Novel micro-pressure sensor chip

A micro pressure sensor and chip technology, applied in piezoelectric devices/electrostrictive devices, instruments, piezoelectric/electrostrictive/magnetostrictive devices, etc. Increase linearity, reduce sensor accuracy, etc., to achieve good stress concentration, good economic and social benefits, and easy compensation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The technical solutions of the present invention will be described in further detail below through specific implementation methods.

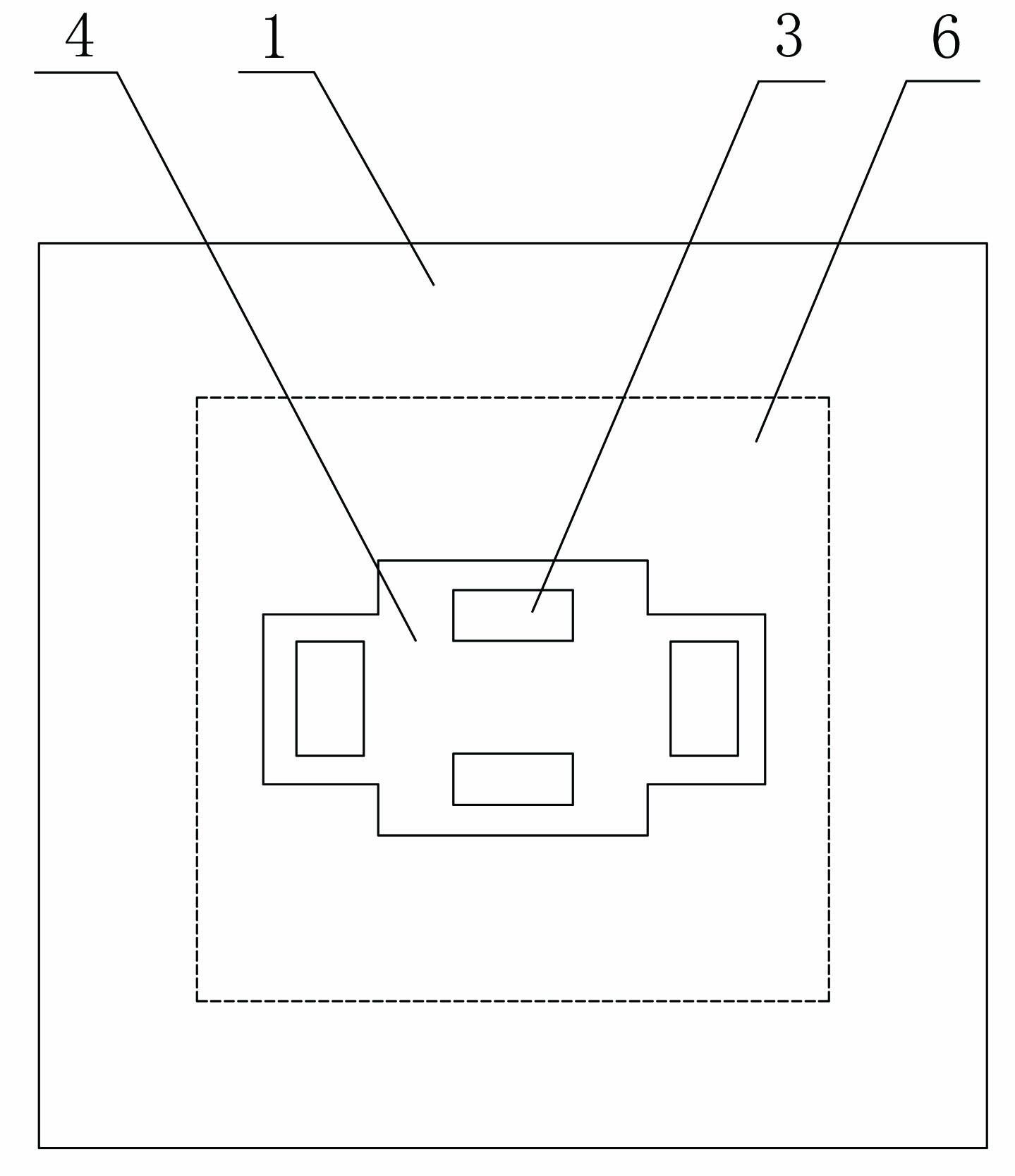

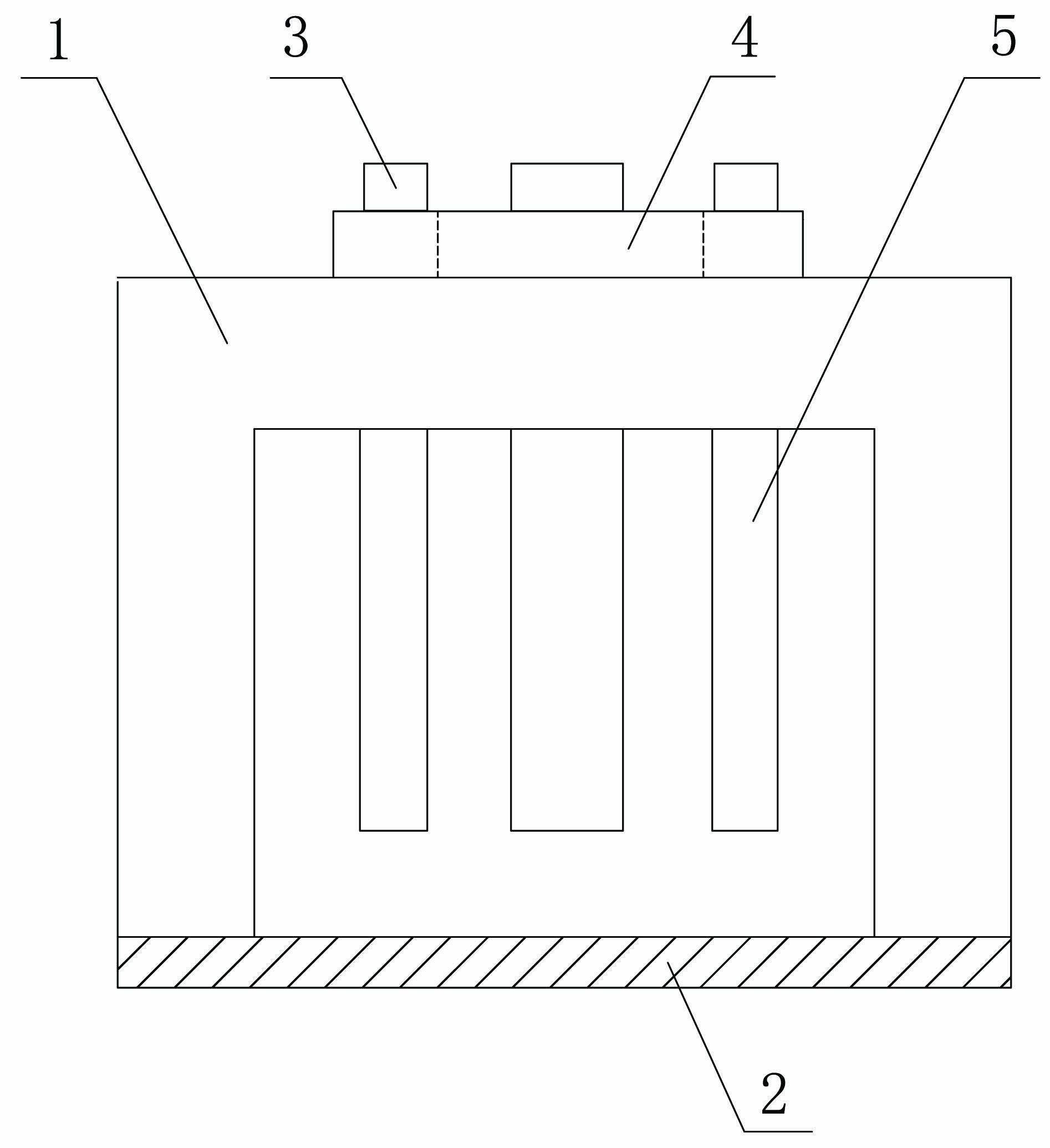

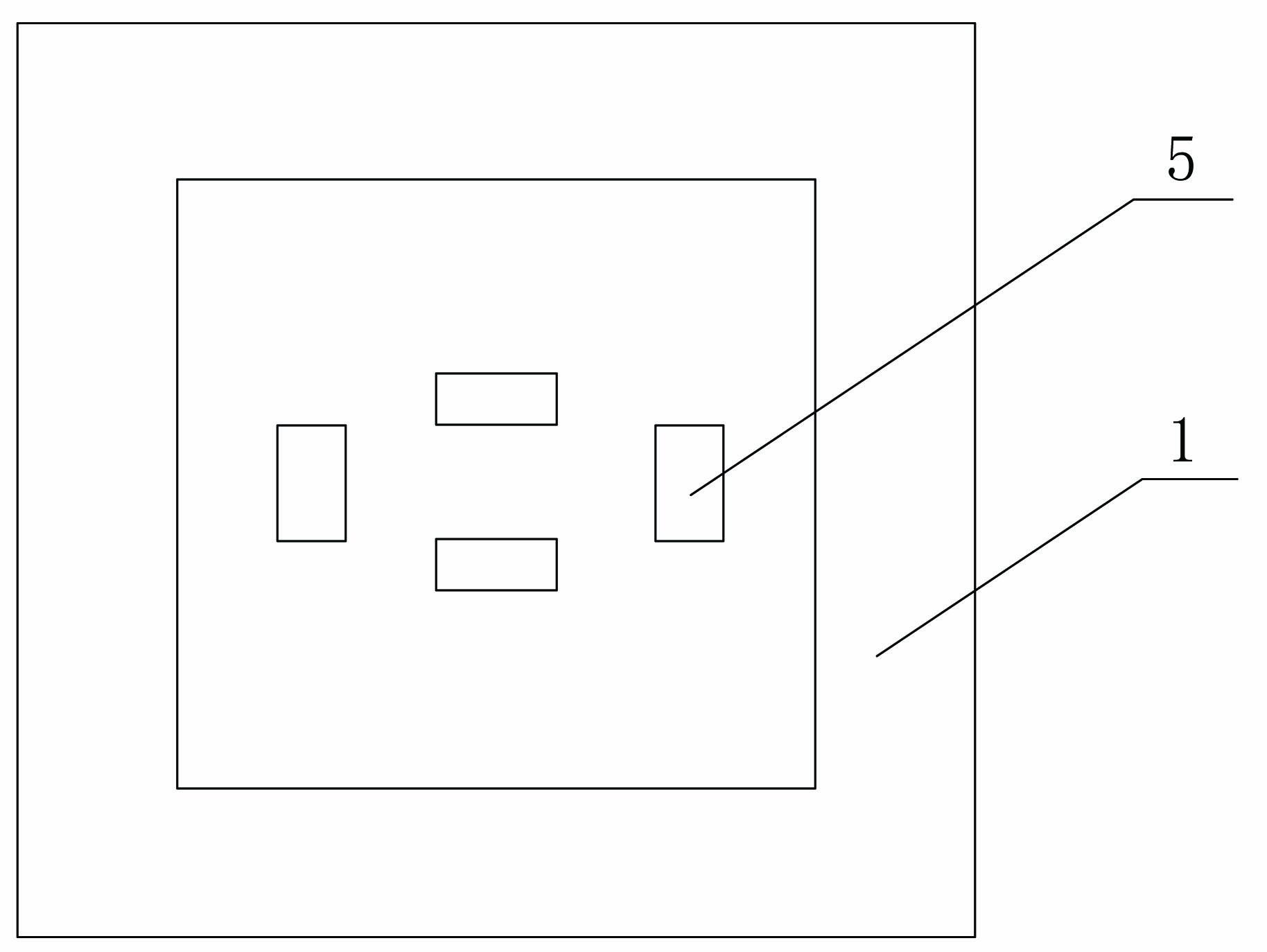

[0017] like figure 1 , figure 2 and image 3 As shown, a new type of micro pressure sensor chip includes a single crystal silicon chip 1, a base glass 2 and four force sensitive resistors 3, the front side of the single crystal silicon chip 1 is provided with a convex beam 4, and the four force sensitive resistors Resistors 3 are arranged on the convex beams 4 respectively; grooves are opened on the back of the single crystal silicon wafer 1, and four back islands 5 are arranged at the bottom of the grooves; the convex beams 4 correspond to where the grooves are located. Position setting: a rectangular frame is formed around the groove on the back of the single crystal silicon wafer 1, and the rectangular frame is electrostatically bonded and packaged with the base glass 2.

[0018] Specifically, the convex beam 4 is a cross-shaped fl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com