Method for preparing magnesium alloy

A magnesium alloy and magnesium powder technology, applied in the field of metal materials, can solve problems such as difficult control of Si phase nucleation and growth, influence on the mechanical properties of magnesium alloys, coarse microstructure of heat-resistant magnesium alloys, etc., and achieve fine and uniform microstructure, microscopic The structure is uniform and fine, and the effect of improving the mechanical properties at room temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0023] The embodiment of the present invention discloses a method for preparing a magnesium alloy, comprising the following steps:

[0024] a) Mg 2 Si nano powder, zinc powder, aluminum powder and magnesium powder are high-energy ball milled for 1-2 hours to obtain a mixed powder, which includes: 2.2-3.6 wt% magnesium silicide, 0.5-1.5 wt% zinc, 4.5-5.5 wt% aluminum and 90.5-91.9wt% magnesium;

[0025] b) press-molding the mixed powder to obtain a green body;

[0026] c) heating the green body under the protection of an inert gas at a heating temperature of 420-450° C., keeping it warm for 30-50 minutes, extruding after heating, and water-cooling the extruded green body to obtain the final magnesium alloy.

[0027] In order to obtain fine reinforcement phase particles, the present invention directly adds heat-resistant phase magnesium silicide nano powder, and the magnesium silicide nano powder is obtained by ball milling micron-sized magnesium silicide powder. Compared wit...

Embodiment 1

[0043] a) 4.34 grams of magnesium silicide nano powder, 2 grams of zinc powder, 10 grams of aluminum powder and 183.66 grams of magnesium powder were mixed in a high-energy ball mill tank for 1.5 hours to obtain a mixed powder;

[0044] b) placing the mixed powder in a steel mold and applying a pressure of 300MPa to obtain a molded green body;

[0045] c) Place the shaped green body in a muffle furnace, heat it under argon gas at a temperature of 420° C., and keep it warm for 30 minutes, then take out the green body and place it in the extrusion cylinder of an extruder. 10:1, the extrusion speed is 1mm / s, the green body is extruded under the conditions of 600T pressure, and the magnesium alloy is obtained after water cooling.

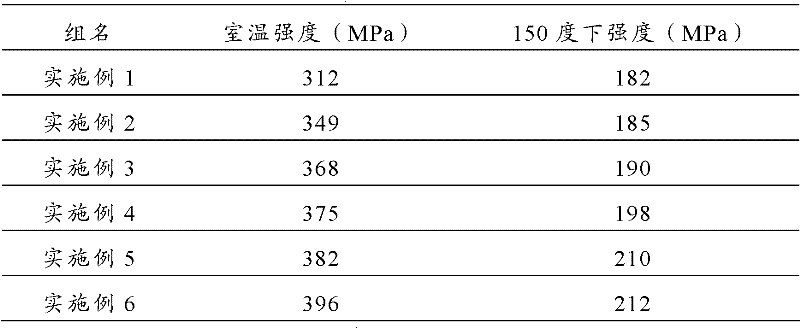

[0046] After the magnesium alloy prepared in Example 1 was polished, its room temperature strength and strength at 150 degrees were tested, and the results are shown in Table 1.

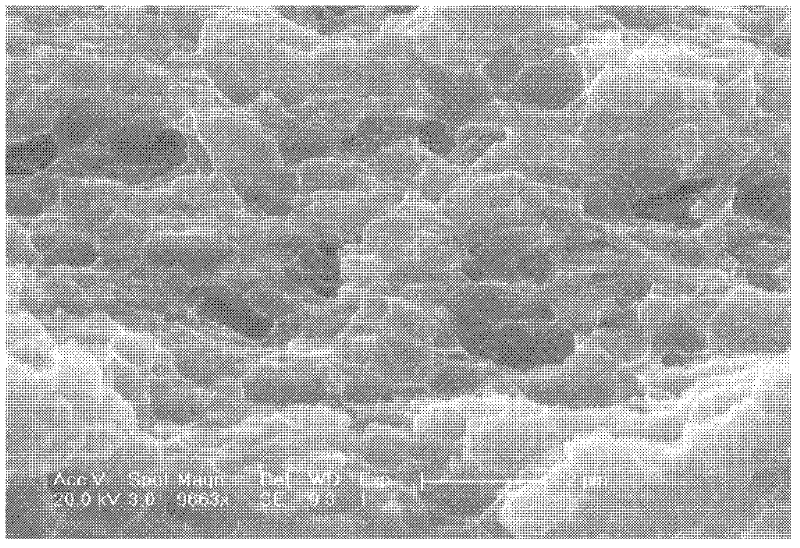

[0047] Scanning electron microscope analysis is carried out to the magne...

Embodiment 2

[0049] a) 4.88 grams of magnesium silicide nano powder, 2 grams of zinc powder, 10 grams of aluminum powder and 183.12 grams of magnesium powder were mixed in a high-energy ball mill tank for 1.5 hours to obtain a mixed powder;

[0050] b) placing the mixed powder in a steel mold and applying a pressure of 320MPa to obtain a molded green body;

[0051] c) Place the shaped green body in a muffle furnace and heat it under argon at a heating temperature of 430°C. After holding the heat for 40 minutes, take out the green body and place it in the extrusion cylinder of the extruder. 10:1, the extrusion speed is 1mm / s, the green body is extruded under the conditions of 600T pressure, and the magnesium alloy is obtained after water cooling.

[0052] After the magnesium alloy prepared in Example 2 was polished, its room temperature strength and strength at 150 degrees were tested, and the results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com