Electric connector and manufacturing method thereof

A technology of electrical connectors and manufacturing methods, which is applied in the field of high-density electrical connectors and its manufacturing, can solve the problems of weak circuit board strength, large thickness, and inability to meet electrical connectors, so as to avoid insertion force and solve difficult folding , the effect of small thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

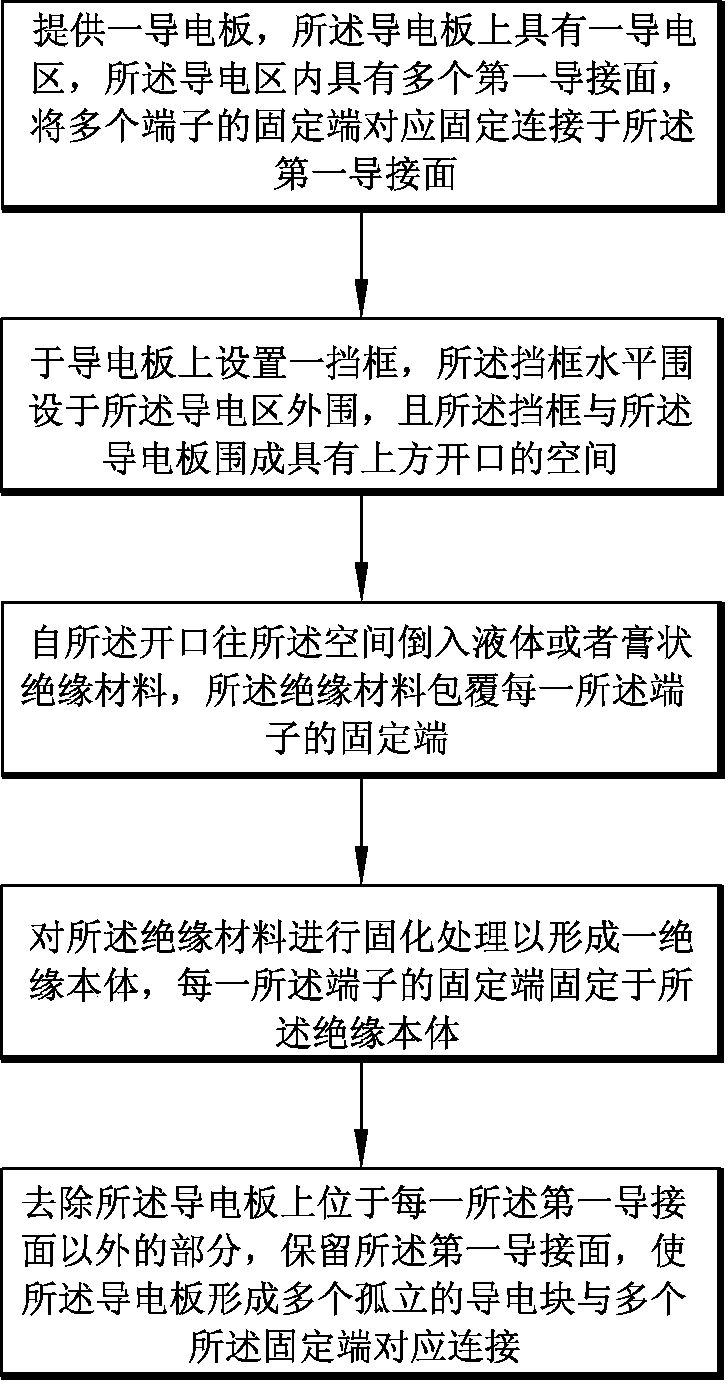

[0041] refer to figure 1 The process in the present invention provides a method for manufacturing an electrical connector, comprising the following steps:

