Solar cell and method of producing same

A solar cell and back electrode technology, applied in the direction of electrical components, final product manufacturing, sustainable manufacturing/processing, etc., can solve the problems of insufficient conversion efficiency, achieve strong and excellent conversion efficiency, prevent electrode peeling, and conduct electricity excellent effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

[0031] Next, embodiments of the present invention will be described using the drawings. In the following description of the drawings, the same or similar symbols are attached to the same or similar parts. However, it should be noted that the drawings are only schematic diagrams, and ratios of dimensions and the like are different from actual ones. Therefore, specific dimensions and the like should be judged in consideration of the following description. In addition, it is needless to say that the relationship and ratio of mutual dimensions are different between drawings.

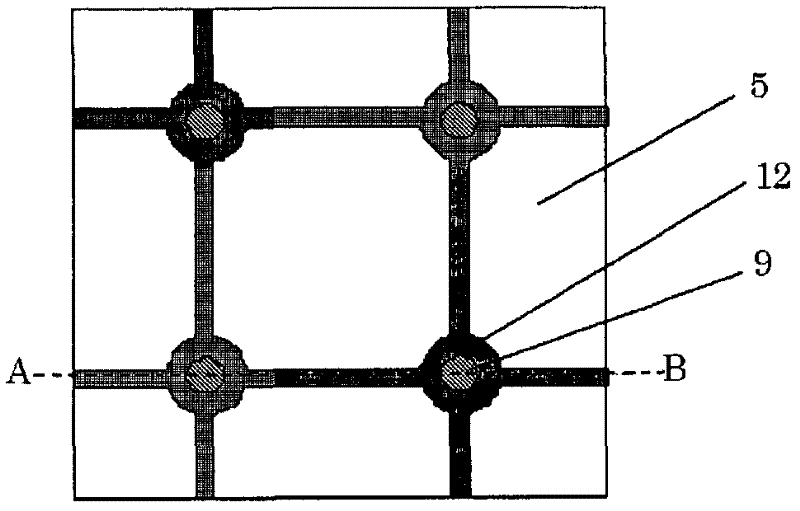

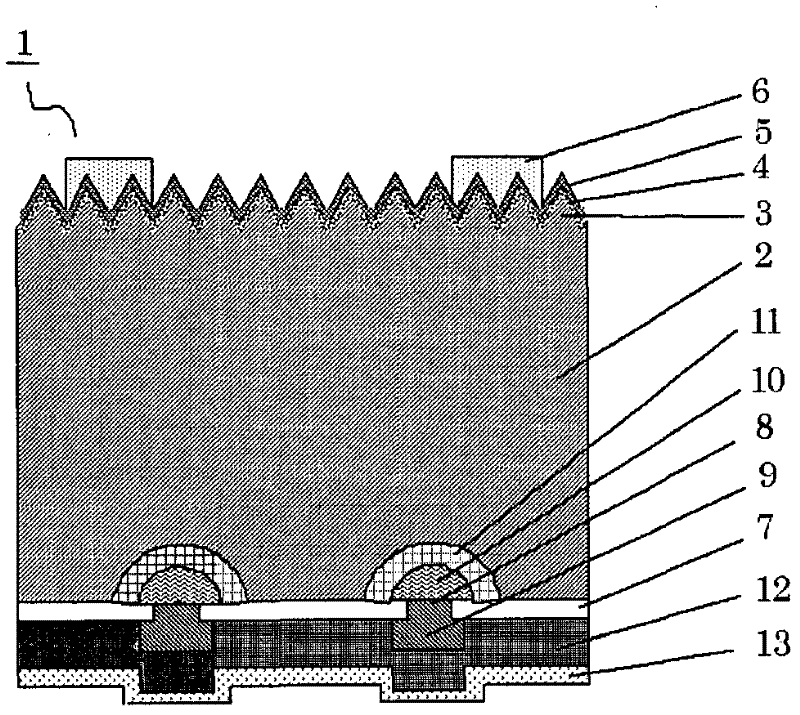

[0032] figure 1 It is a perspective view of a part of the solar battery cell in Embodiment 1 of the present invention seen from the back side (the back side lower layer electrode is shown). in addition, figure 2 is along figure 1 It is a cross-sectional view when A-B shown is cut.

[0033] In the figure, a solar battery unit 1 includes a silicon substrate 2 composed of p-type single crystal or polycry...

Embodiment approach 2

[0051] Figure 14 It is a perspective view of a part of the solar battery cell in Embodiment 2 of the present invention seen from the back side (showing the back side lower layer electrode). In Embodiment 1 above, the case where the aluminum electrode 9 is in the form of dots has been described, but in the solar battery cell with the rear passivation structure of the present invention, if the opening area is reduced in polysilicon, the silicon will be dissipated due to the grain boundary. The response changes and the contact state is unstable, so there is a possibility that sufficient characteristics cannot be obtained.

[0052] Therefore, in the solar battery cell 1 according to Embodiment 2 of the present invention, the shape of the opening to the passivation film 7 and the electrode shape of the aluminum electrode 9 as the first back electrode make it possible to pass through the polycrystalline crystal grain boundaries. The strip-shaped electrodes 14 are configured in a s...

Embodiment approach 3

[0062] In Embodiment 1 described above, the Al-Si paste containing aluminum particles and silicon particles was printed superimposedly on the basis of forming the aluminum electrode to form the Al-Si electrode as the second back electrode, but it is also possible to use aluminum and For the Al—Si alloy obtained by melting silicon, a paste made of powder obtained by making the alloy into particles or a paste containing the powder is used.

[0063]The composition ratio of aluminum and silicon in this Al—Si alloy is the same as the mixing ratio in the case of using aluminum particles and silicon particles, and silicon is 5 to 20 parts by weight relative to 100 parts by weight of aluminum.

[0064] In the case of using a powder made of Al-Si alloy, the reactivity to the silicon substrate is slightly lower than the case of using a paste made of a mixed powder of aluminum particles and silicon particles, so the substrate can be Warpage is suppressed to be small.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Surface resistance | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com