Method for preparing low-silicon NaX zeolite by applying activated silicon source

A technology for activating silicon and silicon sources, applied in the direction of crystalline aluminosilicate zeolite, octahedral crystalline aluminosilicate zeolite, etc., which can solve problems such as increased cost, troublesome operation, and slow exchange rate of potassium ions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] The main raw material used: water glass (wherein the active ingredient content is SiO 2 26.79wt%, Na 2 O10.62wt%), sodium aluminate ((wherein the content of active ingredient is Al 2 o 3 43.3 wt%, Na 2 O 40.35wt%), sodium hydroxide (analytically pure, purity 98wt%)

[0017] First prepare the activated silicon source, weigh 1.61 grams of sodium aluminate, add 21.29 grams of deionized water, stir to dissolve, then add 4.55 grams of sodium hydroxide, continue to stir and dissolve. Then this alkaline sodium aluminate solution is slowly added in 26.89 grams of water glass, stirs while adding dropwise, stirs again 30 minutes after finishing adding. It was used after standing and aging at room temperature (25°C) for 1 day. The activated silicon originates from being stored at room temperature for 1 to 7 days and is in a liquid state and is effective. If left for too long, gel will be formed, and the activity will decrease when the gel is formed. If the aging temperature...

Embodiment 2

[0021] The raw materials used are the same as in Example 1, and the preparation and molar composition of the activated silicon source are the same as in Example 1.

[0022] When synthesizing low-silicon NaX zeolite, weigh 2.09 grams of sodium aluminate, add 45.96 grams of water, stir and dissolve, add 0.46 grams of sodium hydroxide, continue to stir and dissolve, and slowly add the prepared alkaline sodium aluminate solution to 10.86 In the above-mentioned activated silicon source, stir while adding, and stir for 30 minutes after adding. Then the reaction mixture was placed in a reaction kettle, statically crystallized at 60°C for 24h, then filtered, washed with deionized water to be close to neutral, and dried at 100°C. The molar ratio of each component in the reaction mixture is Na 2 O:Al 2 o 3 : SiO 2 :H 2 O=4.2:1:2.4:300.