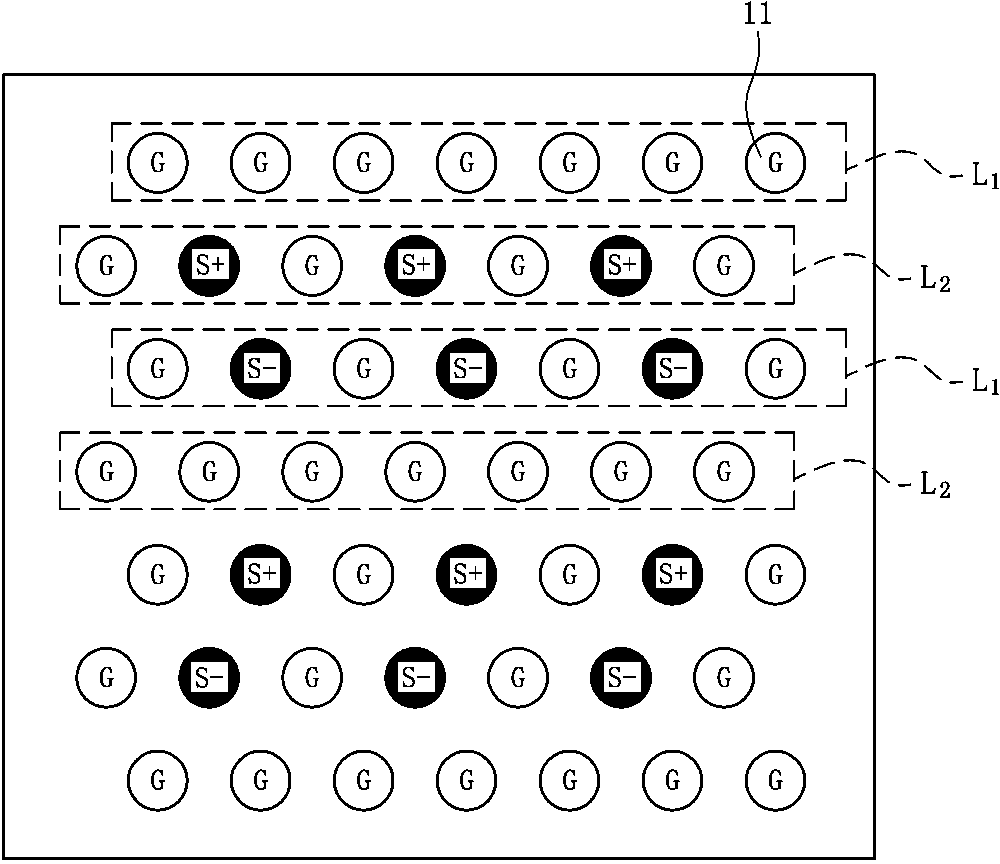

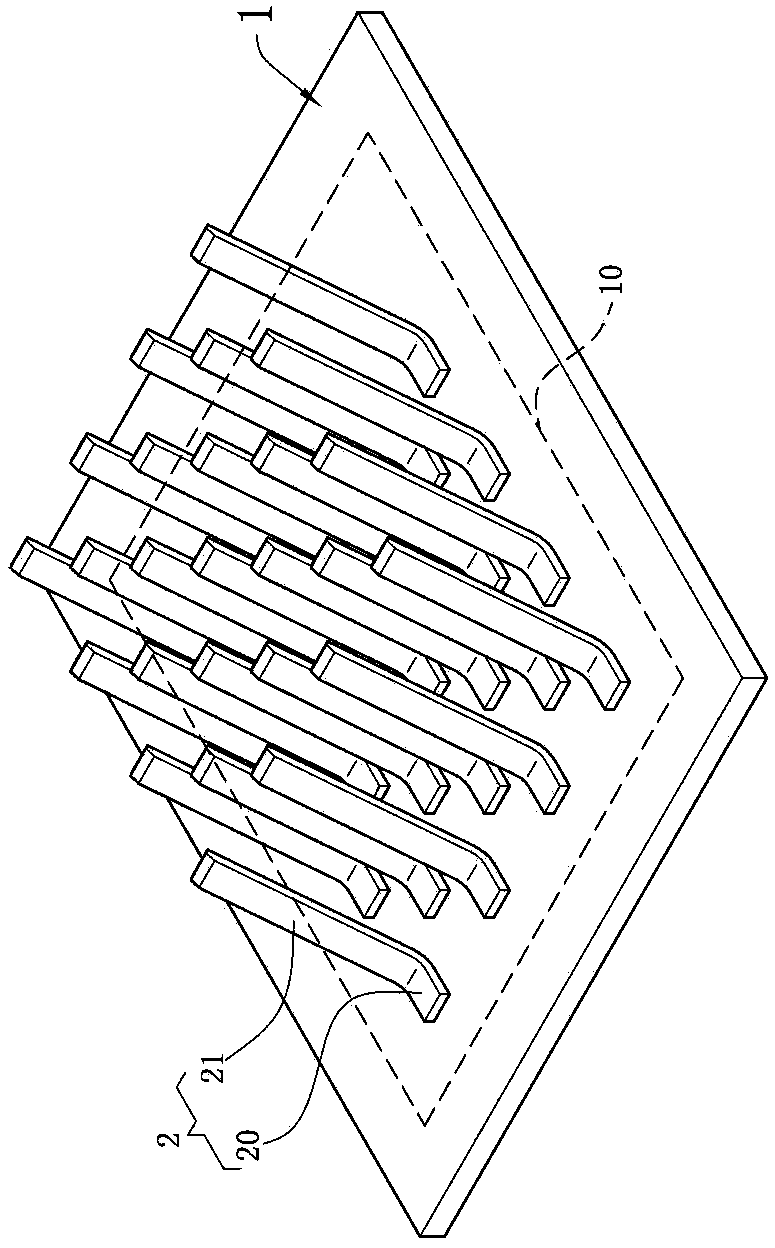

[0042] Firstly, a conductive plate 1 and a plurality of terminals 2 are provided. The conductive plate 1 used in the present invention can be selected from materials such as high-temperature-resistant metals (such as copper, iron, etc.) or non-metals (such as graphite, silicon, etc.), the melting point of which is much higher than that of solder (usually used tin ball), in this embodiment, considering factors such as price, electrical performance and mechanical performance, brass is preferably used as the conductive plate 1 . like figure 2 and image 3 As shown in , a conductive area 10 is defined on the conductive plate 1, and a plurality of first conductive surfaces 11 are arranged in a honeycomb shape in the conductive area 10; the terminal 2 is linear and has a fixed end 20 and an elastic arm 21, the fixed end 20...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com