material, and 2 is the fireproof material as protective isolation layer, and 3 is exterior wall covering mortar. From the side sectional view and plan sectional view, it can be seen that the new material has an additional protective barrier than the old material. From the construction renderings, it can be seen that the organic insulation materials of the old material are connected into a large piece, while the new material has one by one. The fireproof layer 2 is disconnected to form fireproof units one by one. If the outer wall covering mortar 3 falls off, the old material will be exposed to the organic thermal insulation material 1, and will catch fire when encountering an open flame. Even if the outer wall covering mortar of the new material falls off, the organic thermal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com