Method for observing metallographic structure of molybdenum-niobium alloy

A technology of metallographic structure and molybdenum-niobium alloy, which is applied in the field of observation of molybdenum-niobium alloy metallographic structure, can solve the problems such as difficulty in obtaining clear structure of molybdenum-niobium alloy metallographic samples, achieve sufficient grinding amount, easy operation, and reduce pits hole effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

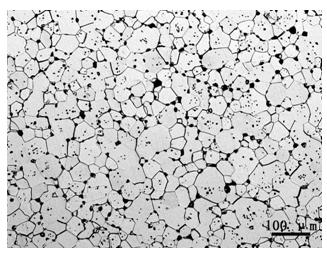

Embodiment 1

[0021] Metallographic structure observation method of 10mm×10mm molybdenum-niobium alloy plate. It is characterized in that the sample is firstly used in the grinding machine with 150 # , 700 # , 1000 # The metallographic water sandpaper is ground step by step, the sample after grinding is washed away the sand particles, the sample that has been ground is polished on a polishing machine, and after polishing, the sample is first treated with a solution of potassium ferricyanide:sodium hydroxide=1:2 by volume. Erase, etch for 8s, then use the volume ratio as H 2 SO 4 : HNO 3 :HF:HCl=1:1:1:0.5 solution erosion for 2s.

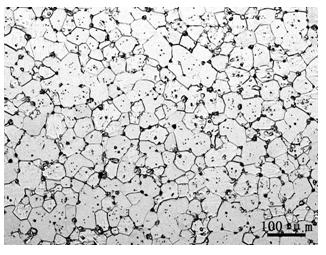

Embodiment 2

[0023] Metallographic structure observation method of 10mm×10mm molybdenum-niobium alloy plate. It is characterized in that the sample is firstly used in the grinding machine with 150 # , 700 # , 1000 # The metallographic water sandpaper is ground step by step, the sample after grinding is washed off the sand grains, the sample that has been ground is polished on a polishing machine, and after polishing, the sample is first treated with a solution of potassium ferricyanide:sodium hydroxide=2:2 by volume. Erase, etch for 14s, then use the volume ratio as H 2 SO 4 : HNO 3 : HF: HCl = 2: 1.5: 1.5: 0.5 solution erosion for 4s.

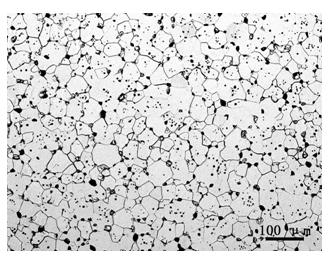

Embodiment 3

[0025] Metallographic structure observation method of 10mm×10mm molybdenum-niobium alloy plate. It is characterized in that the sample is firstly used in the grinding machine with 150 # , 700 # , 1000 # The metallographic water sandpaper is ground step by step, the sample after grinding is washed off the sand grains, the sample that has been ground is polished on a polishing machine, and after polishing, the sample is first treated with a solution with a volume ratio of potassium ferricyanide:sodium hydroxide=3:2 Erase, etch for 20s, then use the volume ratio as H 2 SO 4 : HNO 3 :HF:HCl=1:1:1:1 solution erosion for 6s.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com