Gasification furnace and method for gasifying molded coal

A gasification type and gasification furnace technology, which is applied in the field of coal gasification with fixed bed circulation method, can solve the problems of wall-hanging coal gasification, achieve stable gasification layer height, reduce scouring force, and prevent coal gasification wall-hanging Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

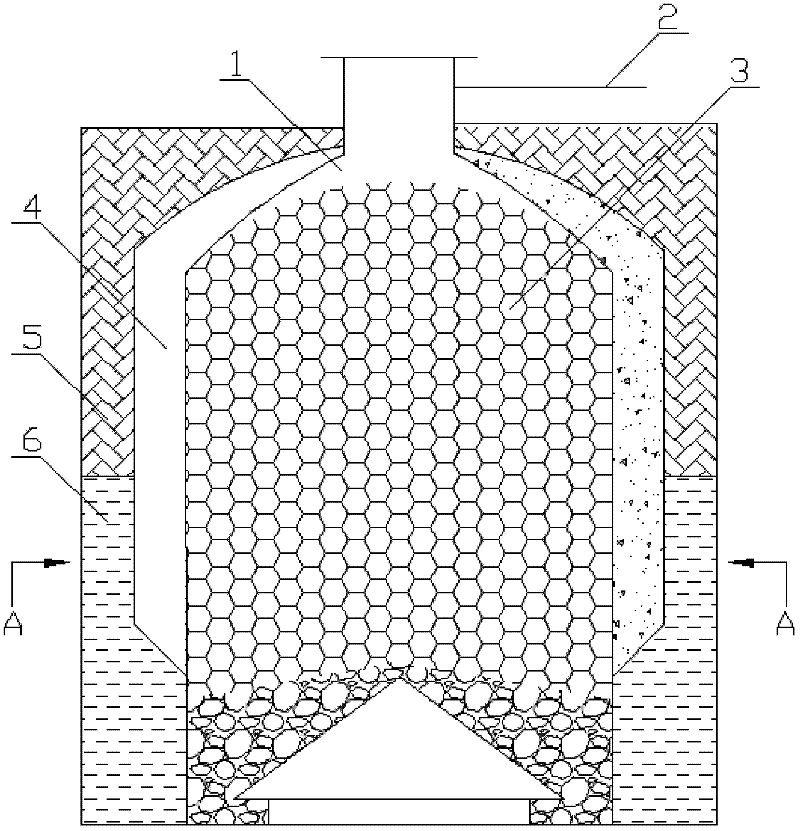

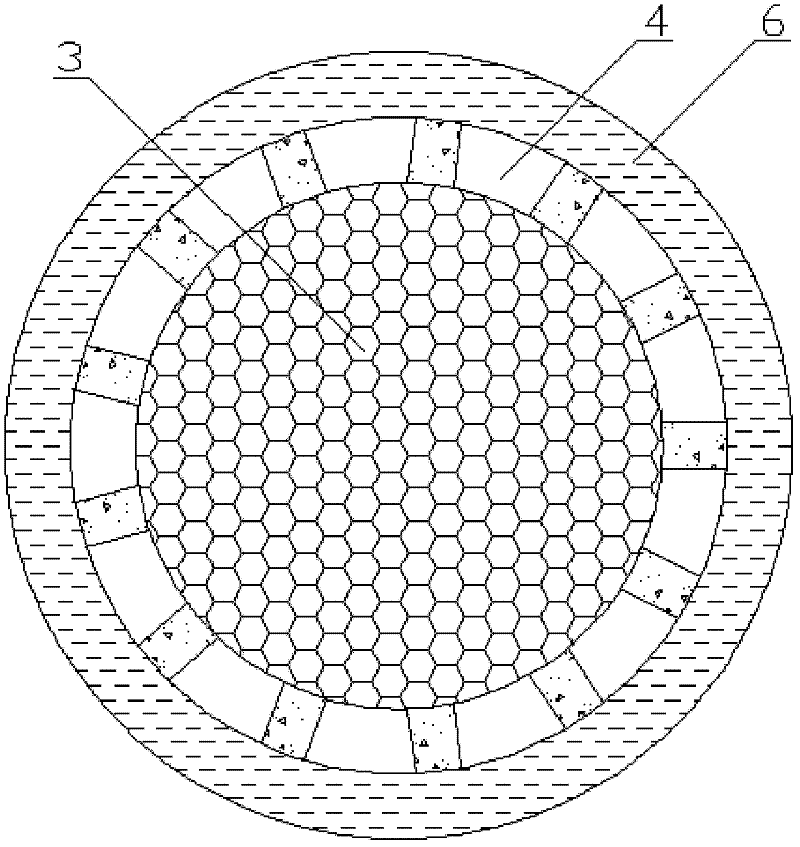

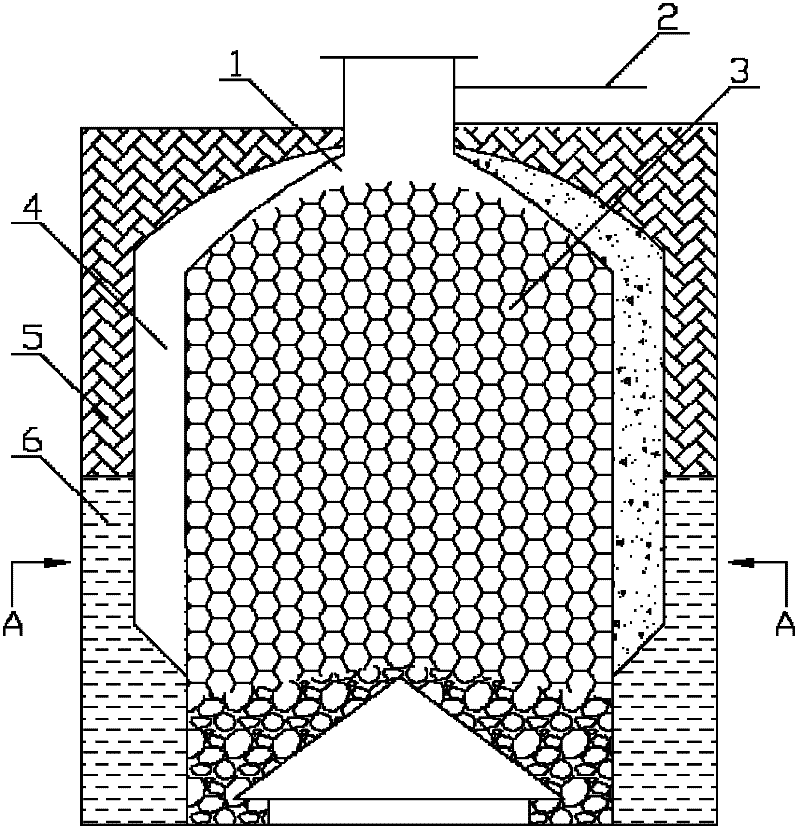

[0016] like figure 1 , figure 2 As shown, the structure of the gasifier of the present invention includes a furnace body. A furnace 1 is arranged in the middle of the furnace body. A charcoal layer 3 is arranged in the furnace. The top of the furnace 1 is provided with an ascending pipeline 2. The furnace body is provided with a refractory wall 5. A water jacket 6 is provided at the bottom of the wall 5, and a plurality of grooves 4 are arranged around the inner wall of the furnace, and the grooves 4 are evenly arranged around the circumference of the furnace.

[0017] The method of the present invention is that the charcoal layer 3 is gasified in the furnace 1, and the inner wall of the furnace 1 is covered with grooves 4, and the grooves 4 can effectively separate the inner wall of the furnace 1 from the outer wall of the charcoal layer 3, forming a large number of grooved upward pipelines ; The high-temperature flame and high-temperature gas sprayed horizontally to each g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com