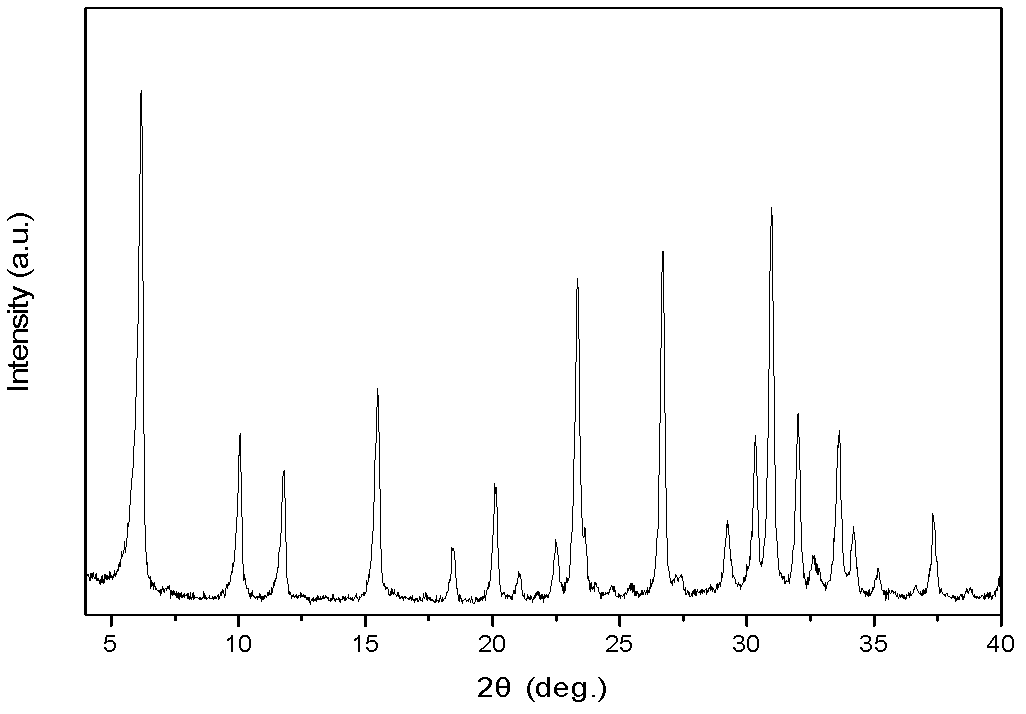

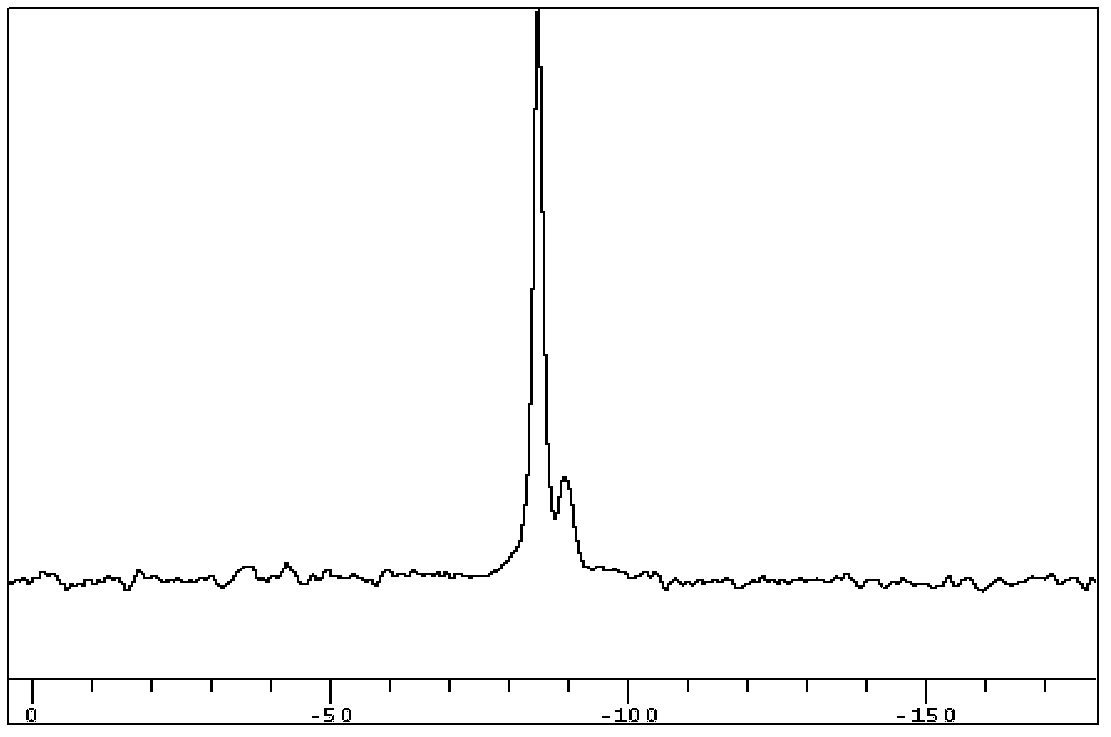

[0023] The product was analyzed as zeolite X using X-ray powder diffraction, solid using magic angle rotation 29 Si-NMR analysis of SiO in the p...

Embodiment 3

[0025] The raw materials used are the same as in Example 1, and the preparation and molar composition of the activated silicon source are the same as in Example 1. The molar ratio and preparation method of the synthetic low-silicon NaX reaction mixture are the same as in Example 2, but the crystallization temperature is different, specifically crystallization at 60°C for 7h, and then crystallization at 95°C for 5h. The molar ratio of each component in the reaction mixture is Na 2 O:Al 2 o 3 : SiO 2 :H 2 O=4.2:1:2.4:300.

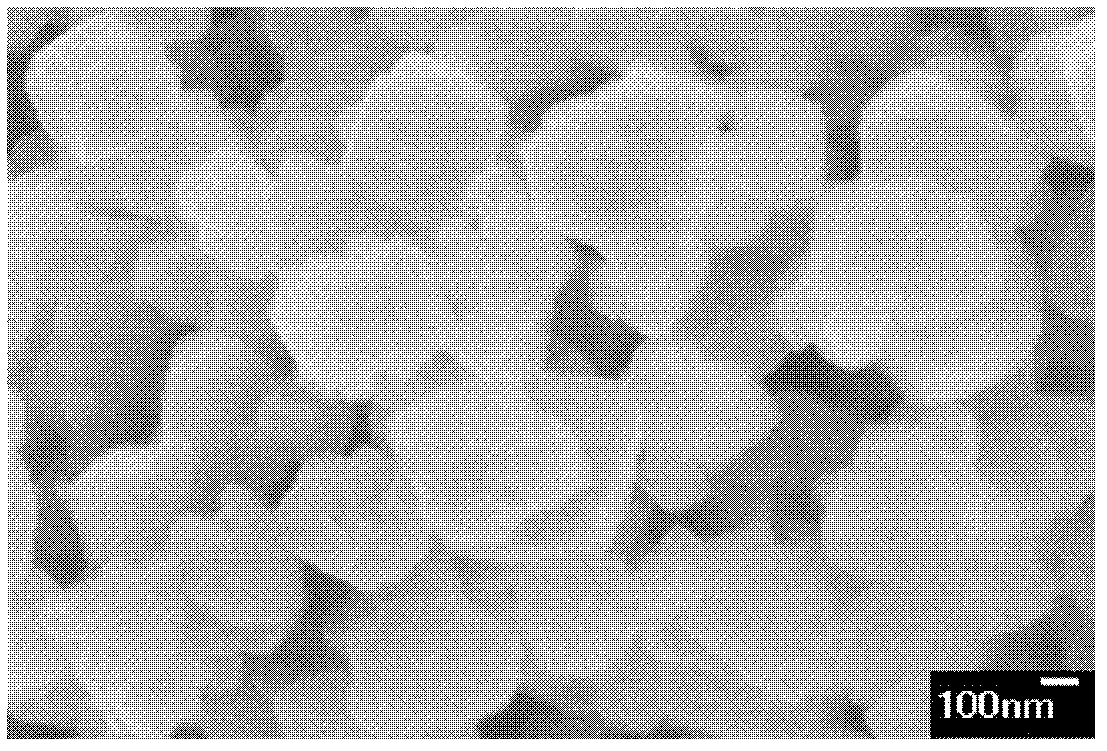

[0026] The product was analyzed as zeolite X using X-ray powder diffraction, solid using magic angle rotation 29 Si-NMR analysis of SiO in the product 2 / Al 2 o 3 The molar ratio is 2.08, and the average particle size is 210nm by scanning electron microscope analysis.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com